After studying this blog, you should be able to:

- Identify how to apply flow chart principles for any hazardous work e.g. the Enclosed Spaces on board your ship.

- Evaluation of work processes such as the safety of accesses to and from enclosed spaces.

- Explain thoroughly concepts and processes under Operational Risk Management (ORM).

- Apply ORM to jobs assigned in and around enclosed spaces.

Means of access to and from enclosed spaces on board ships have posed serious hazards and the ensuing risk factor analysis, formed a major part of the operational process required to manage the Ask.

Over the years, a considerable amount of experience factors have been compiled on the hazard, but unfortunately, not before several fatalities involving such spaces on board ships have occurred. An example being a series of disastrous oil tanker explosions in the mid-seventies, during tank cleaning. After extensive investigations into these explosions, inert gas systems (IGS) were developed and by the mid-eighties instances of such incidents sharply deteriorated and the hazard controlled.

In the previous chapters, work flow mapping to identify and analyze risk was discussed, followed by the issue of personifying safe practices. Ship board orientation programmes for freshly joining seamen, outlines the ship-specific layout plans for enclosed spaces and its access, for effecting work processes. The personalization of such programme benefits, and creates conditions for application and therefore a personalised safety technique and culture.

Enclosed Spaces

An enclosed space or confined space is defined as an area within which life supporting oxygen has been depleted for a variety of reasons, ranging from oxidation, due to corrosion or the property of cargoes, shutting out of ventilation over prolonged periods to spaces such as cofferdams, pipe ducts and their escape trunks, to hot work carried out in such spaces that effectively depletes oxygen content through the release of pyrolysis products. (Pyrolysis products are released during hot work (Examples being welding, arc gouging and flame cutting). Examples of such products are Lead metal fumes, Nitrogen-di-Oxide etc)

Common examples of enclosed spaces on board ships are:

- Double bottom and peak tanks.

- Hopper and top-side wing tanks.

- Cofferdams and such like void spaces.

- Paint and Battery storage rooms.

- Septic Tanks.

- Cargo holds and tanks, especially so when holds have been fumigated and ventilation suspended etc.

Access

Access provides the means to approach and enter an enclosed space. Conversely, access also provides means to escape out of the enclosed space. This definition being so common place and fundamental in its understanding is often overlooked in practice resulting in disastrous events. An emergency escape is provided as means by which the bottom-most flat in the engine room can be evacuated to reach safe assemblage points on open decks. A series of vertical trunkings and horizontal aisles form the escape route which, at all times, should be

- Well lit in order to illuminate the route and door-way handles.

- Pasted with retro-reflective directional arrows leading to safe open decks.

Despite these clear cut guidelines, seafarers often misuse or even alter accessways to cater to specific situations. Threats such as transiting piracy infested channels or ports frequented by thieves and thugs may require that the access doors are limited and controlled in order to manage the threat perception. However, after the threat is over, reversal of controlled measures is not carried out and soon degenerates and access remains blocked permanently. Similarly, access pathways get obstructed when repairs are in progress. After completion of the work, it is important to clear the obstruction and keep the passage ways free as planned. One never knows when an emergency unfolds!

The ORM Concept

“ORM” stands for Operational Risk Management and has for application, a variety of shipboard operations such as working in and around enclosed spaces.

Uncertainty and risk are inherent in the nature of shipboard activities in general and working in and around enclosed spaces in particular. The safe outcome of enclosed space operations is based upon an initiative to balance the risk with clear and decisive risk minimising measures. In doing so, a fundamental responsibility comes to bear upon the operations in-charge to safe guard valuable life and limb and accordingly accept only the minimal level of risk, necessary to accomplish the assigned task.

ORM is an effective tool in achieving assigned tasks within hazardous spaces requiring a high degree of safety, which otherwise, is detrimental to potential capabilities on part of the shipboard compliment. It is a decision-enhancing programme. ORM should be used by team leaders at all levels to increase operational efficiency by anticipating hazards and reducing loss potential. Furthermore, it increases the ability to make informed decisions by making available optimum baseline knowledge and experience. Through ORM, risk factors are brought down to acceptable levels commensurate with job accomplishments. An example in point being the quantum of risk taken during hold cleaning operations at sea is much greater than conducting same in port or enclosed waters, whilst at all times the operational processes being the same.

ORM Principles

ORM incorporates the following four principles:

- Risk acceptance is subject to the benefits outweighing the costs. We are aware that risk is inherent in all shipboard activities. Experience has shown that risk is also directly proportional to gain. Seafaring tradition has all along dictated that the initiative be seized by taking decisive action at the right opportunity. ORM empowers team leaders to walk through the process by managing (as opposed to eliminating) risk until the successful completion of the task with minimal losses.

- Unnecessary risk acceptance is an absolute ‘NO-GO’ alternative. A fundamental principle which merits a clear understanding is that, “the acceptance of risk does not equate the imprudent willingness to gamble…” Only those risks which are necessary to achieve the task on hand should be taken and only after due consideration to managing it

- Risks are more easily controlled when they are identified early in the planning process. Once the risks are identified, they can be managed through creation of operational work-flow charts and check-listing.

- Risk management decisions are made by the operational team leaders responsible for the accomplishment of the assigned task. Prudence, experience, judgment, intuition and most importantly situational awareness of team leaders directly involved in the planning and execution of the task are critical to the quality of effective decision making. When team leaders are confronted with frontline risk escalation beyond what was anticipated, the team leader should never shy away from seeking additional guidance from his superiors, may it be Master, Chief engineer or a shore authority.

The ORM Process Flow-Chart

| Steps | Task | Sub Tasks |

| 1 | Hazard identification | – Analyse Hazard – Cause of Hazard |

| 2 | Hazard Assessment | – Probability of occurrence. – Severity of occurrence |

| 3 | Risk Decision-Making | – Prioritise risk – Select control measures – Conduct risk-benefit analysis |

| 4 | Risk Control- Implementation | – Engineering. (Design & Materials) – Administrative. (Policy, Notices Warnings etc.) – Training Programme |

| 5 | Personal Protective Gear | – Creating barriers between personnel & Hazards |

| 6 | Supervision | – Periodic evaluation of controls to ensure adherence to desired effect – Monitor for changes in situational circumstances. |

ORM Levels

The Operational Risk Management process exists on three levels namely:

- Time critical

- Deliberate

- In depth

The deployment of these levels should be on consideration of the following steps:

- The job complexity on hand.

- The operational situation.

- The time-frames available.

- The proficiency level of the team members.

- The equipment’s available to execute the task.

While it would be preferable to perform an in-depth risk management process for all ship board activities, this may not be always possible due to time and resource constraints. One of the prime objectives of ORM training is to develop sufficient proficiency in applying the process, such that the programme becomes an automatic or intuitive part of decision making methodology. In the operational environment, team leaders should be able to employ this time-critical process to make sound decisions that generate tempo and facilitate safe outcomes.

The three levels of ORM processes are

- Time-Critical: A mental mapping or oral overview of the situation, using the five step process with out recording the information on paper. The time-critical level is utilised by experienced team leaders to consider risk factors while making decisions in a time-critical situation. Planning a crisis response action requires team leaders to choose the appropriate course of action when an unplanned event has occurred during the execution of routine shipboard tasks. An example of such a crisis response action would be the deployment of a rescue and retrieval team to bring out injured members of a repair team deployed in an enclosed space. Who should go into the space? How many members should go into the space?

- Deliberate: Application of the complete five step process in planning an operation or evaluating a procedure conforms to the Deliberation level. It primarily calls upon the experience and collective brainstorming acumen in order to identify hazards and develop control measures and is, as such, most effective when done in teams drawn from members of different functions (Navigators, Engineers, Electricians, Flying Squad Repair Teams etc.) Examples of such level of ORM is the review of standard operating procedures (SOP), damage control and disaster response planning or maybe even an planning a hold cleaning programme for which very limited time is available.

- In-Depth: The level of Deliberation with a more thorough risk assessment of the first two steps of the five processes, namely, the job complexity on hand and the operational situation constitutes an In-Depth level of the ORM programme. The level involves drawing upon research of available data, the use of work flow charts , formal testing or long term tracking of hazards associated with operational aspects (sometimes calling upon the services of Technical Experts in the related field) with an aim to identify and assess hazards. This level of the ORM programme is also used to study hazards and their associated risks in a complex operation or system or one in which the hazards are not well understood and in the introduction of new equipment features. Examples of the application of such levels in ORM programming is the evolution of the Anti-Collision Radar and plotting systems, known as ARPA. The risk of collision in poor visibility has been looming large over maritime shipping ever since the Titanic struck an iceberg. The risk persisted through a series of similar collisions between fully laden passenger ships, with disastrous consequences involving colossal loss of lives and property.

The ORM Approach to Enclosed Spaces

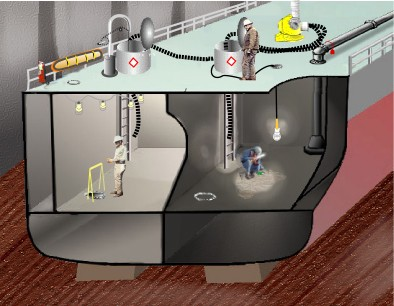

Enclosed spaces are life threatening in as much as its oxygen deprivation characteristics. In the case of enclosed cargo spaces, combustible and toxic gases may also be present. Access to and from enclosed spaces are sources of potential hazards with respect to its layout and illumination. In addition, the accesses may not be a permanent fitting and therefore pose further risks.

A typical job description involving enclosed spaces and access ways divides itself into operations and work-equipment’s sections. The ORM process commences application at the planning stage and continues to apply right through the execution and the follow-up feedback stages.

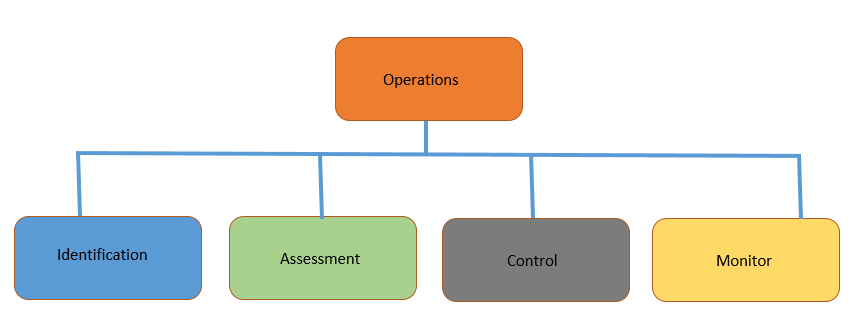

ORM PROCESS

Risk identification and assessment is determined by check listing the operations. The check list serves dual purpose of identifying and assessing the risk. For example when check-listing ventilation, the risk of oxygen depletion is identified, the duration and extent of ventilation is made only after the assessment and feedback.

Check List

- Has the space been ventilated?

- Will the ventilation be continued during the time the working team is in the space?

- Have pipelines to the space been cleared?

- Have valves serving the space been closed and lashed?

- Have appropriate placards for indicating danger areas and warnings displayed?

Placards are notices across different functional areas to warn of dangers and or proper accesses etc.

Work Equipment Section.

“Approved “means approved by an authority such as the Government or classification society. A certificate is issued to confirm the tests.

Check List

- Is adequate approved-type lighting available?

- Are portable lights of approved type?

- Will staging or ladders be used and if so are they adequate?

Risk controlling and monitoring enclosed space operations as part of the ORM process is achieved through warning notices, operating instructions (SOP) and permits to enter etc.

Preparation – Check-List:

- Has the space been gas freed and Oxy-Analysed?

- Has the space been tested and the results been documented and made readily available?

- Have persons entering enclosed spaces been provided with necessary safety equipment?

- Will a responsible person be available at the entrance to the space at all times?

- Is equipment for rescue and resuscitation available at entrance to the space?

- Are entry teams:

- Aware that check listing as above have been satisfactorily completed?

- Well versed in operating breathing apparatus?

- Allotted time to personally test the breathing apparatus with special attention to the Pressure Gauge accuracy indicating fully charged bottles and the low air alarms?

- Aware that the valves serving the space are TAG/LOCKED -OUT and the necessary instructions posted at the appropriate place?

- Familiar with the agreed communication system and emergency signals with the person standing by?

- Authorized to enter the space after submitting the completed checklist?

Ultimately, it is the responsibility of each individual to ensure the level of personal safety and that collective team safe practices are well understood and strictly adhered to in the true spirit of seamanlike traditions.

Enclosed spaces are potential risks and if it were not managed, fatalities would be waiting to happen. ORM is a well structured tool to minimize such risks. The integration of enclosed spaces operations with the ORM process is a specialized ability and developing such ability amongst seafaring personnel is an asset to team working on board ships.

As a shipboard career progresses, tasks get more complex in terms of its operational and commercial management. However, the basic concepts and processes under ORM remain the same.