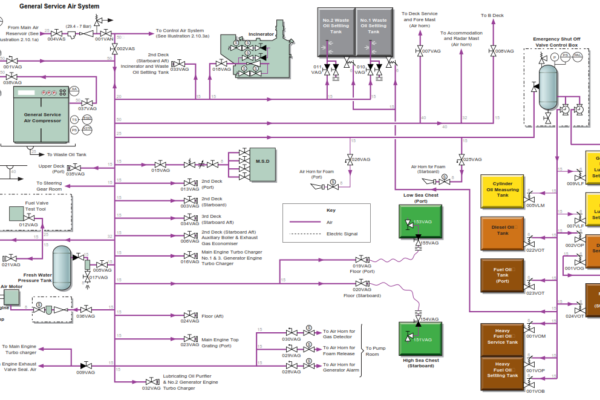

Pumps and pumping systems in Engine Room

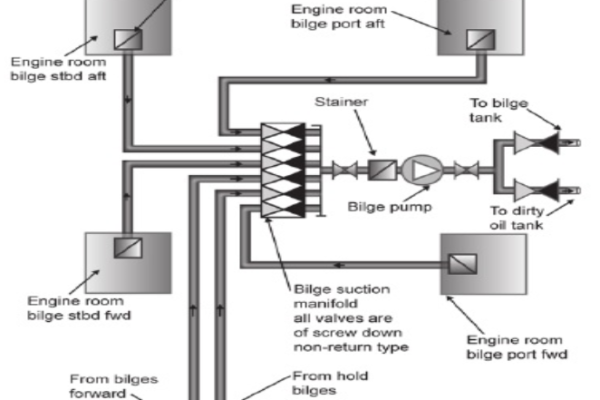

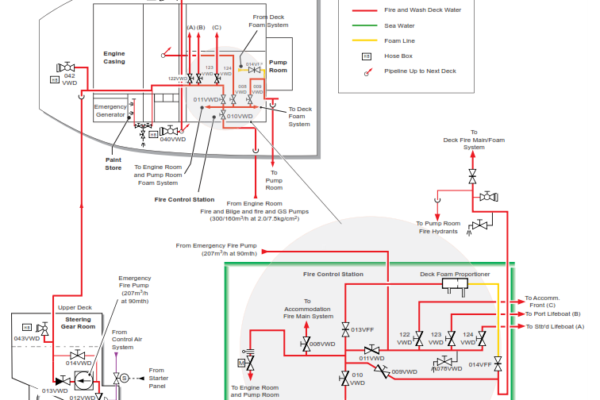

Piping system The bilge system is used to remove small quantities of fluid that have leaked or condensed into a dry space. The system serves the machinery spaces, cargo holds, cofferdams, voids, stores, tunnels and pump rooms. Each space has its own piping but the