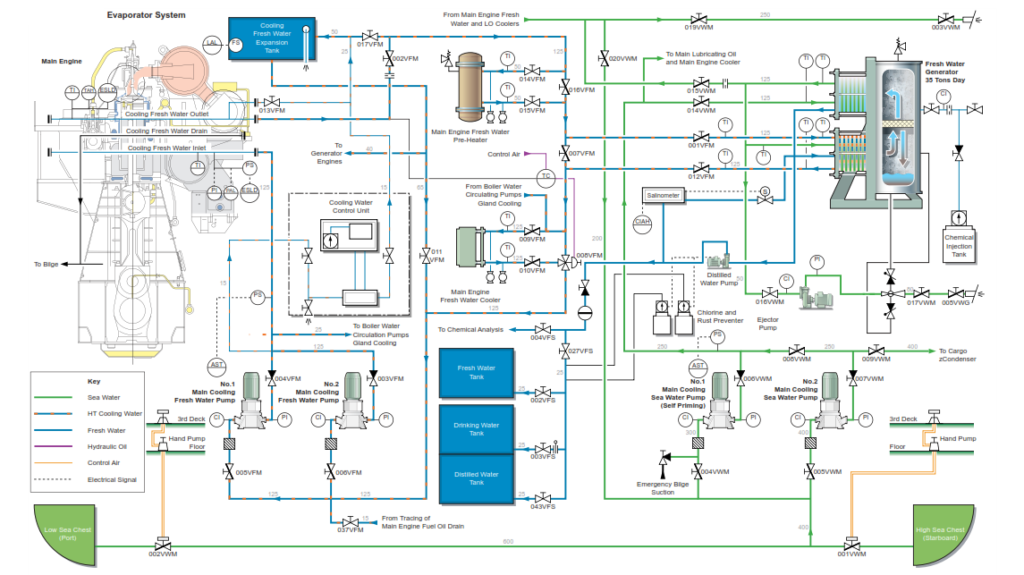

The fresh water generator (evaporator) installed in the engine room utilizes the heat available from the main engine jacket cooling water system to produce fresh water for use on-board the vessel. In doing so the evaporator acts as a cooler for the main engine jacket cooling water system thus reducing the load on the main engine jacket cooler.

The main engine cooling water is circulated through the heater at the base of the evaporator where it gives up heat to the sea water feed flowing through the tubes in the heater. The cooling water flows from the main engine into the evaporator and exits and returns to the cooling water circuit . Not all of the main engine’s cooling water passes through the evaporator as the bypass valve ensures that some of the water is bypassed. This valve should be throttled to allow some of the cooling water to bypass the evaporator and should never be fully closed during normal operating conditions.

To achieve low temperature evaporation and so improve the efficiency of the unit, the pressure within the evaporator chamber is under vacuum. This is achieved by the ejector that operates to remove, from the evaporator casing, brine and the gases liberated from the sea water feed during the heating of the sea water.

The feed water is introduced into the evaporating section of the evaporator and flows through the tubes in the heater where it absorbs heat energy from the circulating main engine jacket cooling water. Having reached boiling temperature, which is lower than at atmospheric pressure, the feed water undergoes a partial evaporation and the vapor passes to the condenser section at the top of the casing via a deflector and a demister mesh. The brine remaining is removed from the evaporator casing by the combined brine and air ejector that is supplied with driving sea water by the dedicated ejector pump.

After passing through a demister the vapour enters the condenser where it is condensed by sea water. Some of the sea water used in the condenser is used as feed sea water for the evaporator as it has been heated in the condenser and the use of warm sea water for feed purposes improves the operating efficiency of the evaporator.

Fresh Water Quality

To check the quality of the fresh water that has been produced, within t5he evaporator, a salinometer has been provided which continuously monitors the distillate at the outlet from the distillate pump. If the salinity of the fresh water exceeds the chosen maximum value, the dump valve and the alarm are activated and the water is returned to the evaporator chamber to be reprocessed.

Main Components

The evaporator consists of the following components:

Heater Section

The heating or evaporating section of the unit consists of a tubular heat exchanger that is fitted inside the casing at the base of the evaporator. Hot main engine jacket cooling water circulates around the tubes and the sea water flows through the tubes from the bottom to the top.

Evaporator Vessel

The evaporator chamber is located at the top of the heater and this is where the water vapour is liberated from the brine. The brine ejector suction is located in the evaporator chamber and the brine ejector maintains the correct brine level by removing excess brine. The brine ejector also removes the gases liberated from the sea water when it is heated and so the vacuum is maintained.

At the top of the evaporator chamber is a deflector plate which directs the vapour to the demister screen located at the top of the evaporator section. This screen separates the evaporator section from the condenser section.

Condenser Section

The condenser is mounted above the heater close to the top of the unit and this is where the vapour is condensed into water. The condenser is a tubular unit through which sea water flows from the duty main cooling sea water pump. The cold sea water condenses the vapour and this distillate falls to the collection tray at the base of the condenser unit. The distillate is then removed from the evaporator by the distillate pump and discharged to one of the holding tanks.

Combined Brine/Air Ejector

The ejector uses sea water as its driving medium and extracts brine and incondensable gases from the evaporator.

Ejector Pump

The ejector pump is a single-stage centrifugal pump that supplies the brine/air ejector with operating water. The water supply comes from the duty main cooling sea water and the ejector pumps boosts the pressure to drive the ejector.

Distillate Pump

The distillate pump is a single-stage centrifugal pump that extracts the fresh water produced from the condenser and pumps it to the distilled, drinking and fresh water storage tanks.

Salinometer

The salinometer continuously checks the quality and salinity of the fresh water produced and notifies the duty engineer if the salinity has exceeded a pre- defined set point of 10ppm. The alarm for this set point is adjustable through the local control panel.

Control Panel

A control panel contains motor starters, running lights and contacts for the remote alarms. A salinometer control panel is located at the evaporator side with a salinity indicator (reading in ppm). The panel also contains a 5ppm test pushbutton and control pushbuttons to set the alarm point.

Chemical Injection Unit

Care must be taken when handling feed water treatment chemicals to avoid direct skin, eye or clothing contact. Approved eye protection and gloves MUST be worn at all times. In the event of accidental contact, seek medical attention immediately.

The unit is fitted with a chemical injection unit which connects into the sea water feed inlet side of the evaporator’s heater. The unit is operated by a Iwaki type EH-R electromagnetic pump and the injection of treatment chemical is intended to inhibit foaming and control the formation of scale on the heating surfaces thereby allowing prolonged operation without the need for a plant shutdown for cleaning.

Evaporator Operating Procedures

Do not operate the plant in restricted waters if the water produced is to be used for human consumption. There are strict regulations governing the operation of fresh water generators near coasts and estuaries and these should be observed. Contact the bridge for information regarding these restrictions when the ship is in coastal waters.

Starting and Stopping Procedures

The evaporator must only be operated when the main engine is operating at normal full power when sufficient heat will be available in the engine jacket cooling water.

a) Ensure that power is available and that the alarm and control panels are switched on.

b) Set the valves as follows. It is assumed that the engine room sea water crossover main is already open, that one of the main cooling sea water pumps is operating and that the system is discharging distillate into the distilled water tank.

| Position | Description |

| Open | Evaporator sea water inlet valve |

| Open | Evaporator sea water outlet valve |

| Open | Overboard discharge line valve |

| Open | Overboard discharge valve |

| Open | Sea water feed valve to evaporator |

| Open | Chemical treatment inlet valve |

| Open | Evaporator ejector pump suction valve |

| Open | Ejector overboard discharge line valve |

| Open | Ejector overboard discharge valve |

| Closed | Evaporator jacket cooling water inlet valve |

| Closed | Evaporator jacket cooling water outlet valve |

| Open | Evaporator jacket water bypass valve |

| Open | Distillate pump outlet valve |

| Closed | Chemical dosing unit line valve |

| Open | Distillate flowmeter outlet valve |

| Open | Distilled water tank filling valve |

| Closed | Drinking water tank filling valve |

| Closed | Fresh water tank filling valve |

c) Close the air vent valves on the evaporator and ensure that there is sea water circulating through the evaporator system.

d) Ensure the feed water inlet valve allowing water into the heater is open. Control the feed water rate within the green range on the compound gauge.

e) Start the ejector pump and create a vacuum of at least 70cmHg in the evaporator casing. This should be developed in less than 10 minutes.

f) Ensure the chemical injection tank is topped up with the correct amount of chemicals at the correct concentration. Open the feed water treatment valve and start the dosing pump.

g) When the evaporator vacuum has reached 70cmHg, open the evaporator jacket water inlet valve and slightly close in the bypass valve . Open the evaporator jacket water outlet valve ; this valve should be opened gradually to avoid sudden overheating of the heat exchanger. The boiling temperature will rise and the vacuum will fall to approximately 50cmHg indicating that evaporation has commenced. After about 3 minutes the temperature will fall and the normal vacuum will be restored. Adjust the jacket water inlet and bypass valves until the desired temperature is reached; the evaporation temperature should be in the range 45°C – 60oC.

Note: Too high an evaporation temperature increases the risk of scale formation in the evaporator

h) Switch on the salinometer and check for correct operation.

i) Start the fresh water/distillate pump

The evaporator will now operate automatically and discharge distillate to the distilled water tank provided that the quality is above the base level set on the salinometer. Should the quality fall, the salinometer will activate an alarm and direct the distillate to the brine chamber of the evaporator for re-evaporation. When the quality returns to an acceptable level the salinometer will close the recirculation valve and output will flow to the distilled water storage tank.

The output of the evaporator can be adjusted by regulating the flow of jacket water to the evaporator by adjusting the evaporator jacket water bypass valve and the jacket water inlet valve.

Stopping the Evaporator Plant

To stop the fresh water evaporator plant proceed as follows:

a) Stop the hot water supply to the unit by closing the evaporator jacket cooling water inlet and outlet valves and by fully opening the bypass valve .

b) Close the feed water treatment valve (if open).

c) Close the inlet and outlet valves to the heat exchanger.

d) Stop the distillate water pump.

e) Switch off the salinometer.

f) Close the feed water valve.

g) Stop the ejector booster pump.

h) Close the condenser inlet and outlet valves

i) Open the air vents on the separator.

j) Close the inlet valve to the distilled/drinking/fresh water tanks as necessary.

2 thoughts on “FRESH WATER EVAPORATOR”