Oil Fired Auxiliary Boilers

The oil fired auxiliary boilers are not fitted with sootblowers. Soot removal from the heat transfer surfaces of the tubes is carried out by means of a water jet when the boiler is not in operation. The need for soot removal may be determined by the following procedures:

• Visual inspection of the tube surfaces

• Measurement of the exhaust gas temperature; if the exhaust gas temperature after the boiler is more than 10 – 20oC higher than the exhaust gas temperature for a clean boiler at the same firing rate, tube cleaning is required

• Measurement of the ventilated air pressure drop. If the pressure drop is 10 – 20mmWG higher than for a clean boiler tube cleaning is required

Procedure for Soot Removal by Water Washing

a) Stop the boiler burner operation and allow the boiler to cool for10 – 20 minutes.

b) Open the soot drain valve at the base of the furnace and open the checking hatch of the flue box at the top of the boiler.

c) Connect the water jet cleaning lance to a fresh water supply and direct a water jet at a pressure of 0.4 to 0.6MPa into the smoke tubes; the flow rate should be about 50 litres/min. The water jet should be directed into the smoke tubes for about 20 – 30 seconds and care should be taken to prevent water impinging on the boiler burner nozzle.

d) Turn the water supply off after cleaning and ensure that all water and soot drain through the soot drain valve.

e) Repeats step c) and d).

f) Visually check through the checking hatch that the surfaces of the tubes are clean and repeat steps c) and d) again if necessary.

g) When the tube surfaces are clean and the water/soot has been discharged from the furnace, close the soot drain valve and the checking hatch of the flue box.

h) Start the burner under low load to dry the tube surfaces.

i) After operation of the burner for 5 – 6 minutes stop the burner and open the soot drain valve to discharge any further water/ soot.

j) Close the soot drain valve and operate the burner for 10 – 15 minutes ensuring that the boiler exhaust gas temperature is within limits.

k) Stop the burner and open the soot drain valve to discharge any further water/soot.

l) Close the soot drain valve and check the tightness of the checking hatch of the flue box.

m) The boiler is now ready for further service.

Exhaust Gas Economiser

Four sootblowers are fitted to the exhaust gas economiser. These are mounted on the side of the economiser and the lance of each sootblower penetrates into the tube bank. The sootblowers are manually operated by means of an operating handwheel, the steam supply check valve having first been opened. The handwheel is rotated left and right between the stoppers to ensure that the sootblower operates over its entire blowing range.

Steam is supplied to the sootblowers from the supply valve on the 0.88MPa range; the economiser operates at a pressure of 0.49MPa and so this will be the supply steam pressure to the economiser sootblowers. The supply line drain valve must be open at all times when steam is not being supplied to the sootblowers.

Sootblowing has to be carried out at regular intervals to ensure that the heat transfer surfaces are kept clear of deposits, as these retard heat transfer and can constitute a fire hazard. Sootblowing of the economiser should be carried out every 6 hours at sea although the frequency depends upon the quality of fuel being burned in the main engine.

Procedure for the Operation of the Exhaust Gas Economiser Steam Sootblowers

a) The main engine should be at a minimum of 50% of full load.

b) Ensure that there is a sealing air supply to the sootblowers, this should be open at all times.

c) Open the sootblower manifold drain valve and then open the sootblower steam supply valve . When all water has drained from the drain valve close the drain valve.

d) The sootblowers may now be operated individually by opening the sootblower steam supply valve and turning the sootblower operating handwheel fully to the left and then the right until the handwheel encounters the stops. Rotation of the handwheel to the left and right stops must be repeated several times.

e) The lower sootblowers should be operated first and then the upper sootblowers.

f) When sootblowing is complete at all sootblowers ensure that the sootblower steam valves are closed, open the sootblower supply manifold drain valve and close the steam supply valve . The drain valve should remain open except when the sootblowers are being used.

Procedure for the Operation of the Exhaust Gas Economiser Water Wash

In addition to the steam sootblowing of the economiser during sea passages, the economiser may be water washed when the main engine is stopped.

a) Ensure that the main engine cannot be started

b) Open the inspection doors on the economiser and visually inspect the condition of the soot deposits on the pin tubes.

c) Stop the boiler water circulation pump.

d) Open the upper access plate

e) Open the exhaust gas uptake access plate

f) Using the dedicated spray gun, at a water pressure of 0.2 to 0.3MPa wash the tubes. Continue the wash until no further soot is being dislodged.

Note: The water consumption should typically be in the region of 5 litres per square meter of heating surface.

The water will run down the economised and the main engine exhaust gas uptake into the pipe which leads the water to the soot collecting tank.

CAUTION:There is a space approximately 0.4m in depth below the height at which the uptake enters the vertical section of the flue to ensure no water can make its way into the main engine, however an inspection of this space should maintained to ensure the level does not rise to the point where water can run down to the engine.

g) Start the boiler water circulating pump and run for an hour or until the pin tubes are completely dry.

This will have the effect of expanding the tubes and flaking off the majority of the remaining carbon adhering to the tubes. This dry carbon is collected manually via the lower access cover from the recess space in the flue.

h) When no flakes fall, stop the boiler water circulating pump and repeat the washing and water circulating cycle until the tubes are clean.

i) Resume circulating water with the boiler water circulating pump if required.

i) In completion of the procedure visually inspect the internal surfaces of the economiser tubes and ensure that no tools, rags etc. remain inside. Close the access covers.

This process should be completed on a frequency of 2 to 3 times a year and will depend on the amount of manoeuvring the main engine is required to do.

The soot collecting tank may be pumped out using the dedicated eductor fed from the sea water service system..

Note: On the first passage following economiser waterwashing it is common for sparks to be emitted from the main engine exhaust stack, so the wheelhouse watch should be advised accordingly.

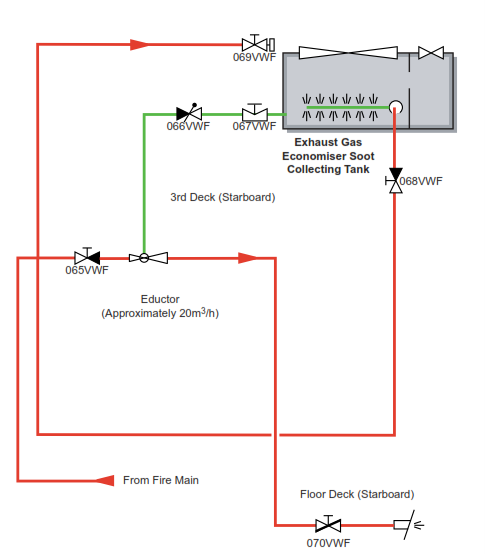

Procedure for Pumping Out the Exhaust Gas Economiser Soot Collection Tank

The exhaust gas economiser soot collection tank may be pumped overboard when approval has been given by the Chief Engineer for such pumping. The contents of the tank are pumped out by means of an ejector which is operated using water from the fire main. The water from the fire main is also used to stir up and wash out the contents of the tank to allow for easier discharge.

Exhaust Gas Economiser Soot Collecting Tank

Note: the pumping of the economiser soot tank will be undertaken every time an economiser water wash is undertaken, which under normal operating conditions should be in the region of every four to six months. The solid residue will be almost pure carbon and is similar in nature to the solids washed from the scrubber tower and therefore not subject to discharge restrictions.

a) Ensure that the fire main is pressurised..

b) Confirm with the bridge that approval has been given for the discharge of the contents of the economiser soot collection tank.

c) Open the shipside overboard discharge valve .

d) Open the outlet valve from the economiser soot collection tank.

e) Open the flushing water supply valve to the economiser soot collection tank and allow sea water into the tank.

f) Open the operating sea water supply valve to the economiser soot collection tank ejector.

g) The ejector will operate to discharge the contents of the tank overboard and the flushing sea water will remove all traces of soot from inside the tank.

h) When the soot has been removed from the tank and the overboard discharge is running clear, close the flushing water valve and allow the ejector to drain the remaining contents of the tank.

i) When the soot collection tank is empty close the ejector operating water valve , the collection tank outlet valve and the overboard discharge valve .

j) Record the discharge in the engine room log book