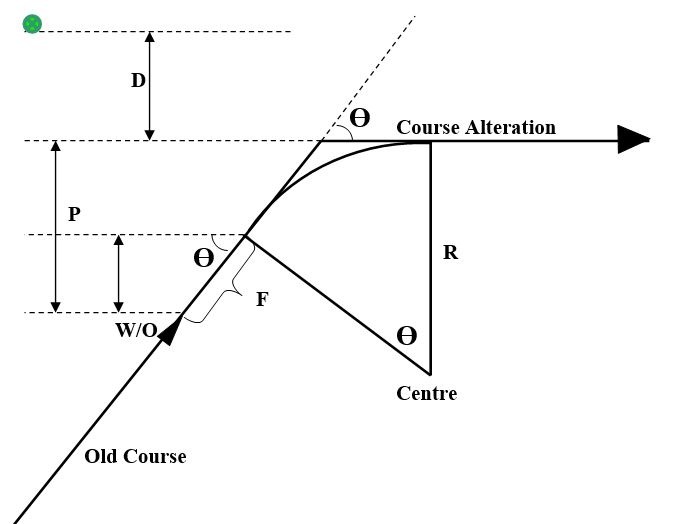

Wheel over position calculation

Wheel over positions should be determined from the ship’s manoeuvring data and marked on the chart. Suitable visual & radar cues should then be chosen to determine when the ship is at the wheel over position. The best cues for large alterations of course consist of Parallel Indexes or visual bearings parallel to the new…