The incinerator consists of a combustion chamber with burner unit, sludge burning equipment and electric control panel all assembled in one complete unit.

The incinerator can burn solid garbage waste, engine room waste oil and diesel oil to assist the total combustion when required. The unit is capable of burning approx 58-70 kg of waste oil per hour or 30kg/h of compacted solid waste or a combination of both to a maximum of 581kW heat generation. Waste oil may contain up to 40% water and burn without assistance and may contain up to 70% water if combustion assistance from the pilot burner is used.

The incinerator body is a horizontal, double casing cylinder with an external air chamber and an internal refractory wall. The high temperature obtained at the internal refractory enables waste oil with high water content to be burned readily.

The furnace front has a waste oil burner, a pilot burner, flame eye, ash removal door and pilot burner pump. The solid waste feeding door is located at the furnace side. The waste oil pump, waste oil strainer and diesel oil strainer are located below the furnace as is the combustion chamber exit where the diluting damper is fitted; this damper provides for cooling of the exhaust gas.

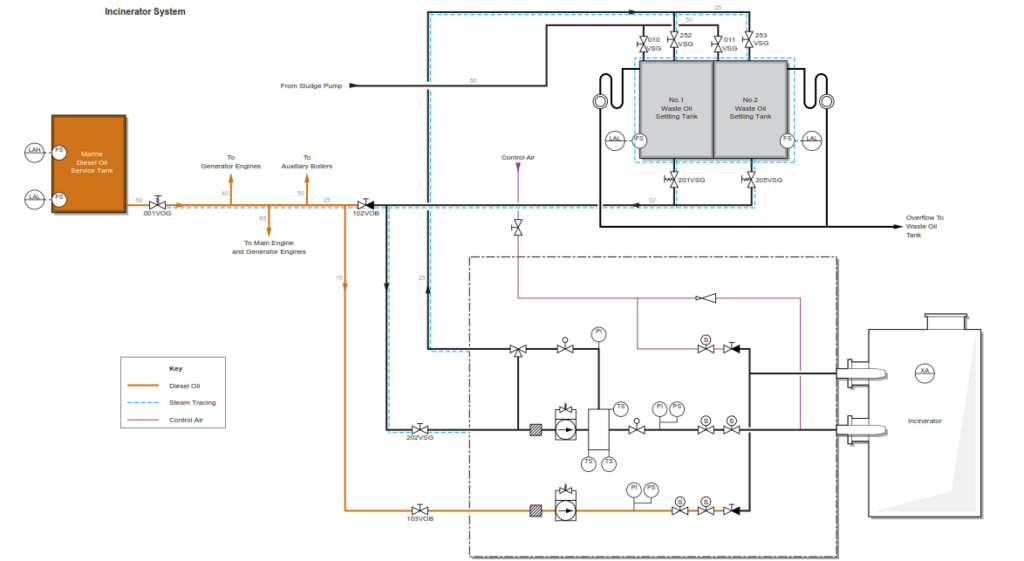

An induced draught fan is located on top of the incinerator body and this maintains a negative furnace pressure allowing for effective control of the combustion air to the furnace and diluting air to the exhaust gas. Waste oil is supplied to the incinerator from one of two waste oil service tanks which are steam heated.

When the incinerator receives a start signal the waste oil pump and induced draught fan will start allowing for waste oil circulation and purging of the furnace. The pre-purge lasts for about 10 seconds and 20 seconds after the start signal the pilot burner starts. When the flame eye detects the flame of the pilot burner the combustion indicator lamp illuminates and 7 seconds after the pilot burner ignites the waste oil shut-off valve is opened and injection of waste oil takes place. The pilot burner is extinguished 60 seconds after stable ignition of waste oil takes place; a cooling air supply is directed to the pilot burner atomiser for 30 seconds after the pilot burner is extinguished.

When the furnace temperature has increased to 1,000oC (the OFF set point for waste oil burning) the waste oil shut-off valve closes to shut down the waste oil burner. When the furnace temperature falls to 900°C (the ON set point for waste oil burning) the waste oil shut-off valve opens to restart waste oil burning.

During the ignition period if the flame eye does not detect a flame within 10 seconds after ignition of the pilot burner, the pilot burner and waste oil supply are shut off resulting in illumination of the ignition failure lamp and activation of the ignition failure alarm. The furnace purges and the induced draught fan stops if the furnace temperature is below 50°C; if the furnace temperature is above 50oC the induced draught fan remains operating until the furnace temperature falls to 50°C. It is not possible to restart the incinerator whilst the ignition failure lamp remains illuminated; the cause of flame failure must be found and corrected with the ignition system reset before another start is allowed.

The burning of solid waste is possible when the combustion chamber outlet temperature is above 850°C. The furnace is heated using waste oil, or if no waste oil is available by the burning of diesel oil. When this temperature is reached the lock on the solid waste inlet port is released allowing solid waste to be loaded into the incinerator hopper. Solid waste should be loaded a little at a time so that the exhaust gas temperature does not rise above 1,000°C.

Ash may be removed from the incinerator ash removal door after the incinerator has been shut down and has cooled below 50°C.

Note: Both the solid waste loading door and the ash removal door are interlocked on a temperature controlled interlock to prevent them being opened at too high a temperature.

Shipboard incineration of the following is prohibited:

- Annex I, II and III cargo residues to MARPOL 73/78 and related contaminated packaging.

- Polychlorinated biphenyl (PCB)

- Garbage as defined in Annex V to MARPOL 73/78 containing more than traces of heavy metals.

- Refined petroleum products containing halogen compounds.

Note: do not incinerate PVC polymer but dispose of it by landing it ashore.. PVC when burnt releases hydrogen chloride and will combine with free condensing moisture in the flue gases to form hydrochloric acid.

CAUTION: During the burning of sludge oil or solid waste the ash removal door must not be opened and the feeding of solid waste must only take place through the loading doors.

Procedure for the Operation of the Incinerator

The description below assumes that the incinerator system has been set up and tested using diesel oil and that the system is functioning correctly without leaks.

Waste Oil Incineration

a) Clean the waste oil pump strainer and drain water from the waste oil tank(s) using the sludge valve.

b) Heat the waste oil service tanks to 60-90ºC.

c) Open the waste oil supply valve to the incinerator and ensure that the return valve from the waste oil pump is operational. Open the waste oil tank outlet and return valves for the tank from which waste oil is to be taken.

d) Ensure that there is a supply of MDO in the MDO service tank and that the tank outlet valve is open.

e) Inspect the combustion chamber for foreign objects and ash or slag and remove these if necessary.

e) Check the combustion chamber air inlets are clear.

f) Clean the photocell.

g) Clean the ignitor electrodes.

h) Check the condition of the refractory.

i) Clean the diesel oil burner.

j) Clean the waste oil burner.

k) Supply atomizing air to the burner unit.

l) Close the ash door and loading door.

m) Open the exhaust dampers fully.

n) Turn the “DO” Substitution’ switch to the NOR position.

o) Turn the ‘Pilot Burner Assist’ switch to the NOR position. (If pilot burner assistance is needed to burn waste oil with a high water content this switch must be turned to the ASSIST position.)

p) Turn all manual operation switches to the AUTO position.

q) Turn the waste oil pressure and flow regulating valves to the fully open positions.

r) Turn the power switch to the ON position; the power lamp will illuminate.

s) Press the RESET pushbutton.

t) Press the AUTO START pushbutton. The induced draught fan will start and the waste oil pump will circulated waste oil. When the waste oil temperature at the burner reaches 60ºC it is possible for the burning of waste oil to commence. As the incinerator is in automatic mode the burning of waste oil will commence when the temperature of the oil at the burner reaches 60ºC (provided that the furnace temperature is satisfactory after the burning of diesel oil). When waste oil is burning regulated the flow of waste oil with the waste oil pressure regulating valve in order to obtain a combustion chamber outlet temperature of 900-950ºC. If the waste oil burner stops and starts frequently during waste oil burning throttle in the waste oil flow.

u) When the waste oil in the waste oil tank is all consumed the waste oil tank low level limit switch will be activated and the waste oil burner will be shut off. If the pilot burner assistance has been used the pilot burner will be extinguished at the same time. If it is necessary to stop the burning of waste oil before the tank is empty the AUTO STOP pushbutton is pressed. Prior to shutting down the incinerator diesel oil substitution is used to replace waste oil in the burner pipes with diesel oil (see below).

v) The incinerator will shut down and when the exhaust temperature reaches 50ºC the induced draught fan will stop.

If the other waste oil tank contains waste oil which needs to be burned the tanks may be changed over whilst the incinerator is burning waste oil.

Burning Solid Waste

The waste oil burner may be used as a combustion assist burner for the burning of solid waste; this reduces the MDO consumption. Solid waste may be burned when the exhaust gas temperature falls in the range 850-900ºC. The incinerator is prepared in the same way as for burning waste oil except that in item t) above the waste oil pressure regulating valve is adjust to maintain an exhaust temperature of 850-900ºC. When the exhaust temperature at the combustion chamber outlet reaches 850ºC the lock on the solid waste inlet port is released to permit the loading of solid waste.

Note: solid waste is loaded a little at a time into the loading port so that the heat capacity of the incinerator of 581KW, or 581kJ/s is not exceeded. Although most solid waste has a lower calorific value than waste oil, its combustion can exceed the kilojoule/second limit.

When solid waste has all been burned continue burning waste oil as above then shut down the incinerator when the waste oil has all been burned.

The ash pusher is used to push ash towards the ash removal door in order to facilitate removal of the ash and prevent large amounts of ash building up in the furnace.

Diesel Oil Substitution

After the burning of waste oil is complete diesel oil is substituted at the burner in order to prevent waste oil from blocking the pipes of the incinerator.

The MDO supply valve is opened and the waste oil supply valve from the waste oil tank is closed. The ‘DO Substitution’ switch is turned to the ON position and the burner is operated with MDO being supplied. Operation continues for a few minutes until all waste oil is removed from the burner unit.

Emergency Stops

The incinerator may be stopped in an emergency by turning the main switch on the control panel to the OFF position. The incinerator waste oil quick-closing valves and the incinerator DO service tank quick-closing valve may be tripped remotely.

In the event of a loss of electrical power during a blackout when the incinerator is running it is important to start the flue gas fan as soon as possible upon restoration of electrical power in order to cool the combustion furnace effectively.

Incineration Of Solid Waste (trash, rags, waste oil filter cartridges etc.)

a) Control the size of charge depending on the type of material.

b) Remove ash before running.

c) For simultaneous burning of solid and oily wastes, reduce the rate of waste oil burning to avoid an overheat trip.

d) Warm up the furnace as described previously before charging with solid waste.

e) Cut large solid items into smaller pieces and divide them into charging lots depending upon combustibility.

f) Avoid overcharging the incinerator with high calorific materials such as plastics and oily material.

g) To avoid damage to the furnace and burner, ensure that the fans are running while solid waste is burning.

CAUTION: Oily rags etc., must be loaded in small quantities only (approximately 1.5kg per loading) and must not be present in the combustion chamber unless the induced draught fan is running.

WARNING: Do not attempt to burn explosives or aerosol spray cans in the incinerator as rapid expansion of gasses could cause the designed internal incinerator combustion chamber to exceed the designed limit of 6kPa.