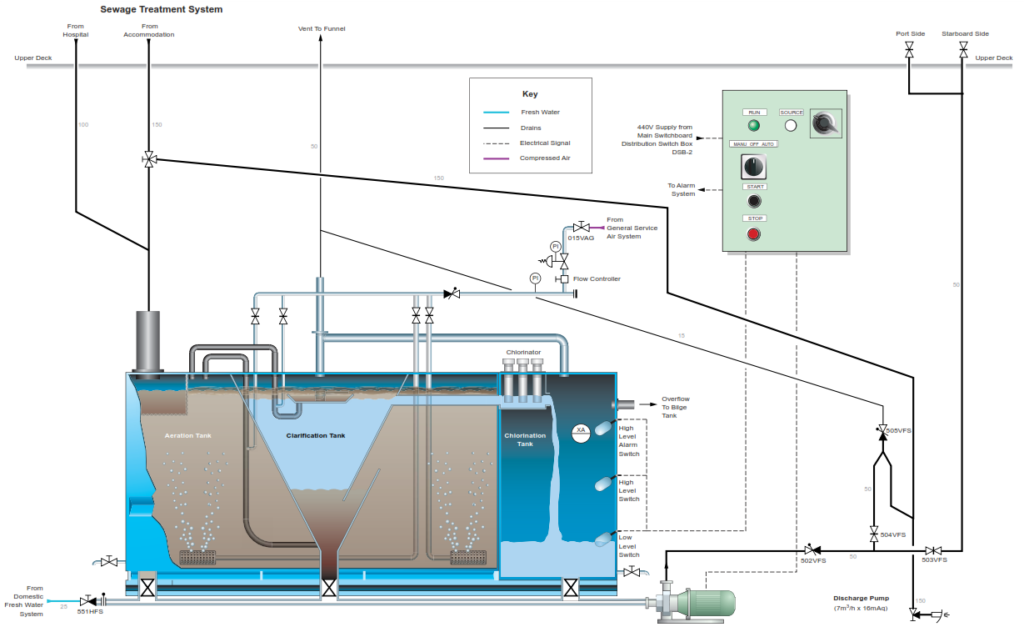

The sewage treatment plant treats all sewage in a three tank unit using activated sludge and extended aeration.

Sewage Treatment Plant

The sewage treatment plant consists of three separate tanks through which the sewage passes and during that passage through the tanks bacteria effectively breaks down the raw sewage so that the discharge into the final tank is clean water. This cleaned water is treated with chlorine to destroy harmful pathogens before it is pumped overboard. Because the sewage is digested by bacteria it is essential that there is a steady supply of sewage to the tank in order to ensure that the bacteria can thrive.

Note: The use of disinfecting chemicals for cleaning lavatory pans, or the disposal of such chemicals in lavatory pans, will kill the bacteria in the sewage treatment plant and such practices are forbidden.

A three-way valve enables raw sewage from the accommodation to be directed to the sewage treatment plant or overboard if required. The hospital sewage discharge goes directly to the sewage treatment plant. Although the sewage treatment plant discharge pump is normally set for overboard discharge, effluent from the sewage treatment plant may also be discharged to the shore connections on the port and starboard sides of the ship.

Aeration Tank

The sewage in this tank is from the lavatory pans and urinals in the accommodation spaces; flow from the accommodation is by gravity.

The incoming effluent material mixes with the activated sludge already present in this tank. The bacterial action breaks down the sewage producing carbon dioxide, water and new bacteria. The gases produced are vented to atmosphere. The ship’s working air system supplies air to the tank, which provides the oxygen the aerobic organisms require for digesting the raw sewage and it also assists in mixing the incoming sewage with the water, sewage sludge and bacteria already present in the tank. The aeration tank is supplied with air from the blower and it also has an air lift. This is basically a vertical pipe through which air is bubbled and this acts to draw effluent from the bottom of the aeration tank and discharge it to the settling tank. The rate of flow through the aeration tank is designed to be as slow as possible to enable maximum bacterial effect. The aeration period is about 12 hours after which the effluent is pumped to the clarification compartment by means of the transfer air lift.

Clarification Tank

The effluent passes into this tank and settles out. The water passes into the chlorine contact tank, whilst the remaining sludge, containing the active bacteria, returns to the aeration tank for further processing. A surface skimmer in the tank removes floating sludge and debris from the surface and returns it to the activation tank.

Chlorine Contact Tank

Water from the clarification tank is brought into contact with sterilizing tablets containing the required amount of chlorine and is sterilized. The disinfecting tubes are filled with chlorine tablets (the amount and number of tubes in use depending upon the sewage plant throughput), and the water is sterilized when it comes into contact with the tablets and dissolves the chlorine in the tablets. After flowing through the disinfecting tubes the water passes to the discharge chamber which is fitted with float switches controlling the start and stop of the discharge pump.

CAUTION: Discharge overboard should not take place within 12 nautical miles of the coast. Raw sewage may only be pumped to sea in waters where such discharge is permitted and permission from the bridge must be obtained before the discharge takes place.

Note: Rules governing the discharge of raw sewage must be complied with at all times and the discharge of raw sewage overboard must only be contemplated should the sewage plant not be serviceable. The bacterial action requires a regular supply of raw sewage and the discharge of raw sewage overboard can impair effective bacterial action.

The sewage treatment plant works automatically once the control switch is set to the ON position and the selector switch for the discharge pump is set to the AUTO position. Periodic attention is required and the unit must be monitored for correct operation.

The plant requires a throughput of raw sewage in order to keep the bacteria active. If there is no sewage flow for a prolonged period the bacteria will become inactive and operation of the plant subsequently impaired. When raw sewage supply is resumed it may take some days before full bacterial activity is restored and this can result in imperfect treatment and the discharged of untreated sewage.

Disinfectant material must never be used for cleaning lavatory pans or urinals as this kills the bacteria which are essential for satisfactory operation of the sewage treatment plant.

The sewage treatment plant discharge pump normally takes suction from the chlorine contact tank but valves on the other two tanks allow those tanks to be pumped out if necessary.

Procedure for Operating the Sewage Treatment Plant

a) Set the system valves as in the following tables.

| Position | Description |

| Open | Three-way sewage valve from accommodation (set for sewage treatment plant inlet) |

| Closed | Fresh water inlet to sewage treatment plant |

| Open | Chlorination tank discharge valve |

| Closed | Aeration tank discharge valve |

| Closed | Clarification tank discharge valve |

| Open | Pump discharge valve to overboard discharge line |

| Closed | Pump discharge valve to shore discharge line |

| Closed | Port shore discharge valve |

| Closed | Starboard shore discharge line |

| Open | Air supply valve from service air system |

| Open | Air supply valves to tank aeration and air lift outlets |

| Closed | Chlorination tank sampling valve |

b) The sewage treatment plant should be initially filled with water and activated sludge added if it has been emptied for any reason or when commissioning the plant for the first time. This will not be required when the unit has been operating previously but the description is included for completeness.

c) Turn the sewage treatment plant main switch to the ON position.

d) Ensure that the ship’s service air system is operating and that compressed air is being supplied to the sewage treatment plant and is regulated to 0.5MPa Check that the aeration and air lift systems are operating.

e) Turn the overboard discharge pump switch to the AUTO position.

f) Check that the discharge pump has the correct rotation.

g) Ensure that there are sufficient chlorine tablets in the chlorination tank.

Note: The number of tablets and number of tubes in use may need to be adjusted through experience, depending upon the throughput of the sewage plant.

h) Check that the discharge pump is operating correctly in response to the float switches in the chlorination tank.

i) Check that ample air is being supplied and that sludge is being returned to the activation tank from the clarification tank. This can be checked by looking at the transparent hose in the return line.

j) The sewage treatment plant is now operating.

k) The discharge pump will only operate when the chlorination tank is full enough to activate the high level float switch.

CAUTION: Tanks may only be pumped to sea in waters where such discharge is permitted and permission from the bridge must be obtained before the discharge takes place.

The chlorine level in the discharge effluent must be checked using the chlorine test kit. A sample of the effluent must be obtained from the chlorination tank using the sample valve . If the residual chlorine content is less than 1ppm additional chlorination tablets must be used or additional tablet feed tubes must be brought into use if they are not already being used.

WARNING: Care must be taken in the storage and handling of the Sodium Hypochlorite tablets (Chlorine tablets). They must never be in contact with bare skin and must not be exposed to high temperature or fire. Chlorine tablets must never be exposed to damp conditions and must not be allowed to get wet in storage.

Sewage Discharge Ashore

When in confined waters where the overboard discharge of treated sewage is prohibited it is necessary to discharge the treated effluent ashore. Approval must be obtained from the harbour authorities and the reception facility must be provided which can accommodate the amount of treated sewage to be discharged. The blank is removed from the port or starboard discharge pipe and the hose to the reception facility connected. The overboard discharge valve is closed and the discharge valve to the shore connection is opened.

Treated effluent is discharged by operating the sewage treatment plant discharge pump.

Maintenance

Daily Checks

Check that the sludge is being returned to the activation chamber from the settling chamber, and that the discharge pump and blower are working. Check that the sterilizing unit is functioning correctly and replenish as necessary.

Check the operation of the air lift and the air diffusers through the compartment portholes. Check that the air supply pressure is correct at the air inlet to the sewage treatment plant.

Weekly Checks

Check the residual chlorine level; this should always be between 1ppm and 5ppm.

Monthly Checks

Check that air flows are correct and that compartment vents are clear. Clean the blower suction strainer.

Check that the chlorinator unit is clear and that the float switches are operating correctly.