Below guidelines should be used by the vessel’s staff prior to arrival into port. The categories and items identified below are items that have been identified as top Port State detention items on board vessels.

Below guidelines should be used in conjunction with the normal pre-port arrival and departure checks required by international regulations and in conjunction with on board routine maintenance programs. If any of the items identified in the below guidelines are not in good working condition, the crew should take appropriate steps to remedy the situation prior to arrival into port.

Below guidelines is organized according to major categories as well as items identified by Port State Control (PSC) as areas of concern. For each major category the top items have been identified for your easy reference.

Port State Control officers typically begin inspections in the Master’s office to confirm that the vessel and crew have all of the appropriate certificates and documents in accordance with applicable international and local requirements.

The following items should be verified as a minimum prior to the vessel entering port:

MASTER OFFICE

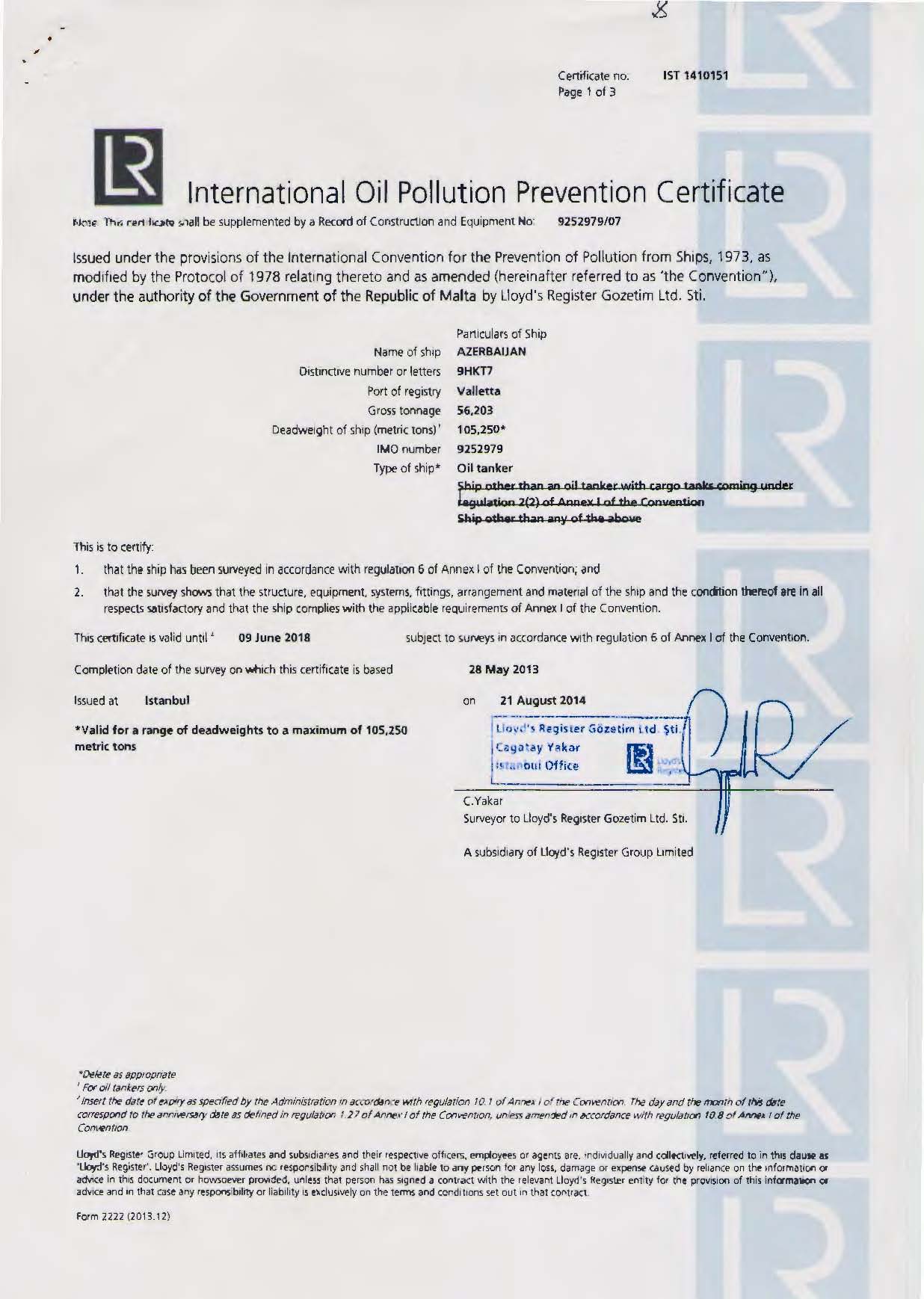

CERTIFICATES

- Certificates and documents are available on board, current and valid, and properly endorsed.

- The vessel’s Master reviews the information to confirm that the agent has returned the original certificates.

- Servicing certificates for firefighting and lifesaving equipment are in date and available.

- Special attention should be paid to dates, capacities, and required supplements.

STANDARDS OF TRAINING, CERTIFICATION AND WATCHKEEPING (STCW)

- The vessel’s crew members are adequately trained and have the appropriate training certification. Many flag Administrations may require certificates to be issued by the vessel’s flag State.

ISM AND ISPS CODES

- The vessel’s Master has a firm knowledge of the vessel’s Safety Management System as well as the International Ship and Port Facility Security (ISPS) Code.

- Proper on-board maintenance and drills are carried out and documented in the vessel’s log book as required by the ISM and ISPS Codes

ILO MARITIME LABOUR CONVENTION

- Master is familiar with the national requirements and company’s measures ensuring compliance with the requirements of the Convention relative to seafarers’ working and living conditions on board.

- Periodic inspections are carried out and documented for accommodation, food and drinking water, all spaces and equipment used for storage and handling of food, including galley areas.

MANUALS

Ship specific manuals and booklets are on board and up to date as applicable including:

- Life Saving Appliances and Fire Safety Training manuals

- Trim and stability booklet

- Loading manual

- Cargo securing manual

- Survey planning document (including enhanced survey report files) – required by ESP oil tankers, bulk carriers and chemical carriers

- Shipboard Oil Pollution Emergency Plan (SOPEP) including updated contact list Shipboard Marine Pollution Emergency Plan (SMPEP)

- Grain loading manual

- Damage control plan

- Loading instrument book

- Coating technical file – required for Performance Standard for Protective Coatings (PSPC)

- Emergency towing procedure

- Garbage and Oil Record Book

- Applicable maintenance manuals.

- Ballast Water Management Plan

BRIDGE

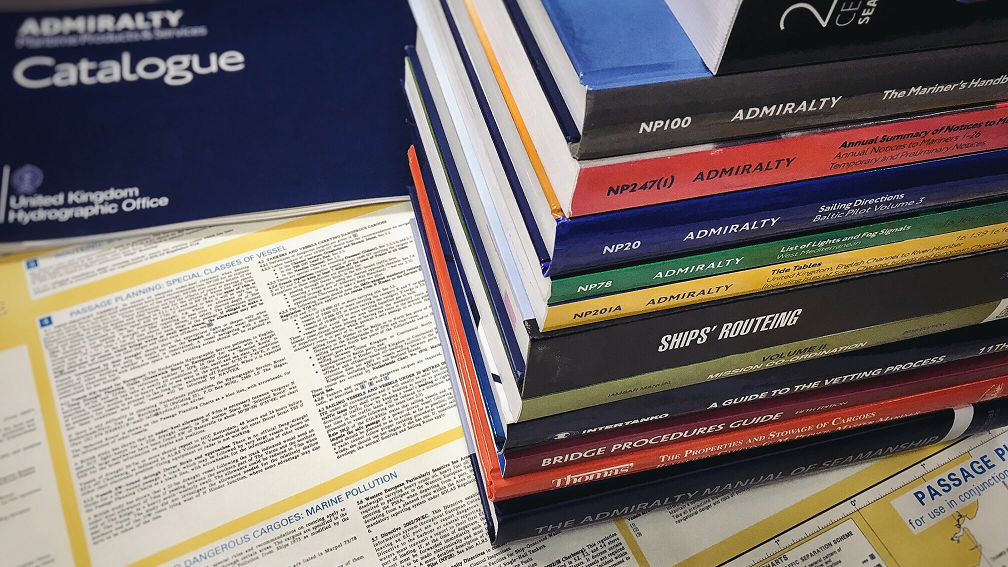

NAUTICAL PUBLICATIONS

- The latest publications are on board for ready reference such as IMO publications and flag Administration regulations.

CHARTS

- Charts, including tide tables, are up to date.

- The Notice to Mariners is properly logged.

- Electronic charts display the information systems.

PASSAGE PLANS

- Voyage passage plans are correctly documented.

LIGHTS, SHAPES AND SOUND SIGNALS

- The list of lights, international code of signals and illustrated table of lifesaving signals is legible and the signaling lamp is in good working condition and has been tested on both emergency power supply and battery power.

- Lights are installed in correct location based on COLREG 1972 (e.g. Stern Lantern, Mast Head Lantern, etc.).

- Port and Starboard side lights screens are painted matte black.

MAGNETIC AND GYRO COMPASSES

- The standard magnetic compass is adjusted for proper working condition, and the deviation card has been updated.

- No excessive deviation errors.

- The standard magnetic compass is free of air bubbles.

- The lifeboat/rescue boat magnetic compass is in good working order.

- The gyro compass is operational, and the error book is maintained.

GMDSS, EPIRB AND AIS

- Radio equipment is in good working order and is serviced and tested by a recognized radio technician.

- EPIRB is in proper working condition, programmed correctly and the battery expiration date is displayed within the window.

- The vessel’s automatic identification system (AIS) is properly programmed and operational.

- VDR annual performance test certificate is on board.

- LRIT is in working condition, and the test report is available.

RADAR TRANSPONDER

- The radar transponder is located in the proper location, operationally tested and the expiration date of batteries is confirmed.

RADARS, ECHO SOUNDER AND ECDIS

- Radars and echo sounder are in proper working condition.

- ECDIS audible alarms are fully functional.

BRIDGE NAVIGATIONAL WATCH ALARM SYSTEM (BNWAS)

- BNWAS to be demonstrated that system is protected by security pass code (should be under control of Master).

DOCUMENTATION

- Service records for life raft and fire extinguishing equipment.

- Ship records from the Master’s Log, primary and secondary steering gear testing, remote steering control, steering positions on the bridge, rudder angle indicator, steering gear failure alarms, control communications and control alarms, proper functioning of the emergency diesel generator, main propulsion ahead and astern testing.

THE BATTERY ROOM

- Room is to be inspected for cleanliness and proper ventilation.

- Battery room equipment is present and in good condition (gloves, eye protection, hydrometer, etc.).

PYROTECHNICS

- Dates on flares are not expired and required amount are to be on board.

ACCOMMODATION

FIRE DAMPERS AND DOORS

- The fire dampers are in good working condition, functionally tested and recently examined internally and externally.

- Damper flaps are structurally sound with no edge wastage.

- The external ventilation trunk is marked to show damper flap position – OPEN or CLOSE.

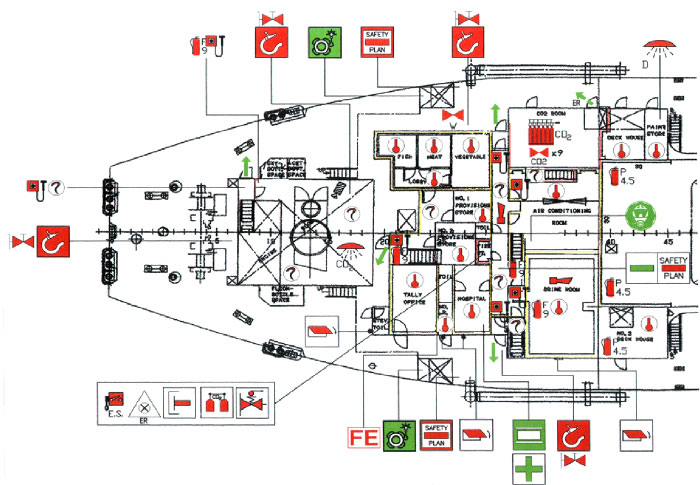

- The location of fire dampers can be found on the fire control plan.

- Louver type dampers are tested to ensure louver contact and function.

- Weathertight doors are closing properly and in accordance with load line regulations.

- Accommodation internal fire doors not tied back with ‘hooks.’

FIREFIGHTING EQUIPMENT

- The fire, smoke and heat detectors have been tested for proper operation.

- Fire detection panel displays with no faults.

- Fire stations have the appropriate equipment secured properly.

- Fire hoses are not leaking and have been checked for dry rot and usability.

- Fire hoses are of correct length and diameter for location (15m, 20m, etc.).

- Fire main is in good condition and does not have patches or holes.

- Isolation and relief valves are working properly.

- Portable and fixed firefighting systems have been serviced as required, and extinguishers are properly marked with date of servicing.

- Fixed firefighting systems have been serviced and do not have any loose hoses, and the system has been reactivated.

- Fire line isolating valve between the engine room (ER) and deck has been tested and is working properly.

- Foam systems where fit have had analysis samples taken and are operation-ready.

- Fixed water spray system valves are aligned and ready for immediate use.

- Access to fixed CO2 system (key in glass box) to be readily available.

FIRE CONTROL PLANS

- Fire control plans are up to date with appropriate IMO markings and symbols.

- Emergency control stations are clean and equipped with applicable safety equipment.

- Remote and quick closing devices are in good operating order.

- Updated crew list

LIFE JACKETS WITH LIGHTS AND WHISTLES

- The correct number and location are clearly shown on the safety plan and are located on board.

CABLE PENETRATIONS

- Cable penetrations in accommodation bulkheads (wheelhouse/radio room, etc.) are all effectively sealed.

CARGO AREA

LIFERAFTS

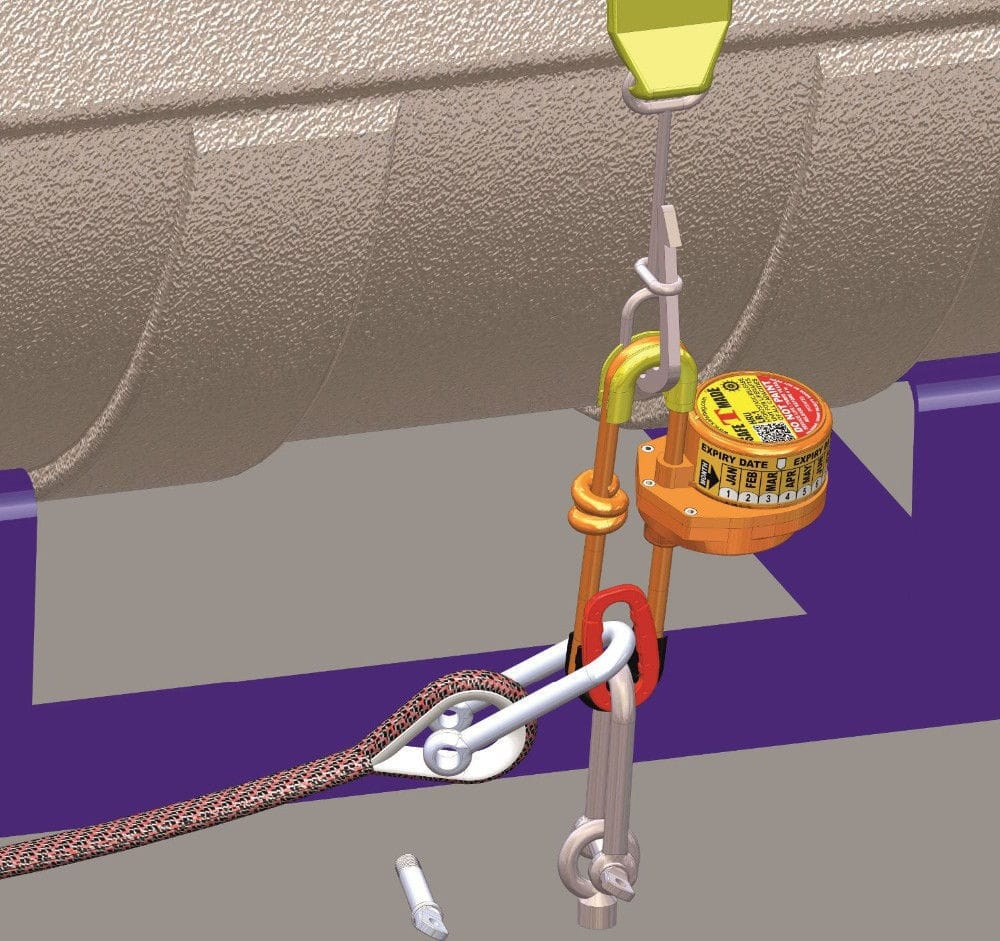

- Liferafts have been serviced by an approved servicing company.

- Liferaft hydrostatic releases are correctly connected and have valid service certificates and/or expiry dates. Liferafts are properly secured.

- Launching arrangements are in good condition (as applicable) with no obstructions for float-free operation.

LIFESAVING EQUIPMENT

- Lifebuoys – the correct number is identified by type with line, light or smoke as applicable and with legible vessel markings.

- Bridge wing Man-Overboard smoke and lights ready for easy release.

HATCH COVERS AND WEATHERTIGHT CLOSING APPLIANCES

- Hatch covers and weathertight closing appliances are in proper working condition and have been checked for missing or damaged gaskets, cleats, wedges and securing devices.

- Hatches are tight and properly fitted.

- Where required, there is safe access to the bow.

CARGO CONTROL ROOM

- Oil Discharge and Monitoring Equipment is functioning properly and has not been tampered with.

MAIN DECK

LIFEBOATS/RESCUE BOAT

- The lifeboat (rescue) structure (hull integrity, seats/ thwarts, flooring, releasing hook connections to the boat, releasing gear, tiller/gudgeons) has been checked for proper maintenance with no wastage or rot.

- The engine is in good working condition and has been operationally tested, and fuel tank is full.

- The lifeboat (rescue) equipment has been checked for proper quantity, expiration date and condition.

- Lifeboat/rescue boat painter is connected.

- Lifeboats (rescue) have been lowered as per schedule and released from hooks to confirm release mechanisms.

- Required interior equipment has been accounted for.

- Lifeboat seat belts are of contrasting colors.

- Lifeboat window at helmsman’s position has clear visibility.

- Lifeboat hatches are maintained.

- Lifeboat nonslip surfaces are maintained.

- Air supply system is maintained.

- Lifeboat water spray fire fighting system is maintained, if applicable

- Fuel tanks full and maintained

LIFEBOAT/RESCUE BOAT AND LIFERAFT DAVITS

- Davits are in good working condition and have been operationally tested.

- Davits should be checked for wastage, proper hoisting/lowering and braking function.

- Sheaves and loose gear are not worn.

- Wires have been serviced and changed out as necessary.

- Limit switches and winches have been tested.

- Launching instructions are clearly posted and located in way of emergency lighting.

DECK

- Excessive corrosion, cracking, buckling.

- Handrails are intact and in accordance with load line regulation.

AIR PIPES AND VENTILATORS

- Air pipes and closure devices are checked for wastage.

- Closure devices have been opened and the flame screen checked.

SHORE CONNECTIONS

- International shore connection is on board.

- Electrical shore connections have proper connections and are functioning.

- MARPOL Annex I and IV standard discharge connections where required have proper fittings, are marked, and have proper intact drip coamings.

ACCOMMODATION LADDER

- Accommodation ladders are free of any defects (fractured steps, side ropes etc.), and the gangway safety net has been prepared and correctly rigged.

VESSEL ACCESS

- Gangway log book entries are maintained and up to date.

- Areas with restricted access are clearly marked and locked.

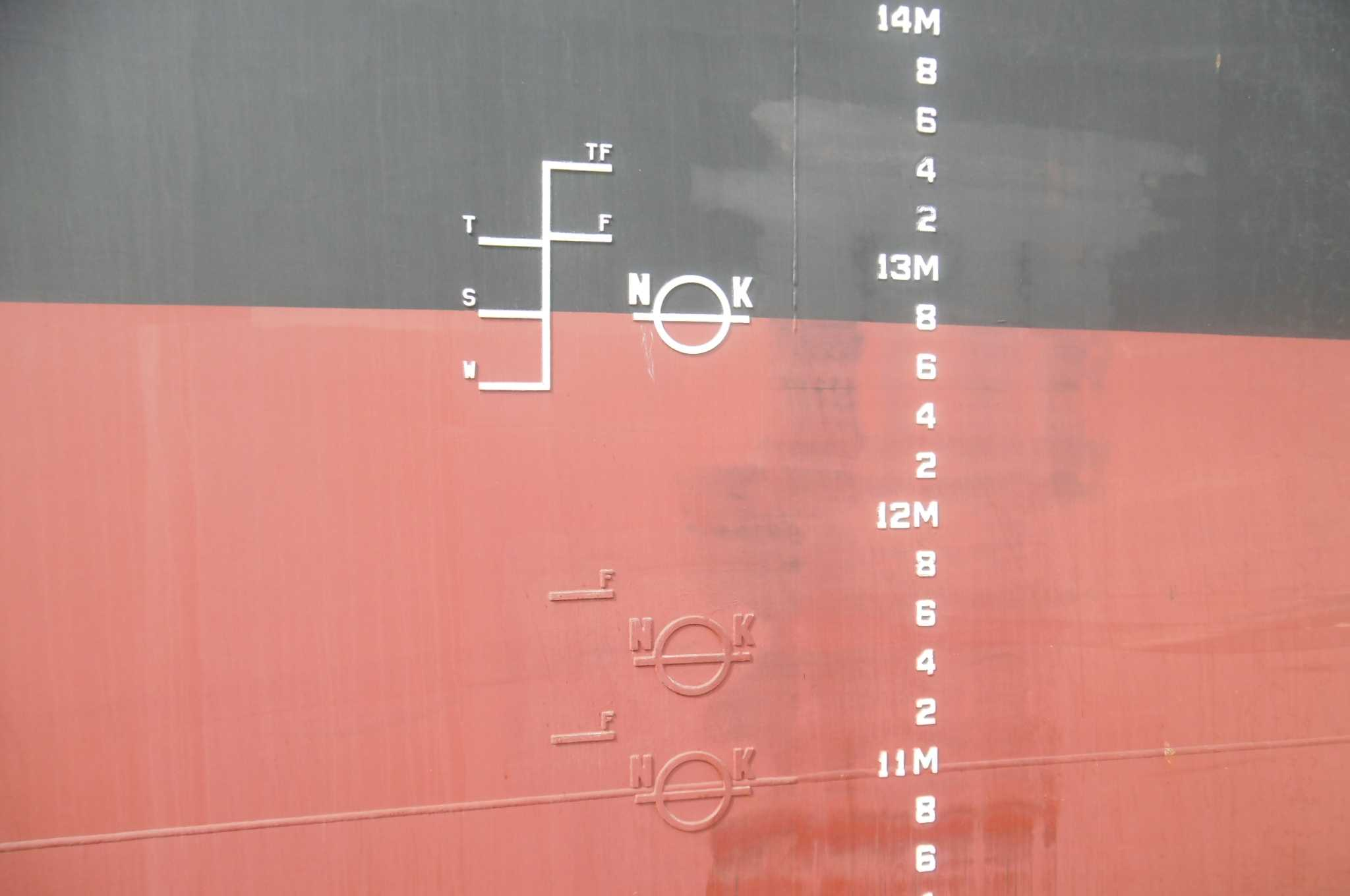

LOAD LINE – DRAFT MARKS

- Port and Starboard Load Line marks checked and confirmed to be clearly visible.

- Draft marks are clear to read.

ENGINE ROOM

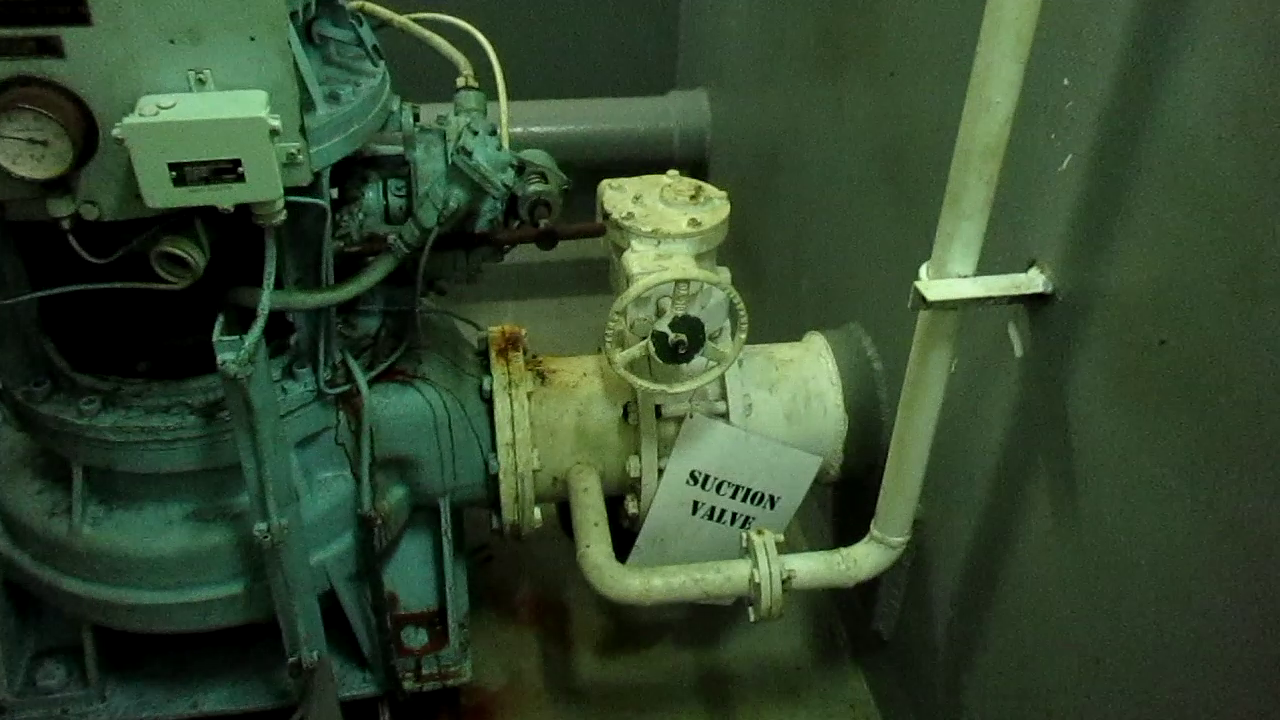

MAIN AND EMERGENCY FIRE PUMPS

- The main and emergency fire pumps are to be in proper working condition – gauges operational, priming pump functioning, remote starting is operational (if applicable) and pumps are capable of taking sea suction and maintaining the proper line pressure.

- Operating instructions are posted in plain view.

- Visual examination is completed of fixed firefighting system nozzles.

MACHINERY SAFETY SYSTEMS

- Valves are free from obstruction and are in operational condition.

- All machinery safety systems are operational without alarms present.

- All FO Tank sounding pipes are closed, and self-closing devices are working correctly.

ELECTRICAL INSTALLATION

- 220v main and emergency switchboards, and feeder panels are clear of any low insulation readings.

- Switchboards are to be provided with insulated matting both in front and behind.

CLEANLINESS

- Excess oil leaks from engines, bilges, containment areas and FO/LO processing areas have been cleaned.

- The sources of any excessive oil leaks have been rectified.

- Repair damaged lighting and/or replace burned bulbs.

- Fire hydrants and hose stations are clean and in good working order.

- No thermal insulation is oil soaked.

- No oil-soaked rags are left in decks or bilge wells.

- Tools and equipment are stored properly, and emergency exits are clear.

MARPOL ANNEX IV

- Sewage treatment plant is fully operational, including aeration blowers, sight tube, alarm panel, etc.

- Sewage treatment system is operational and not leaking.

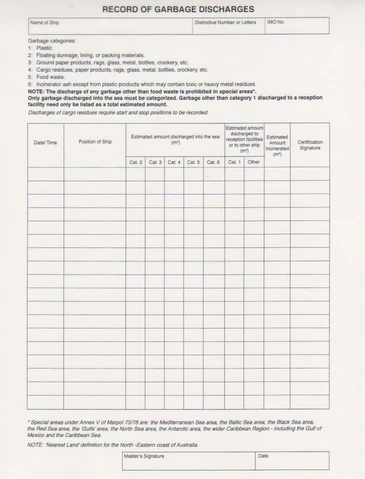

MARPOL ANNEX V

- Garbage Management Plan are available on board.

- Garbage Record Book entries are up to date.

- Incinerator alarms and safety devices are all fully operational.

MAIN PROPULSION ENGINE

- Components of the main propulsion engine are working correctly.

- The emergency control station and engine side station are operating correctly.

- Validate that emergency procedures can be carried out as applicable.

- There are no visible engine oil leaks.

- MARPOL Annex VI, technical files for each engine should be available.

- The record book of the engine parameters should be updated by the Chief Engineer as applicable.

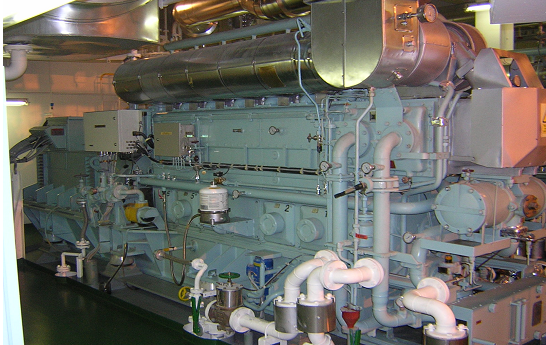

AUXILIARY ENGINES AND EQUIPMENT

- Auxiliary engines and attachments have been tested to see that gauges, emergency shut downs, automatic changeovers and quick closing valves are operating properly.

- Auxiliary engine fuel oil leakage alarms are working and drain valves are in closed position.

- MARPOL Annex VI, the EIAPP certificates and technical files for each engine should be available.

- The record book of the engine parameters should be updated by the Chief Engineer as applicable.

- There are no visible engine oil leaks.

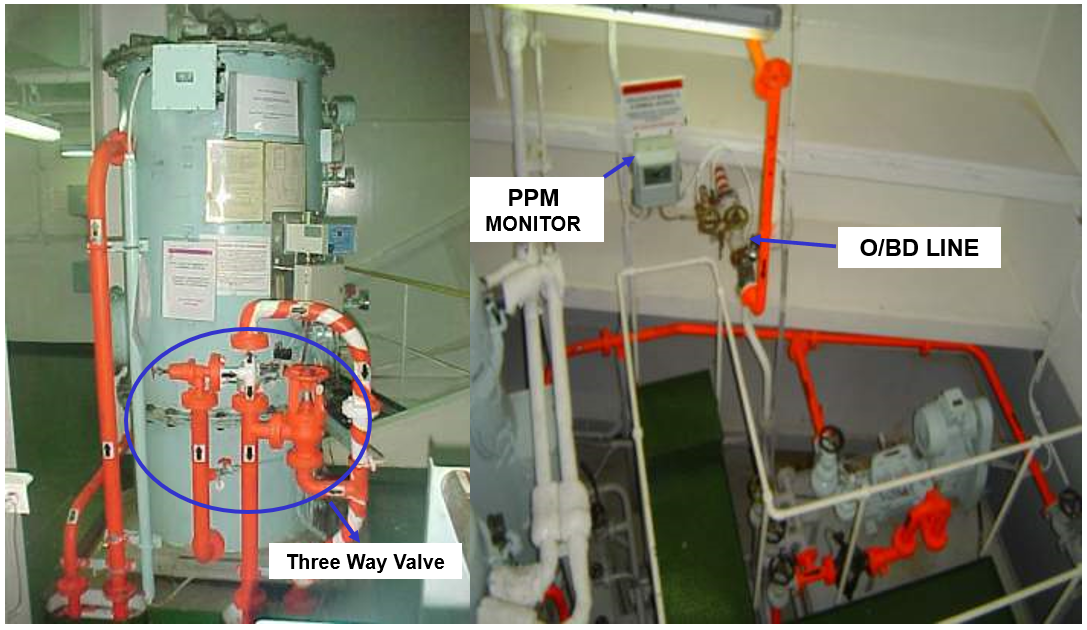

OILY WATER SEPARATOR EQUIPMENT

- Check to see that oily water separator equipment and 15 ppm alarm have been operationally tested including automatic stopping devices, alarms, piping systems and gauges, and found properly functioning.

- Confirm that no unauthorized piping or electrical modifications have been made.

- Verify that the Oil Record Book has been filled out correctly and signed by the Chief Engineer and Master, as per MARPOL Annex I.

HIGH PRESSURE FUEL LINES

- High pressure fuel lines are jacketed and spray shields in place as required.

PORTABLE AND FIXED FIREFIGHTING SYSTEMS

- Systems have been serviced as required and extinguishers are properly marked with date of servicing.

- Machinery space fire hoses are correct length (15m maximum).

- Boiler burner location is provided with sand box.

- Fire Doors have proper closing mechanisms and are not purposely open.

MARPOL ANNEX IV

- Valid IMO Type Approval Certificate is available.

- Manufacturer’s operating manual is available.

- Incinerator alarms and safety devices are all fully operational.

WORK SPACES (PUMP ROOM, STEERING FLAT, ETC.)

MAIN AND EMERGENCY FIRE PUMPS

- The main and emergency fire pumps are to be in proper working condition – gauges operational, priming pump functioning, remote starting is operational (if applicable) and pumps are capable of taking sea suction and maintaining the proper line pressure.

- Operating instructions are posted in plain view.

STEERING GEAR

- The main and emergency steering gear has been tested and is functioning properly with no visible hydraulic leaks.

- Steering gear gyro compass repeater without deviation error.

- Handrails, gratings or other non-slip surfaces provided and maintained.

EMERGENCY POWER

- The emergency generator has been operationally tested and is capable of coming online automatically within 45 seconds.

- Emergency generator fuel oil tank is full, and quick closing valve is operational.

- Emergency lighting is operationally tested,and any defective lights replaced.

- A transitional source of power (as applicable) and emergency power batteries have been checked for proper operation.

PORTABLE AND FIXED FIREFIGHTING SYSTEMS

- Systems have been serviced as required and extinguishers are properly marked with date of servicing.

INSULATION

- A-60 Insulation is intact in all areas (emergency escape trunks, etc.).