On a oil tanker the cargo oil tank atmosphere changes as per various operations the ship is performing.

These includes the Key Cargo Operations such as:

- Discharging

- Tank Cleaning

- Purging

- Gas Freeing

- Inerting

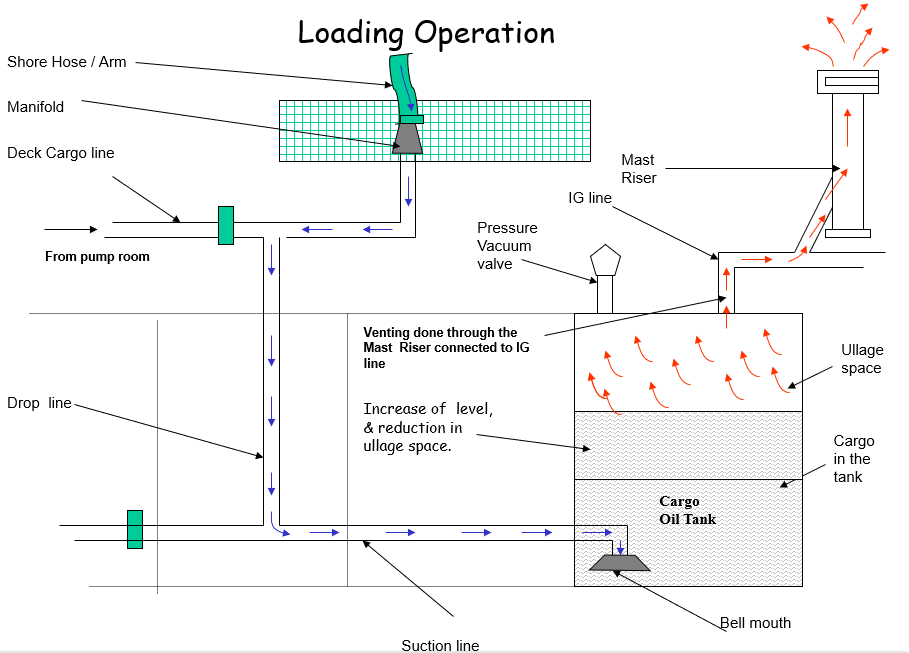

- Loading

When performing these key cargo operations safely, The most important concern is to have a safe & controlled cargo tank atmosphere.

Tankers fitted with an inert gas system should maintain their cargo tanks in a non-flammable condition at all times.

It follows that:

- Tanks are kept inerted when they contain cargo /cargo residue

- The atmosphere within the tank should make the transition from inert condition to gas-free condition without passing through flammable condition.

- In practice before any tank is gas freed, it would be purged with inert gas until the hydrocarbon content of the tank atmosphere is below the critical dilution line.

- When a ship is in a gas-free condition before arrival at a loading port, tanks should be re-inerted prior to loading.

Venting system for a cargo oil tank

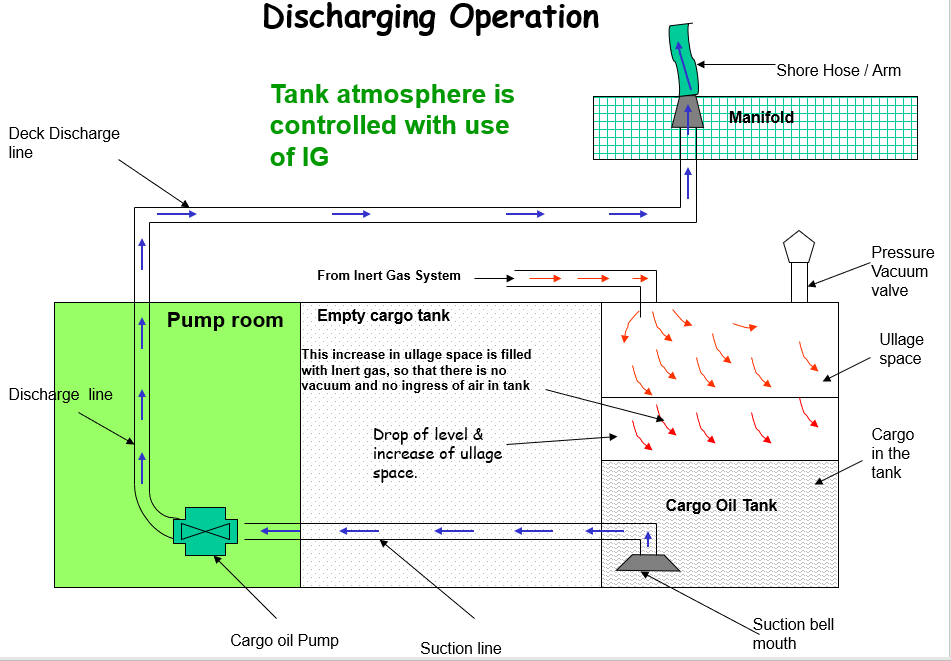

Discharging Operation

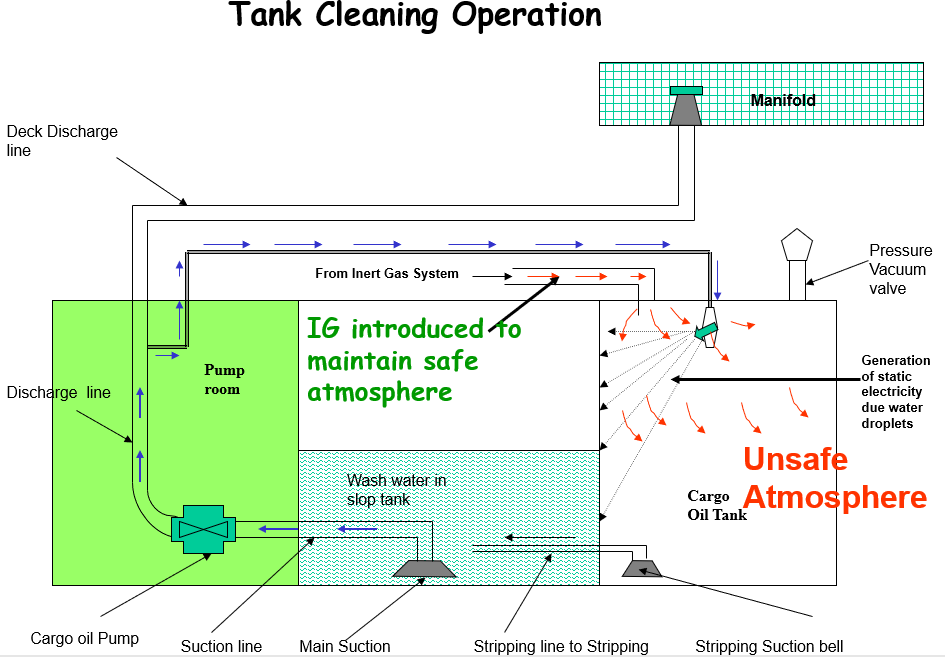

Tank Cleaning Operations

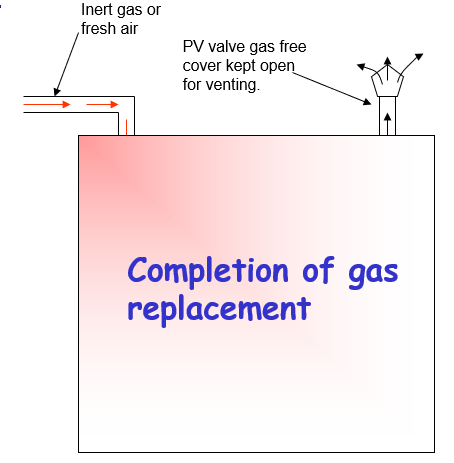

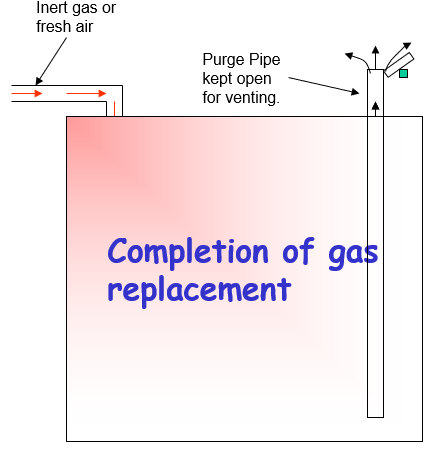

After tank cleaning there are 3 operations which involve replacement of gas in cargo tanks.

Namely:

- Purging (For reducing the hydrocarbon /H2S content )

- Gas-freeing (For man-entry).

- Inerting (For preparation before arrival load Port)

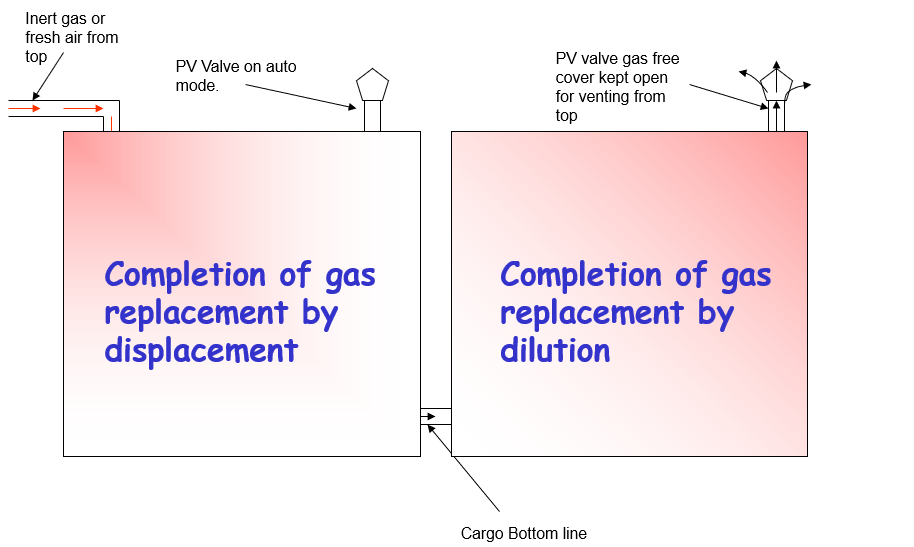

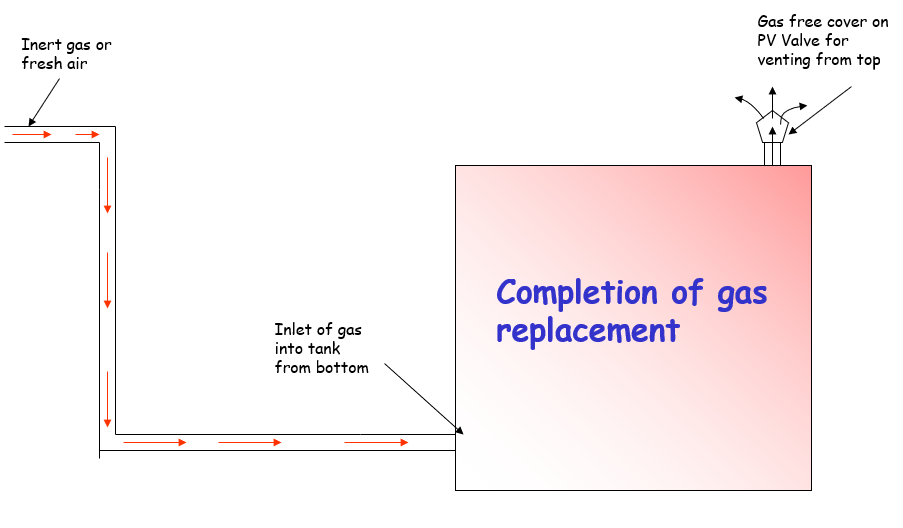

And there are 2 principal means of Gas Replacement for above operations, these are :

- Dilution , which is a mixing process

- Displacement, which is layering process

Dilution Method

Dilution theory assumes Incoming inert gas / air, mixes with the original gas mixture in tank to form a homogenous mixture throughout the tank,

In result concentration of original gas decreases gradually.

Important!!!

For complete replacement the entry velocity of incoming gas should be high enough for the jet to reach the bottom of tank.

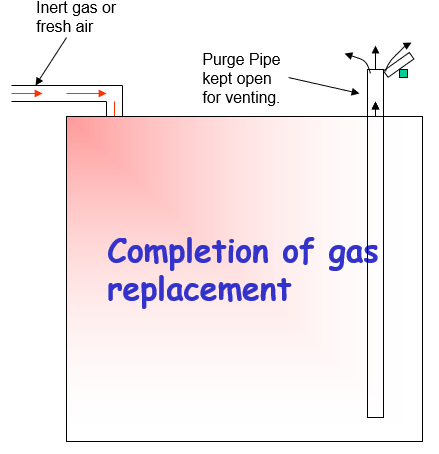

Displacement Method

For ideal replacement a stable horizontal interface should be formed between the lighter gas entering at the top of tank and heavier gas being displayed from the bottom of tank through some suitable pipping arrangement.

In result the tank atmosphere is changed gradually.

Important!!!

For complete replacement a relatively low entry velocity of gas is required. In practice more than one volume change is necessary.

Several arrangements are put in use on board tanker, when using dilution or displacement method.

One feature which is common to all is that the inlet and outlet points should be so located that efficient gas replacement can take place through out the tank.

There are three principal arrangement:

Displacement /Dilution method-using bottom cargo lines from one tank to other tank

Dilution method-using bottom cargo lines from IG line to tank

Increase of tank pressure,as loading is done in closed ullaging system to control the safe atmosphere in tank.