Anchor Work

Holding Power

Knowledge of the type of anchor on your ship is necessary because the holding power of each type is different. The holding power of an anchor is normally expressed in tonnes. The maximum holding power is reached when the anchor starts to drag but without reduction in its stability.

Holding efficiency = Holding power / Anchor deadweight

Cable Considerations

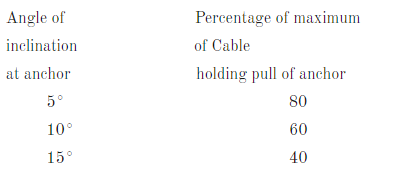

The anchor is most efficient when subjected to a horizontal pull by the cable on the seabed. The aim should be to ensure that enough cable is veered to achieve this situation.

If insufficient cable is veered to exert a horizontal pull at the anchor, its holding power will be reduced in accordance with the following scale:

When the ship drags her anchor, more cable is veered and the anchor holds. This action is correct, but the belief that it is the resistance of the extra cable on the seabed that lets the ship hold is a fallacy; the veering of the cable removed the shank/cable angle and the anchor holds once more.

Amount of Cable to Use

In addition, the amount of cable to veer depends upon a number of factors:

(a) Holding characteristics of the anchor.

(b) Length of stay.

(c) Strength of wind, tidal stream or current, and sea / swell.

(d) Swinging room.

(e) Type of cable.

(f) Depth/draught ratio.

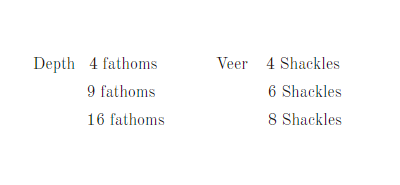

There are a number of guidelines given for the amount of cable to veer. The Admiralty Manual of Seamanship quotes the amount of cable to veer in shackles is twice the square root of the depth of water in fathoms.

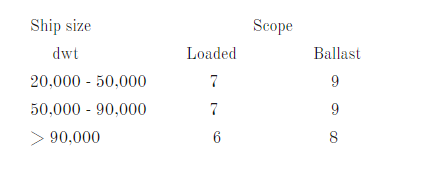

The scope used as a function of ship size is given below:

“Scope” is generally considered to be the ratio of the cable veered: water depth.

Type of Cable

The type of cable on the ship is also an important consideration. The three types are:

Mild steel grade 1

Special quality grade 2

Extra special quality grade 3

Grade 3 is the lightest; therefore, additional cable may have to be veered to ensure a horizontal pull.

Operational Aspects

When anchoring in an area where other ships are anchored, the approach course opposed to the resultant of the wind and current can be visually appreciated. This is more difficult to achieve when anchoring in an area devoid of other shipping, especially at night. The larger the ship, the smaller the limiting speed before dropping anchor. In a VLCC, the speed over the ground must be less than 0.5 knot. It is difficult to achieve a situation with the ship stopped over the ground.

A rule of thumb method often used is to reverse the engines until the propeller wash reaches the bridge or manifold (chosen by experience) and then let go the anchor. However, even if the experience of the master is such that he knows the ship is stopped through the water on these occasions, the ship is not necessarily stopped over the ground. Is a doppler log the answer? The wash from an astern movement can give errors of 1/2 knot. The log can also have been poorly calibrated. The Nautical Institute survey showed that only 35 per cent of VLCCs are fitted with bottom lock doppler speed logs.

Prior to anchoring, the set and drift of the current and wind should be established as well as possible and the ship placed on a heading opposed to the resultant of these forces. The anchor position should be marked on the chart and the forecastle officer briefed on the bridge.

In large ships, in order to establish that the ship is on the correct heading and the ship is stopped over the ground, the anchor should be lowered to the seabed, brake applied and taken out of gear. The cable should then be paid out slowly until the forecastle officer can use the lay of the cable to ascertain the correct ship’s heading. Provided that the length of the cable does not exceed twice the depth of water, the anchor will trip or drag, thus obviating undue stress on the shackle. Some pilots and masters prefer to carry out this operation with the anchor still in gear. When the forecastle officer is satisfied that the ship’s heading and headway are correct, then the rest of the cable should be paid out and finally brought up. Excessive sternway, once the anchor has dug into the seabed material, can cause some part of the shackle to fail or carry away. The inertia of large ships is considerable.

Dredging Anchor

Dredging with two anchor

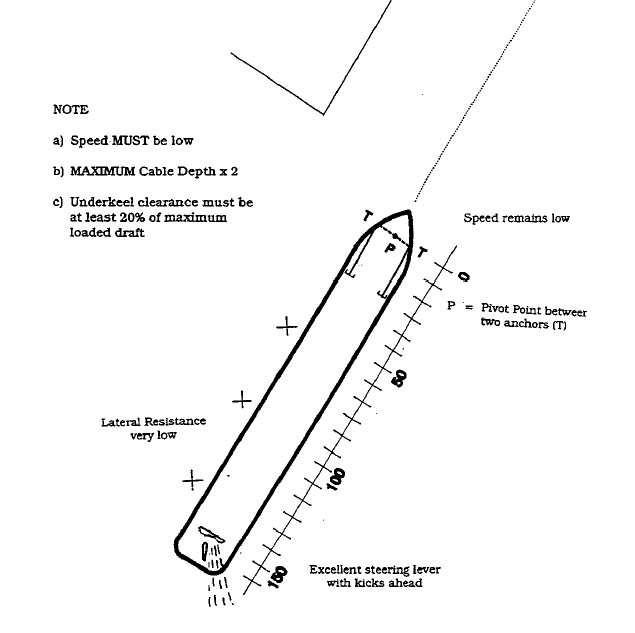

Dredging is remarkably effective at eliminating the two major problems that occur when berthing without tugs, namely control of heading and speed. The effect of dredging can be seen in figure .

The ship is conducting a dredge with two anchors, working into a port side berthing position. By dredging the two anchors the pivot point is brought right forward between the two windlasses. This gives the ship a much improved and excellent steering lever. The small weight of the two anchors is also surprisingly effective in controlling the speed of the ship.

Even whilst maintaining dead slow revolutions, the ship may gradually slow down and stop. This in turn ensures that the pivot point remains forward and that lateral resistance, which would otherwise oppose turning ability, is also kept low throughout.

The net result is an ability to keep the speed down, but at the same time use main power more efficiently when controlling heading with kicks ahead. The bow can virtually be driven on the anchors, to the desired position and more to the point will remain there. At the same time, the old enemy, speed is kept well under control!

Some Masters may express some concern as to whether two anchors being dredged will foul each other while the ship is turning. The answer to this is no because, if the ratio of cable to depth of water is correct, one anchor simply cannot reach the cable of the other; they should also be easy to recover once alongside.

Safety Parameters

Safety parameters within which to operate when dredging anchors.

a) The amount of cable in the water should not exceed 11/2 x depth of water. (Some sources quote 2 x depth). If this figure is exceeded the anchor is likely to dig in and commence holding.

b) The design speed of a windlass gypsy in gear is about 30 feet/minute which is approximately 3 minutes a shackle. This is equal to a ship speed of 0.3 knots over the ground.

c) The windlass is only designed to lift the dead weight of the anchor and four shackles.

If therefore, the amount of cable in the water does not exceed 1 1/2 x depth, we have a safety factor which guards against speeds in excess of 0.3 knot, because the anchors will not dig in and hold, but drag. (Some companies use 0.5 knot).

When the amount of cable exceeds 1 1/2 x depth, the speed must be below 0.3 knot, especially if the windlass is in gear or the brake is screwed up. The anchor will most certainly dig in and attempt to hold the full weight of the ship.

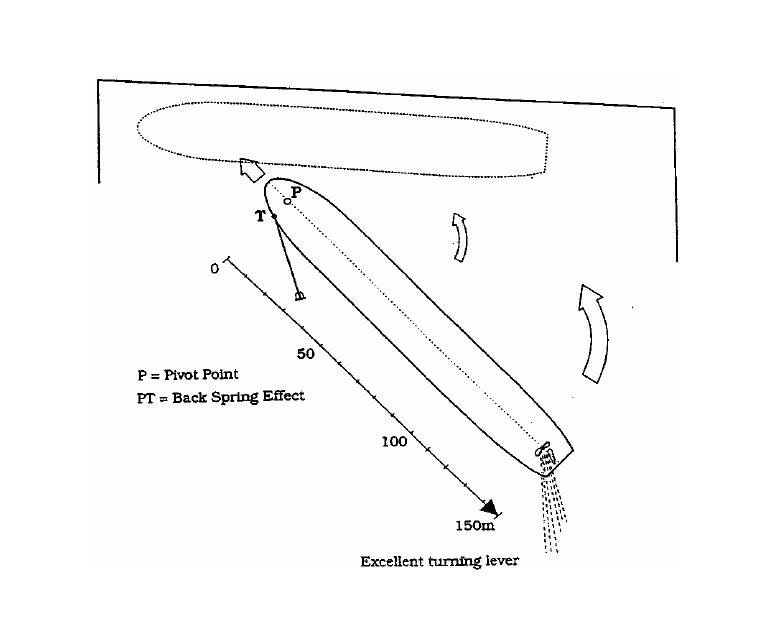

Dredging with one anchor

Generally speaking because pilots and masters have more experience of dredging one anchor than two, the question is frequently asked, “Why dredge two anchors?”. The answer is relatively simple: because dredging one anchor only achieves 50 % of the effect which could otherwise be gained by dredging two anchors. It is, therefore, not possible to use anything like the same amount of power for positioning the bow and the speed is nowhere near as easy to control.

By using one anchor, particularly on large beam ships, it should be remembered that the pivot point is moved out to the side. This creates an effective turning moment, in much the same manner as a back spring. This can quite clearly be felt and needs constant counter helm to correct, this can be irritating if a straight line approach is desired. On the other hand, if a large turn in confined waters is necessary prior to berthing then this tendency can obviously be utilised and turned to great advantage.

The single anchor can be viewed effectively as a back spring. The validity of these points should be considered when deciding whether to deploy one/two anchors.

Important Points

There is a very fine line between the success or failure of a dredging operation.

The following points are crucial in order to achieve the desired results:-

- Maintain the normal slow speed of approach prior to letting go, or walking out, the anchors. If the ship is stopped the anchors will dig in and it is then difficult to get underway again. The ship may also drift badly out of position.

- Walk the anchors out as early as possible. This gives sufficient time to get the feel of the ship before the berth is reached.

- Do not let the ship stop too early. This lets the anchor flukes drop and dig in and it then takes substantial power to get the ship underway again.

- Do not let the speed build up. This pushes the pivot point back to its normal position. Consequently the anchors cease to be effective and are of no use.

- Do not exceed 1 1/2 x depth. It is possible however, especially on small ships, to ‘feel’ the anchors and adjust the amount of cable accordingly.

- Keep the weight on the anchors. Going astern the ship will take the weight off the cables and they become ineffective.

- Avoid rushing the operation, particularly swinging, on large ships. There should only be a gentle and steady strain on the cable(s); the manoeuvre being slow but very effective.

- Once in position on the berth, slack back the cables as the tension in them is sufficient to pull the ship off the berth.