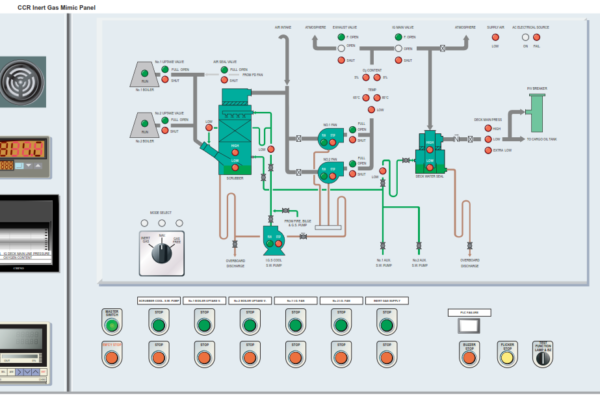

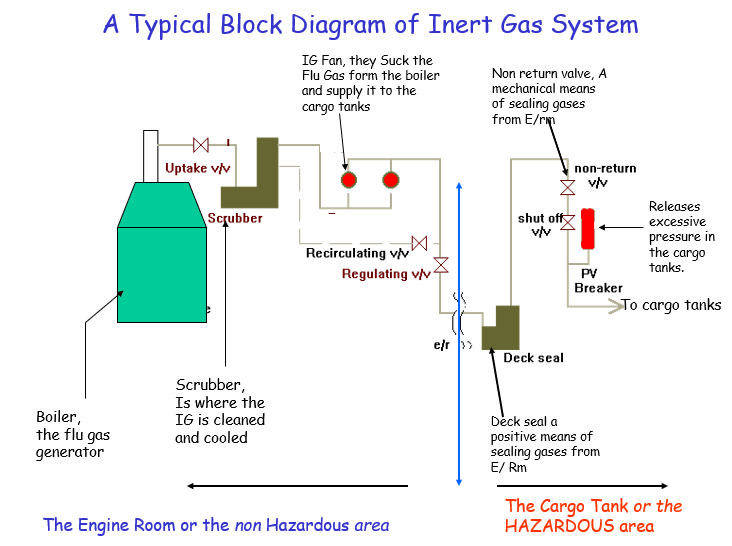

Inert Gas System

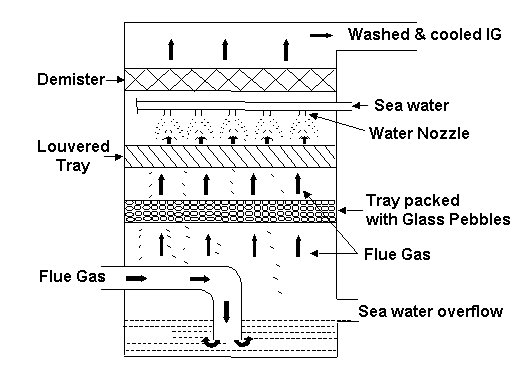

The inert gas system (IGS) consists of a main inert gas plant, using boiler flue gas to provide a gas explosion protection system, i.e. a low O2 content in the cargo oil tanks and slop tanks. This is achieved by maintaining a slight overpressure in