What is Inert Gas ?

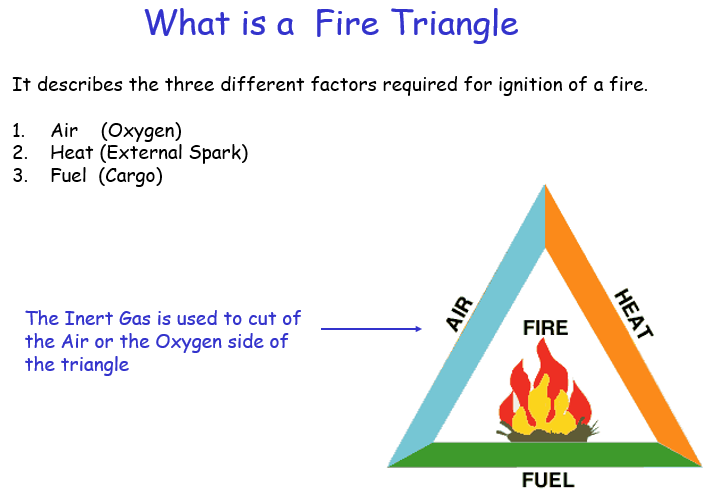

It is a gas which contains insufficient Oxygen to support combustion.

Keeping tanks inerted means cutting one side of the fire triangle and hence avoiding any chances or Fire or Explosion.

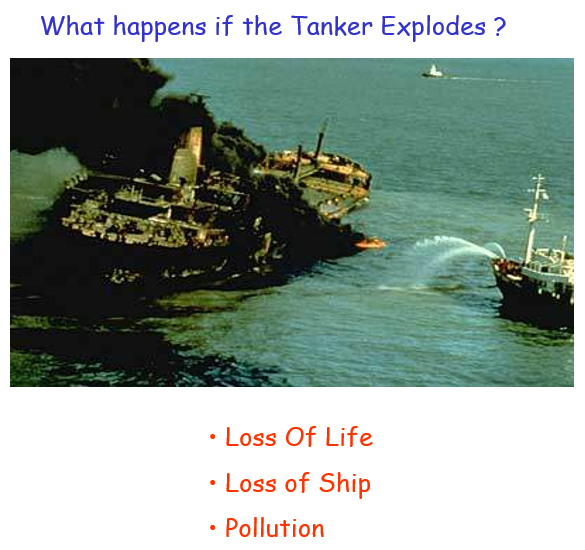

Why do we need Inert Gas ?

An Oil Tanker carries petrolieum cargo, which give out flammable vapors .

In the absence of Inert gas, any source of ignition will cause the atmosphere within a tank on the tanker to explode.

What is the percentage of oxygen required to sustain combustion ?

More than 11 %

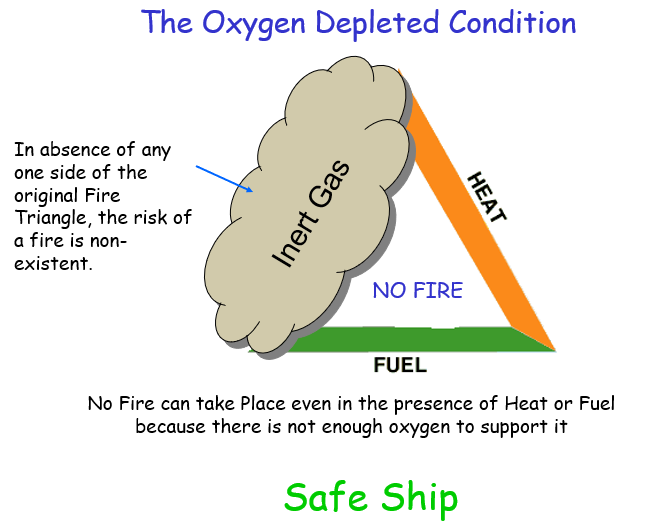

What percentage of oxygen are we required to maintain in the cargo tanks ?

By law less than 8 %. Some ports require a vessel to maintain less than 5 %.

A Cargo tank is considered “Inerted” when the oxygen content in the tank is less than 8 % by volume

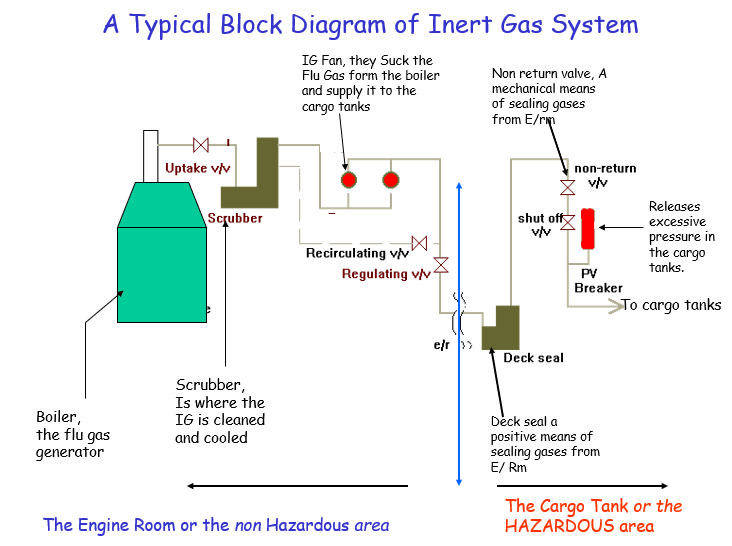

How can we produce such Inert Gas (oxygen depleted gas) on board a ship ?

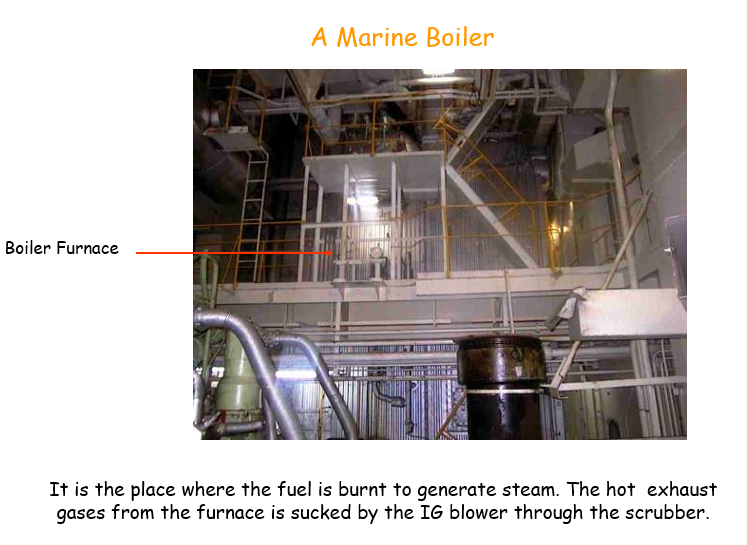

From the Exhaust Gases (Flue gas) of a boiler. The combustion of the Boiler can be controlled to reduce the oxygen to less than 5 % in its exhaust.

Why can’t we use the Exhaust from the Ships Main Engine or Auxiliary Engine?

Engines are designed to work with higher percentage of oxygen for better combustion and efficiency.These exhaust gases are rich in oxygen and much above 11 %. Hence not suitable for use as IG

How much does it cost us to make Inert Gas on board ?

It is almost free of charge because

1.Inert gas is mainly used during the discharge of the vessel.

2.The Boiler is anyway running during the discharge of cargo to power the turbines of the cargo oil pumps.

Hence just by treating the exhaust gas of this boiler would generate the Inert Gas

When Is Inert Gas Plant Used

- During Discharging to replace the volume of the Liquid in the tank.

- For Purging, so as to replace the atmosphere in the tank.

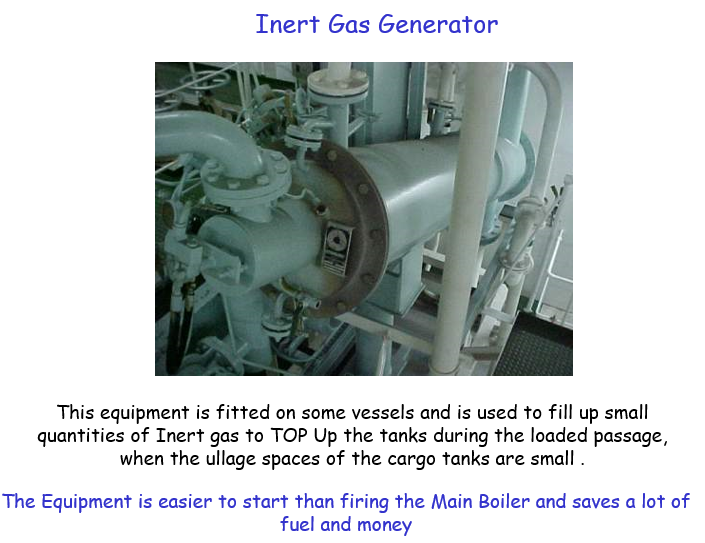

- To Top up cargo tanks in loaded voyages.

Can the Exhaust gases of the boiler sent straight to the cargo tanks ?

NO,

Due to the following reasons

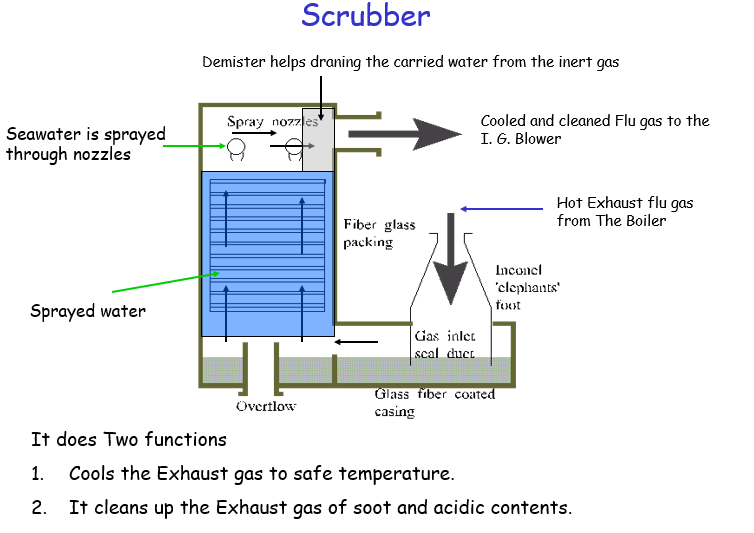

- The Exhaust gases of the boiler are very hot and dirty and requires treatment prior they are sent to the cargo tanks.

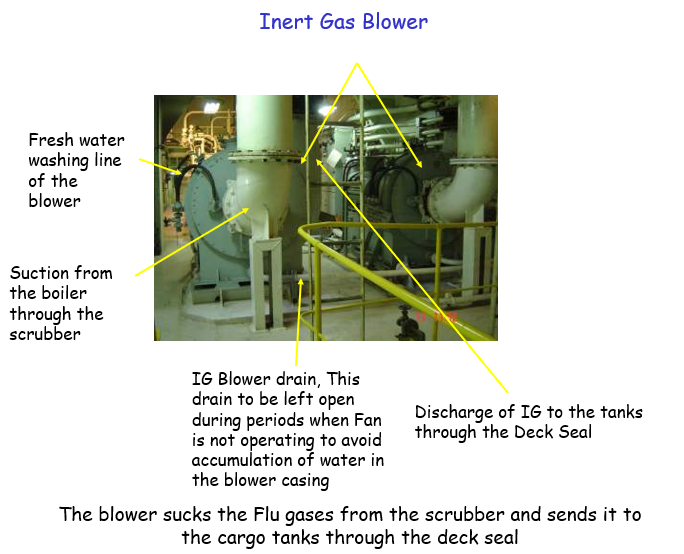

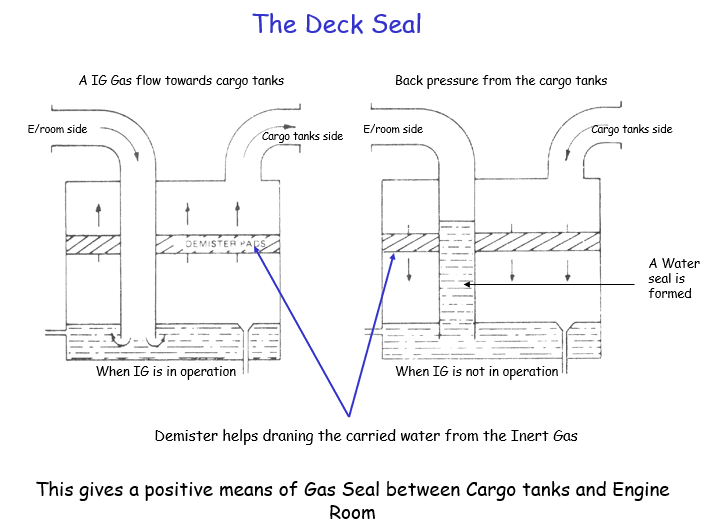

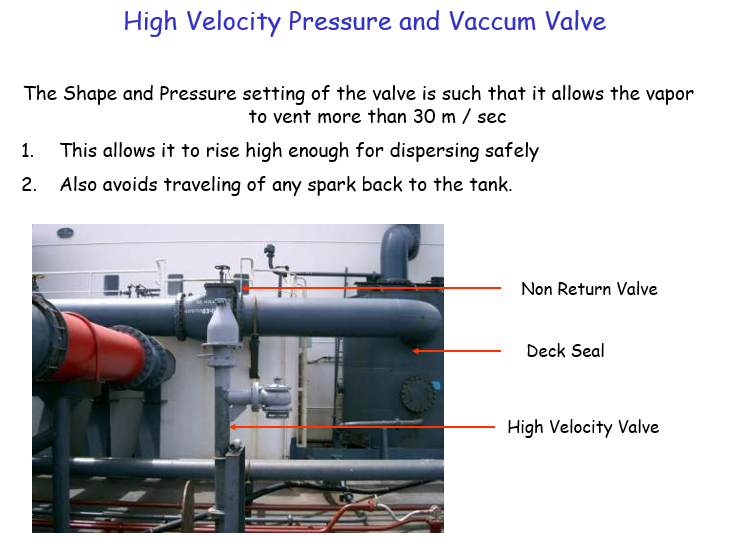

- Any connection between the Non hazardous area (Engine room) and the Hazardous area(Cargo Tanks) calls for safety barriers between the two areas so as to prevent back flow of flammable gases to the boiler from the cargo tanks.

Block Diagram of Inert Gas System

Various components of IGS