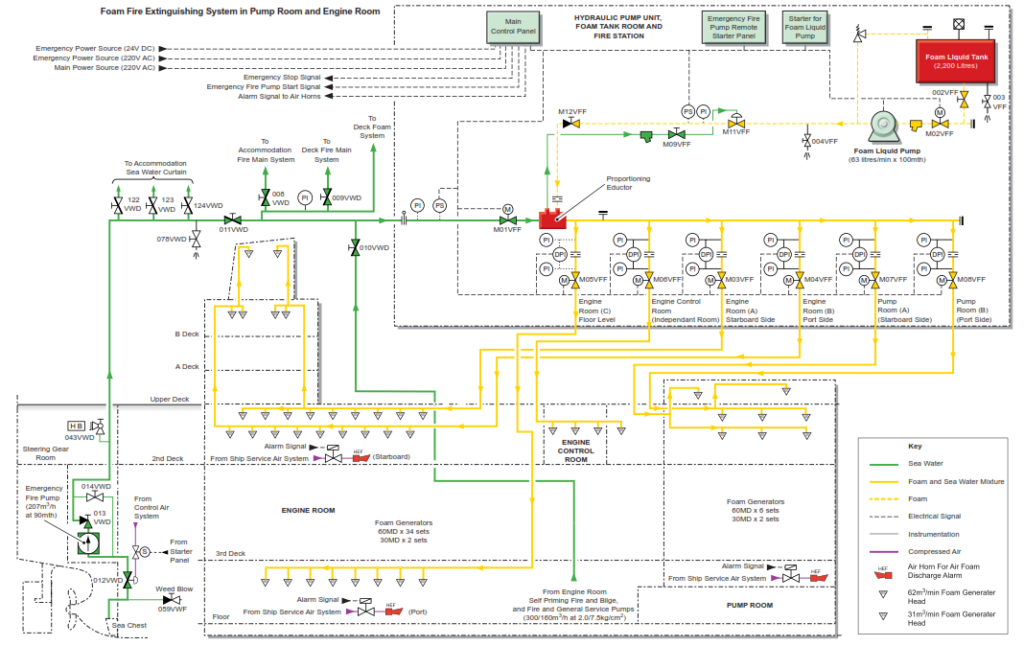

High expansion foam provides fire extinguishing capability by excluding oxygen from the seat of the fire and by the cooling effect caused by the evaporation of the foam bubbles. Foam is made by mixing a foam making chemical with sea water. The sea water is supplied from the emergency fire pump.

The foam liquid tank and foam liquid pump are located in the foam room/fire control station which is situated in the accommodation block cross alleyway on the upper deck. The foam room also contains the starter for the foam liquid pump, a local starter for the emergency fire pump, including the Open/Close buttons for the emergency fire pump’s pneumatically operated suction valve and a system control panel.

Foam is produced by mixing the foam liquid with water and injecting air into the mixture at the foam generators. The expansion rate of the foam when air is injected is 620:1. Foam is mixed with water in controlled quantities in a proportioning eductor and the resultant mixture is piped to foam generators located in those protected areas. At the foam generator foam is produced and as the foam mixture expands air is drawn in. At a sea water flow rate from the emergency fire pump of 207m3/h and a foam discharge rate of 63 litres/minute, the full discharge would take 34 minutes and will use approximately 120m3 of sea water.

High expansion foam is used to fight fires in the following protected spaces, each protected space having its own supply pipes and foam generators.

• Engine room 2nd deck port side area including the electrical store

• Engine room 2nd deck starboard side area including engineering store

• Engine control room (independent room) and switchboard rear access

• Engine room floor level

• Funnel uptakes

• Pump room upper deck

• Pump room 2nd deck

Each space has its own operating controls which are located in the foam room/ fire control station and the system is operated manually from the main control panel.

In order to allow for operation at any time a number of system valves are left open. The valves which must remain open are as follows:

| Description |

|---|

| Fire main cross-connection valve between emergency fire pump and engine room pumps |

| Fire main discharge valve into fire control room |

| Emergency fire pump discharge valve |

| Foam discharge valve to proportioning eductor |

| Foam liquid suction valve from foam tank |

| Pilot valve for foam discharge valve |

| Fire main discharge valve from engine room pumps |

Procedure for Operating the Hot Foam System

The system must only be operated in the event of a fire in the protected spaces and a decision must be made by the Captain/Chief Engineer to make use of the Hi-expansion foam system.

The system is operated manually from the control panel. The system requires local operation and is not controlled by the vessel’s automation system.

It is assumed that the emergency shut downs (and quick-closing valves, for engine room systems) and fan flaps and access doors have been operated/ closed as a first line of defence.

To Start the Pump Room System

a) Ensure that the emergency fire pump sea suction valve is open, if necessary open the valve from the pump start control panel. Break the destruct plate at the control panel and press the SYSTEM STANDBY pushbutton.

The alarm will sound for evacuation of the pump room, a check must be made to ensure that nobody is in the protected space.

b) The emergency generator and the emergency fire pump will start automatically.

c) The system senses that the water pressure is more than 0.4MPa and the indicator light on the control panel is illuminated.

d) After evacuation of the pump room is confirmed, the FOAM DISCHARGE push button must be pressed.

e) The foam pump will automatically start.

f) The sea water inlet valve to the proportioning eductor and the foam pump suction valve will open. Confirm that the valve open indicator lights on the control panel are illuminated.

g) The system senses that the foam pressure is more than 0.4MPa foam and the indicator light on the control panel is lit. The system discharges foam to the engine room by automatically operating the following valves:

| Position | Description |

| Open | Foam discharge to the port side area of the pump room |

| Open | Foam discharge to the starboard side area of the pump room |

h) Confirm that the valve open indicator lights on the control panel are lit. The time to fill the various levels in the pump room are as follows

| Area | Time |

| Floor | 2.9 minutes |

| Turbine deck | 4.1 minutes |

| 3rd deck | 5.4 |

| 2nd deck | 6.8 minutes |

| Upper deck | 8.2 minutes |

Foam is now being generated in all areas. Company procedures should be followed for subsequent actions by the ship’s company following a fire and activation of the fixed fire fighting system.

To Stop the System

a) Press the STOP SYSTEM pushbutton.

b) Manually stop the emergency fire pump.

Procedure for Cleaning and Preparing the Foam System after Use

a) After operation, drain out all the foam solution lines and blow the lines clear using fresh water and then compressed air.

b) Refill the liquid foam tank.

c) Check all the foam generators for fire damage.

d) Test the foam discharge lines using compressed air.

To Start the Engine Room System

a) Ensure that the emergency fire pump sea suction valve is open, if necessary open the valve from the pump start control panel. Break the destruct plate at the control panel and press the SYSTEM STANDBY pushbutton.

The alarm will sound for evacuation of the engine room, a check must be made to ensure that nobody is in the protected space.

b) The emergency generator and the emergency fire pump will start automatically.

c) The system senses that the water pressure is more than 0.4MPa and the indicator light on the control panel illuminates.

d) After evacuation of the engine room is confirmed, press the FOAM DISCHARGE pushbutton.

e) The foam pump will start.

f) The sea water inlet valve to the proportioning eductor and the foam pump suction valve will open. Confirm that the valve open indicator lights on the control panel are lit.

g) The system senses that the foam pressure is more than 0.4MPa, the foam indicator light on the control panel illuminates. The system discharges foam to the engine room by automatically operating the following valves

| Position | Description |

| Open | Foam discharge valve to the starboard side of the engine room. |

| Open | Foam discharge to the engine room floor deck level |

| Open | Foam discharge to the engine control room (Independent room) |

h) Confirm that the valve open indicator lights on the control panel are illuminated.

i) The foam/water mixture will be delivered to the foam generators.

j) After a delay of 3 minutes the following valves are automatically operated:

| Position | Description |

| Open | Foam discharge to the port side area of the engine room |

| Close | Foam discharge to the engine room floor deck level |

k) After a delay of 9 minutes the following valve is automatically operated:

| Position | Description |

| Close | Foam discharge to the engine control room |

k) Confirm that the correct valve indicator lights on the control panel are lit.

Foam is now being generated in all areas. Company procedures should be followed for subsequent actions by the ship’s company following a fire and activation of the fixed fire fighting system.

The nominal time to fill the various spaces, when there in no fire present is as follows:

| Area | Time |

| Floor | 3 minutes |

| 3rd deck | 5.6 minutes |

| 2nd deck | 8 minutes (ECR [Independent room] 9 minutes) |

| Casing | 11.3 minutes |

| Funnel | 13.3 minutes |

To Stop the System

a) Press the STOP SYSTEM pushbutton.

b) Manually stop the emergency fire pump.

After the fire has been extinguished and the space has cooled down the protected space must be thoroughly ventilated before any personnel enter the protected space. Without a hi-fog system to assist, it may take several hours for the foam to disperse, and it is inadvisable to start the ship’s ventilation system until it is absolutely certain that re-ignition will not occur. The high expansion foam is a last resort and once consumed, if a fire re-ignites, extinguishing it will be made very much more difficult.

A considerable amount of water will be pumped into the protected space during the foam discharge which will activate the bilge alarms, as access cannot be gained to confirm the cause, the only way to determine whether the alarms were activated by the foam or by other means, is to monitor the vessel’s draught.