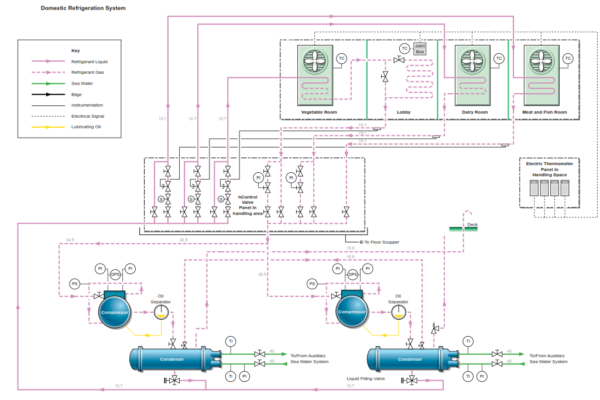

DOMESTIC REFRIGERATION SYSTEM

Cooling for the meat/fish, vegetable and dairy rooms is provided by a direct expansion R-404a refrigeration system. The plant is automatic and consists of two compressors, two condensers and an evaporator coil in each of the three cold and cool rooms; the lobby is cooled