OIL DISCHARGE MONITORING CONTROL SYSTEM

System

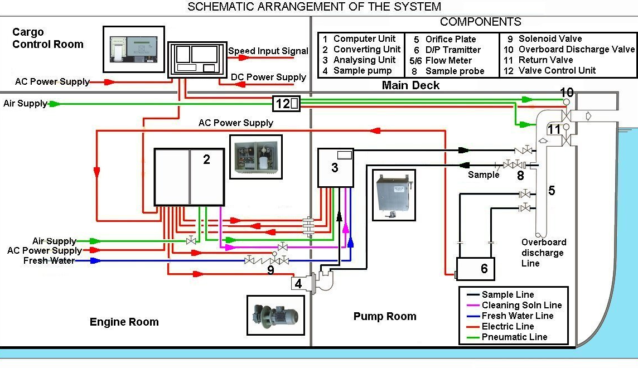

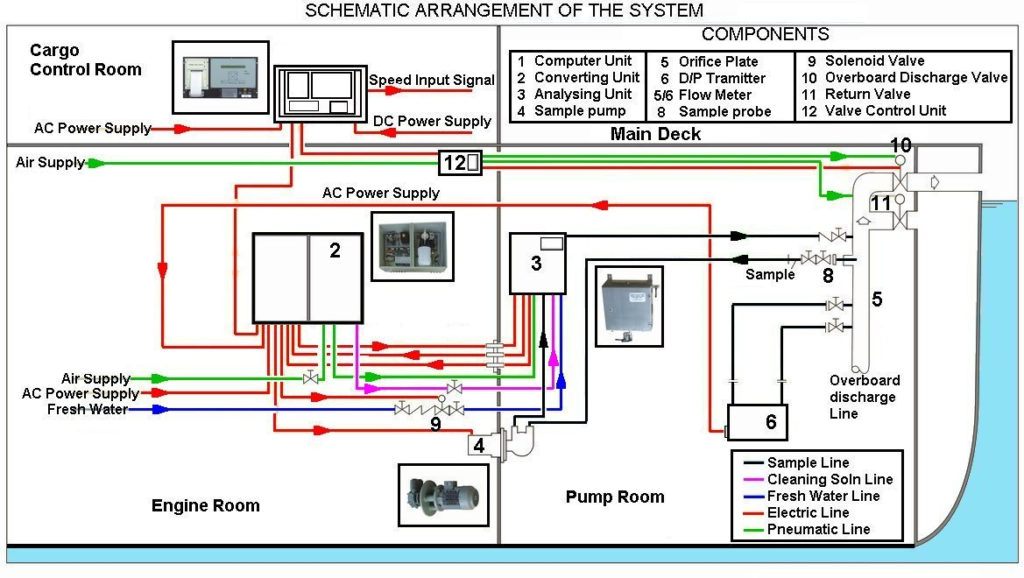

The system required shall be such that the three way valve to allow discharge of the oily water into the sea, shall open once the above condition are satisfied and will remain open until such time as the above conditions are not breached. As soon as the condition for the Instantaneous Rate of Discharge exceeds 30 L / NM, or the total quantity of oil pumped out into the sea exceeds 1/30000 of that parcel, the three way valve will stop the discharge over board. A continuous record is maintained of all operations. The equipment computer produces the stipulated permanent record of all facts related to the overboard discharge of oil contaminated water and provides the useful evidence, that the discharges have been made within the permitted limits.

The Measurement Principle

Normally a most reliable measuring principle system is based on a combination of light transmission and light scattering in four different angles. The sample water stream is homogenized in the sample feed pump and is passed through a quartz tube where it is exposed to a light beam in the infra-red part of the light spectrum.

The intensity of the light transmitted and scattered in the selected angles is dependant on the type and amount of contaminants and air in the water stream. Taking the different light scattering characteristics of non-oil contaminants as well as air bubbles into account, the computer can gain more precise signals.

Cleaning System for the Measuring Cell

Some systems feature a unique measuring cell cleaning system. Cold water flushing and mechanical brusher is no longer used. Instead a high pressure mixture of water and cleaning solution automatically flushes the measuring cell for a few seconds during each minute of operation and for some minutes during shut-down of the system. This flushing programme ensures that the cell is kept clean and effectively eliminates the risk for erroneous high oil content readings, which will cause false alarms and closing of the overboard discharge valve.

Calibration

Calibration is made of two liquids clean water “H20″ and a reference “REF” solution. High quality fresh water or distilled water as clean water is used. The reference solution is supplied as a concentrate by the manufacturers

P&I Advice on Oily water separation and discharge

Introduction

P&I clubs regularly monitor Port State detentions from various port state control organisations. In 2000, Gard club observed that there were a total of 131 detentions of ships entered in the Grad. Oily water separation and discharge related items were the single most frequent deficiency cited. Similar results were also observed in the detention of vessels entered in the Gard for 2000 (147 detentions and the second most cited deficiency).

Bilge Water Problems

On vessels in operation before the implementation of MARPOL 73/78, it was customary to pump the oily engine room bilge water straight overboard, even if an oily water separator was installed. Pipe systems were arranged so various pumps could be used as stand-by for each other, interconnected by valves and blind flanged connections. When the engine room pipe systems of existing ships were inspected for compliance with MARPOL 73/78 and issuance of the vessel’s first International Oil Pollution Prevention Certificate, such ‘useful’ connections had to be removed or blinded off. To maintain the possibility of an emergency discharge connection, careful Chief Engineers fitted chains and padlocks to valve handles. With time, illegal shipside valve connections disappeared or were blanked off permanently.

A warning outdated

On most vessels inspected, the Association finds that warnings of fines up to USD 5,000 are posted in engine rooms, in crew quarters and on the bridge. Under the US Federal Clean Water Act, an owner, operator or person in charge of an onshore or offshore facility could be fined up to USD 5,000 for oil discharged from such facility affecting US waters1. Prudent owners or Masters have obviously used the threat of a USD 5,000 fine as a tool to prevent the crew from discharging oil overboard, and the “Fine 5000” warnings have spread to ships never visiting US waters.

After the entry into force of the United States Oil Pollution Act of 1990, the “Fine 5000” stickers became obsolete, and may mislead the crew in respect of the implications of discharging oil overboard in US waters and elsewhere. Today shipowners not only may carry unlimited responsibility for the clean-up operation and the damage caused by an oil spill in US waters, but are also faced with strict criminal penalties for violations of US law. By spilling oil affecting US water, the offender risks criminal prosecution for spilling the pollutant and for failing to notify the government of the spill. Both individual violators and organisations may be penalised; individuals may even be imprisoned. For negligent violations, the maximum fine is USD 50,000 per day and one year imprisonment2. For “knowing violations”3 the imprisonment may be up to three years.

Under the Alternative Fines Act the maximum fine for an individual is USD 100,000 (negligent) and USD 250,000 (knowingly). For an organisation the fines are doubled. If an individual or an organisation derives pecuniary loss to a third party, the fine will be up to twice the gross gain or loss, which, depending on the circumstances could run to millions.

New US warning

US regulations require every ship above 26 feet in length to have a placard of at least 5 x 8 inches made of durable material fixed in a conspicuous place in each machinery space, or at the bilge and ballast pump station, with the following message, in a language understood by the crew:

“Discharge of Oil Prohibited. The Federal Water Pollution Control Act prohibits the discharge of oil or oily waste into or upon the navigable waters of the United States, or the waters of the contiguous zone, or which may affect natural resources belonging to, appertaining to, or under the exclusive management authority of the United States, if such discharge causes a film or discoloration of the surface of the water or causes a sludge or emulsion beneath the surface of the water. Violators are subject to substantial civil penalties and/or criminal sanctions including fines and imprisonment.”

Old warning-placards may be left in place, but new ones should be added and all crewmembers should be informed that the time of a maximum USD 5,000 fine is now history. There should be no excuse for not using the new placard, as it may be obtained easily through ship chandlers.

Some good advice

- A copy of MARPOL 73/78 should be kept on board. The crewmembers should be made fully aware of the regulations.

- Ensure the vessel has a valid IOPP certificate at all times.

- The Oil Record Book must be correctly filled in. Port State inspectors will inspect the book and may check the vessel’s sludge tanks. If the vessel has no sludge on board and has no record of delivery, the Master and Chief Engineer are likely to be fined.

- The oily water separator installed on board must be of an approved type and function well.

- The oil content meter, the monitoring device and the alarm/automatic-stopping device must function correctly.

- When purchasing a second hand vessel, visually check all lines from sludge and oily bilge water tanks to verify that no oily bilge water line or sludge line may discharge directly overboard. If one such connection is found, remove it immediately. If in doubt, consult the vessel’s Classification Society.

- The placard with warning against the discharge of oil overboard must reflect the true penalty situation faced by the crew and operator.

- Reduce the oil leakages to the bilges by collecting oil in drip trays and gutters leading to a waste oil tank. Be sure the drainpipes from the gutters are not clogged by deposits and rags.

- Oil sludge from engine rooms is not to be pumped overboard. If not disposed of in an incinerator, the oil must be contained on board until discharged to shore-based reception facilities.

P& I cover

Members should be aware that the Associations Rules do not include cover for the Member’s liability for fines resulting from non-compliance with the provisions contained in MARPOL 73/78.