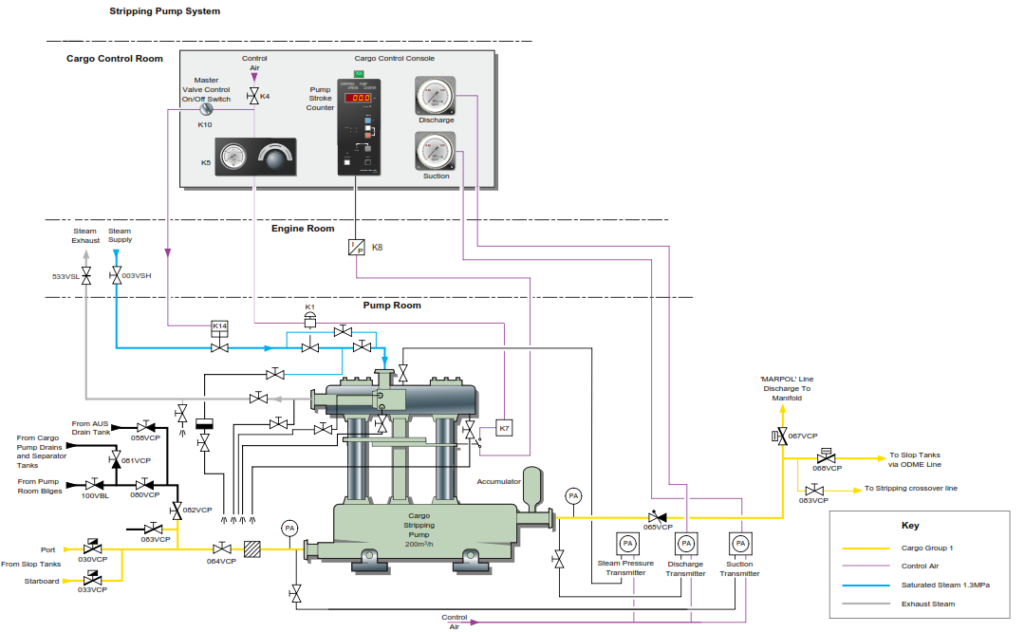

The stripping pump is a steam driven, double stroke, reciprocating type pump, controlled from the cargo console in the CCR. The stripping pump can be used to drain the cargo lines and the pump room bilges to the port or starboard slop tank, to shore via the 125mm line (MARPOL line), or if necessary to overboard via the ODME line with the ODME in operation.

The MARPOL line connects to the manifolds outboard of the manifold valves. It may also be used as a back-up alternative stripping device, along with a single stripping eductor.

Operation

Refer to above illustration

a) Ensure the stripping pump automatic lubricator is topped up with oil.

b) Slightly open the four drain valves on the steam chest and exhaust casing of the stripping pump.

c) Open the pump discharge valve and line valve to the MARPOL line if stripping to ashore, or valve to the port slop line and tank, or alternatively valve to slop to starboard slop if discharging to stbd tank.

d) Open the required pump suction valve and suction master valves, bilge suction or stripping master valve for cargo pumps and strainers.

e) Ensure the steam exhaust return valve in the engine room is open. Open the steam exhaust valve at the pump chest.

f) Open the drain valves on the steam exhaust line and inlet steam chest line to the pump.

g) Ensure that the speed setter control, in the cargo control console, is set at the minimum setting.

h) Ensure that an adequate steam supply is available from the engine room and that the main steam isolating valve in the engine room is open.

i) Open the speed setting bypass warming through valve.

j) After the warm up process, the pump can be started remotely from the cargo console in the CCR.

l) Close the speed setting bypass valve and all drain valves, then open the steam inlet isolating valve. Bring the pump up to speed using the speed setter control in the cargo console.

m) The speed is monitored by use of the stroke counter on the cargo console. The speed of the pump should not be taken above a maximum of 30 strokes/minute.

Stripper Stroke Controller

Note: Under no load conditions the speed of the pump will increase, therefore a good watch should be kept on the pump when it is coming to the end of suction.

Stripper Pump Panel in CCR

Instrumentation

Indication of the suction and discharge pressure are available in the cargo control room. A stroke transmitter is fitted to the pump. The air signal is sent to a stroke converter in the engine room, where the signal is converted to an electrical signal and passed to the stroke counter in the cargo control room console. The pump can be stopped quickly by closing the steam inlet valve by means of the master steam control switch in the cargo console. On closing the steam inlet valve, the stroke counter will continue to show the stroke at the time of closing for approximately 20 seconds after which it will show zero. The stroke counter will not display a count of less than 3 rpm.

Cargo and Ballast Stripping Eductors

The cargo oil and ballast stripping eductors are used for final stripping of tanks and in the case of the cargo oil stripping eductor, they are also used to keep the cargo oil tanks that are being COW’d almost dry.

Essentially the operating procedure for both sets of eductors is the same, just that the supply comes from a different source and that the cargo oil eductor discharges to either of the slop tanks, while the ballast eductor discharges directly overboard.

Operation

The driving fluid for the cargo oil stripping eductor can be supplied by any of the main cargo pumps. During COW operations the main cargo oil pump supplying the eductor will also be supplying a number of COW cleaning machines. The cargo oil pumps are each rated to be able to supply the eductor and a maximum of two cargo oil tanks and their respective cleaning machines.

It is important that the effective drive pressure does not drop too low so that the suction pressure is maintained. Additionally, there is the possibility that drive fluid may flow back to the tank through the eductor lines via an open suction valve.

When COW operations are taking place it should be noted that as there are two COW machines in the port cargo tanks and only one in the starboard tanks, the stripping suction valve in the starboard pair of tanks being COWd may require to be shut periodically during draining, this is in order that suction will not be lost in the starboard tank and an accumulation of oil in the port tank.

a) When the point is reached to use the stripping eductor, the speed of the cargo pump selected for drive duty should be reduced to allow effective changeover from bulk discharge to eductor operations.

b) When the pump is ready for operation set the line suction valves and eductor discharge valves to either slop tank. The port slop tank is designated as the dirty tank and the starboard tank is the clean tank.

c) Open the eductor drive valve . At this point the eductor suction valve must remain closed.

d) Increase the speed of the cargo oil pump and open its discharge valve, increase the pump speed until a minimum drive pressure of 1.0MPa is shown on the gauge. When a suction is shown on the eductor, open the suction valve.

Monitor the level in the slop tanks, if necessary the cargo oil pump suction can be taken from the port slop tank with the discharge from the eductor back into the port slop tank.