Deficiencies

During an inspection the PSC inspector may identify one or more deficiencies and include these in the PSC inspection report. Each deficiency has a unique code.

In the FORM B, it is also mentioned when the deficiency should be rectified. With all deficiencies, the applicable convention reference should be included.

With the deficiency there will also be an “action taken” specified. The list below contains the most frequently used “action taken” code:

Rectified (code 10)

Used for a deficiency which has been rectified and verified by a PSCO

To be rectified at next port (code 15)

Used for a deficiency which cannot be rectified before departure but which the PSCO requires the rectification at the next port

This action requires that the deficiency is rectified at the next port. It is possible that the repair work or delivery of equipment may take place during the ship’s stay in that port.

To be rectified within 14 days (code 16)

Used for a deficiency which, in the PSCO’s professional judgement, is not serious enough to require urgent rectification or verification by a PSCO before departure.

This action taken sets a maximum limit of 14 days but it is left to the master’s responsibility to rectify the deficiency as soon as necessary and reasonable within that period.

To be rectified before departure (code 17)

Used for a deficiency which:

should be rectified before the ship sails but is not serious enough to warrant detention, or/and can reasonably be rectified before the ship sails.

If the ship is not detained it is left to the master’s responsibility to rectify the deficiency before departure. No verification by a PSCO is required (at that port call).

If a deficiency which is to be rectified before departure is verified by a PSCO as rectified before the ship departs it should be recorded as rectified.

(code 19) Safety management audit by the Administration is required before departure of the ship

Safety management audit by the Administration is required before departure of the ship. Deficiency(s) marked ISM is (are) objective evidence of a serious failure, or lack of effectiveness, of implementation of the ISM Code.

Corrective action taken on the ISM system by the Company is required within 3 months (code 21)

Corrective action taken on the ISM system by the Company is required within 3 months. Deficiency(s) marked ISM is (are) objective evidence of a failure, or lack of effectiveness, of the implementation of the ISM Code. The ship will be eligible for re-inspection after 3 months from the final date of the report.

Competent Security Authority informed (code 26)

Used only for a deficiency of the Security code series where the competent security authority of the PSCO’s State is informed that clear grounds have been found in accordance with the PSCCInstruction Guidelines on Security.

Grounds for detention (code 30)

Used for a deficiency that is serious enough that it should be rectified before departure and reviewed by the PSCO before the ship may continue its voyage.

Used for each detainable deficiency that is determined, in accordance with a PSC Instruction on Criteria for Responsibility Assessment of Recognized Organizations (R/O) should be related to the Recognized Organization that issued or endorsed the statutory certificates related to the detainable deficiency.

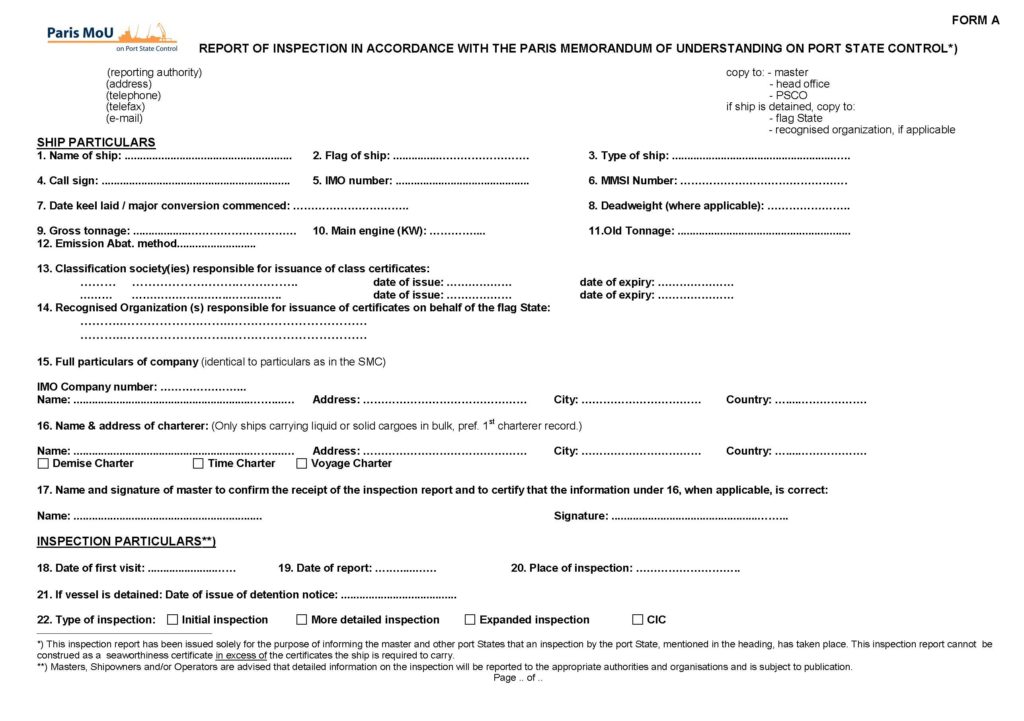

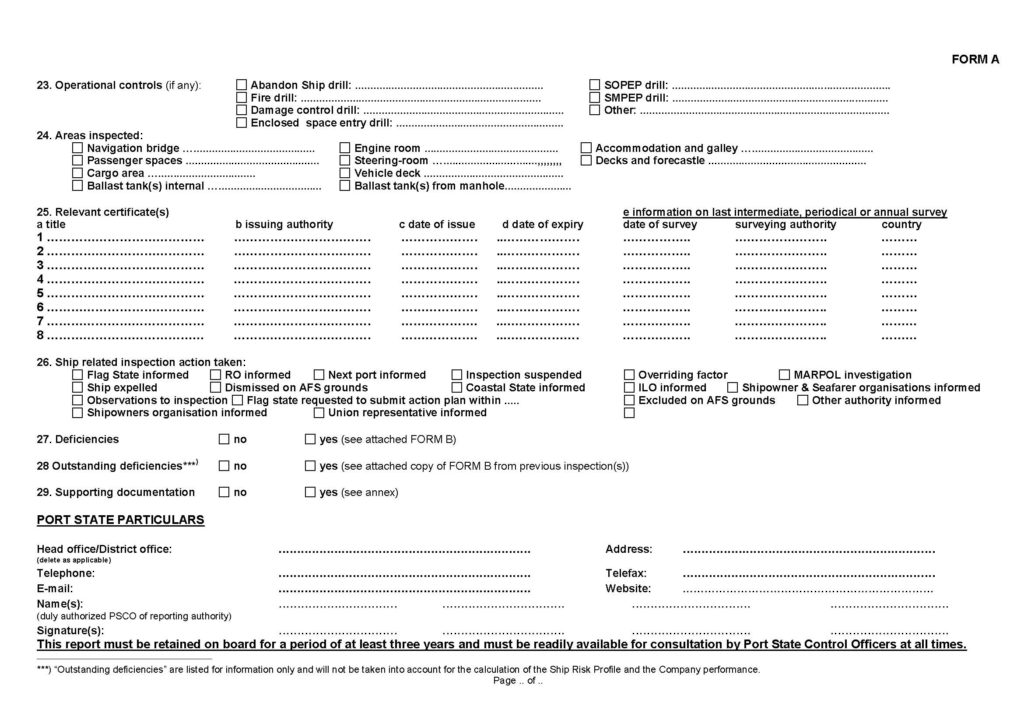

PSC Reporting FORM A

Will be issued to all ships which has been inspected by PSC inspector.

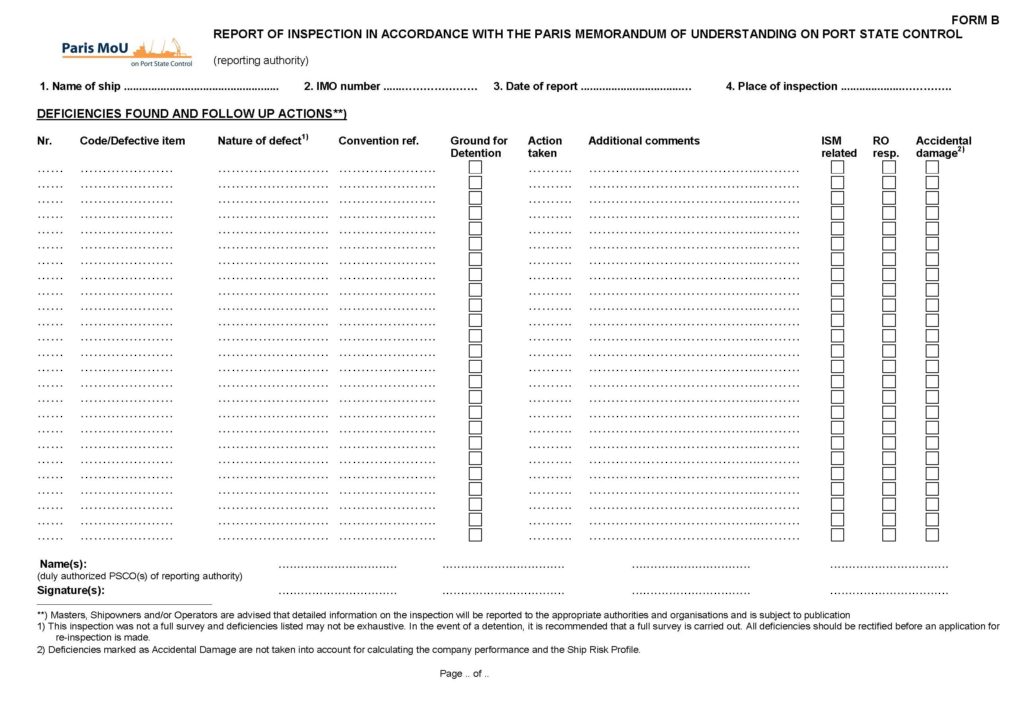

PSC Reporting FORM B

This form will be accompanied with FORM A when the vessel has been inspected and some observations has been found, deficiency alongwith deficiency code and action code will be mentioned by PSC inspector.

Deficiency Codes

Each deficiency have a unique code to easily identify the items related to, following below are some examples:-

011 – Certificates & Documentation – Ship Certificate

01101

Cargo ship safety equipment (including exemption)

01102

Cargo ship safety construction (including exempt.)

012 – Certificates & Documentation – Crew Certificate

01201

Certificates for master and officers

01202

Certificate for rating for watchkeeping

013 – Certificates and Documentation – Document

01302

SAR co-operation plan for pass.ships on fixed trade

01303

Unattended machinery spaces (UMS) evidence

02 – Structural condition

02101

Closing devices/watertight doors

02102

Damage control plan

03 – Water/Weathertight condition

03101

Overloading

03102

Freeboard marks

04 – Emergency Systems

04101

Public address system

04102

Emergency fire pump and its pipes

05 – Radio communication

05101

Distress messages: obligations and procedures

05102

Functional requirements

06 – Cargo operations including equipment

06101

Cargo securing manual

06102

Grain

07 – Fire safety

07102

Inert gas system

07103

Division – decks, bulkheads and penetrations

08 – Alarms

08101

General alarm

08102

Emergency signal

09 – Working and Living Conditions

091 – Working and Living Conditions – Living conditions

09101

Minimum age

09102

Dirty, parasites

092 – Working and Living Conditions – Working Conditions

09201

Ventilation (Working spaces)

09202

Heating

10 – Safety of Navigation

10101

Pilot ladders and hoist/pilot transfer arrangements

10102

Type approval equipment

11 – Life saving appliances

11101

Lifeboats

11102

Lifeboat inventory

12 – Dangerous Goods

12101

Stowage/segregation/packaging of dangerous goods

12102

Dangerous liquid chemicals in bulk

13 – Propulsion and auxiliary machinery

13101

Propulsion main engine

13102

Auxiliary engine

14 – Pollution Prevention

141 – Pollution Prevention – MARPOL Annex I

14101

Control of discharge of oil

14102

Retention of oil on board

142 – Pollution Prevention – MARPOL Annex II

14201

Efficient stripping

14202

Residue discharge systems

143 – Pollution Prevention – MARPOL Annex III

14301

Packaging

14302

Marking and labelling

144 – Pollution Prevention – MARPOL Annex IV

14402

Sewage treatment plan

14403

Sewage comminuting and disinfecting system

145 – Pollution Prevention – MARPOL Annex V

14501

Garbage

14502

Placards

146 – Pollution Prevention – MARPOL Annex VI

14601

Technical Files and if applicable, monitoring manual

14602

Record book engine parameters

147 – Pollution Prevention – Anti Fouling

14701

AFS supporting documentation

14702

Logbook entries referring AFS

148 – Pollution Prevention – Ballast Water

14801

Ballast Water Management Plan

14802

Ballast Water Record Book

15 – ISM

15150

ISM

16 – ISPS

16101

Security related defects

16102

Ship security alert system

18 – MLC, 2006

181 – Minimum requirements to work on a ship

18101

Minimum age

18102

Night working

182 – Conditions of employment

18201

Fitness for duty – work and rest hours

18202

Legal documentation on work and rest hours

183 – Accommodation, recreational facilities, food and catering

18301

Noise, vibration and other ambient factors

18302

Sanitary Facilities

184 – Health protection, medical care, social security

18401

Medical Equipment, medical chest, medical guide

18402

Access to on shore medical doctor or dentist

99 – Other

99101

Other safety in general

99102

Other (SOLAS operational)

99103

Other (MARPOL operational)

Appeal procedure

National appeal

When deficiencies are found which render the ship unfit to proceed or that poses an unreasonable risk to the environment, the ship will be detained. The PSCO will issue a notice of detention to the master.

The PSCO will inform the master that the ship’s owner/operator has the right of appeal.

Detention review procedure

In case an owner or operator declines to use the official National appeal procedure but still wishes to complain about a detention decision, such a complaint should be sent to the flag State or the Recognized Organization, which issued the statutory Certificates on behalf of the flag State.

The flag State or R.O. may then ask the port State to reconsider its decision to detain the ship.

If the flag State or the R.O. disagrees with the outcome of the investigation as mentioned above, a request for review may be sent to the MOU Secretariat.

Concentrated Inspection Campaigns (CIC)

Regional PSC MOU members will agree to carry out concentrated inspection campaigns from time to time for periods of usually three or four months. These campaigns are often announced beforehand through press releases and other means and generally focus on certain aspects of ship safety. Past inspection campaigns have focused on such areas as follows:

- MLC, 2006

- Structural Safety and Load Lines

- Cargo Securing Arrangements

- Tanker Damage Stability

- Crew Familiarization for Enclosed Space Entry

- Harmful Substances Carried in Packaged Form

- STCW Hours of Rest

- Lifeboat Launching Arrangements

- Propulsion and Auxiliary Machinery

- Safety of Navigation

- Fire Safety Systems

- ISM Code