Oil cargoes, like any other substance, can be measured in volume or weight. The volume will vary with temperature and hence it should be expressed in standard units so that a comparative study can be made. Temperature is measured in degrees Fahrenheit or degrees centigrade. The standard temperature used for all cargo calculations is 15º C or 60º F. Conversion from one to the other can be done by the tables provided or by the formula,

C / 5 = (F- 32) / 9

Once the volume of the cargo is calculated at the standard temperature the weight of the cargo can be calculated. Multiplying the volume of the oil at standard temperature by the density of the cargo at the standard temperature in vacuum, gives the weight of the cargo in vacuum and by multiplying the volume at standard temperature, by the weight reduction factor the weight of the cargo in air can be determined.

Accuracy of measurement

Normally the Bill of lading figure is based on the shore figure. This is because the measurement of cargo is more accurate when it is done in a shore tank. But recently there have been a few cases of claims against the ship due to voyage loss. This voyage loss was attributed to loss due to venting of vapour and due to leakage, etc. whereas the actual reason was inaccurate cargo figures inserted on the Bill of lading. Hence obtaining an accurate figure of the amount of cargo received on board is important so that it can be compared with the Bill of lading figures and a protest can be issued by the vessel in case of difference between the two. The quantity of cargo on board at load port and at discharge port is calculated to determine difference, if any. Normally voyage charter parties allow for 0.01% voyage loss, but this needs to be confirmed for every charter party. Calculation of the volume of liquid in a small container would be an easy process but this is difficult on a ship due to various factors such as:

- Movement of the surface of the liquid in the tank due to the movement of the ship in the water. This may be due to swell, due to wake of other ship passing by. The ship may have a small trim or list, which may be difficult to determine and apply, etc.

- Shape of the tanks. Here it should be noted that the calculated volume of the ships tanks is not very accurate and the volume calculated at various depths will have a certain amount of error due to the shape of the tank.

- Inaccuracy of the equipment used in gauging the tanks. The accuracy of the ullage would depend on the accuracy of the ullage tape / electronic tape or the radar gauge or any such other gauge used. Likewise the accuracy of the temperature will depend on the accuracy of the thermometer and the reduction of the effect of the external temperature on the reading.

- Human Error

Cargo calculation;

Use of tank calibration tables and given cargo density to calculate the weight in a tank.

Every ship is provided with tank calibration tables. On any ship, the calibration tables provided are for the fresh water tanks, ballast water tanks, bunker tanks and such other tanks, which may contain liquids. These tables have the volume of liquid in the tank tabulated against the sounding, for the ship in upright and even keel condition. In case the vessel is listed or trimmed, a correction table is provided to correct the sounding.

For an oil tanker calibration tables are provided for cargo spaces. These tables give the volume of the liquid in the tank against the ullage. (Ullage is the least depth of the surface of the liquid from the reference point on top of the tank.) The volume obtained from the ullage tables also has to be corrected for trim and list. Some tankers are also provided with wedge tables, which give the volume of liquid in the tank against the sounding when the tank is nearly empty i.e. the liquid does not extend to the forward bulkhead of the tank. These wedge tables can be used only when the ship has a trim by stern i.e. the liquid is touching the aft bulkhead but not the forward bulkhead. If the liquid touches the forward bulkhead, these wedge tables cannot be used.

Definitions of terms used in cargo calculations

Corrected Ullage: Ullage corrected for trim and list of the ship.

Free water: This is the quantity of water that has been mixed with the cargo and which is in suspension in the cargo. Free water requires at least 24 hrs to settle. Hence a remark is always inserted in the ullage report at load port that sufficient time has not been allowed for the free water to settle. This covers the vessel’s responsibility if free water is found at discharge port.

Note: Water found at the discharge port is attributed to the ship and hence the onus is on the vessel to prove that the water was loaded as a part of the cargo at the load port and that the vessels cargo system did not cause the water ingress. The vessel has to take all reasonable precautions to ensure that the sea water or water from the ballast tanks does not leak into the cargo tanks. The sea chest valves are always sealed at the load port and this seal should be intact on arrival at discharge port. In older vessels where the cargo lines passed through ballast tanks or the ballast lines passed through the cargo tanks, there was always a possibility of the line getting holed or the expansion coupling leaking there by allowing water to leak into the cargo.

Gross Observed Volume (GOV): This is the volume of the cargo in the tank at observed temperature and is obtained by subtracting the quantity of free water in the tank from the TOV.

Gross Standard Volume (GSV): The volume of cargo at the standard temperature is called gross standard volume. This is obtained as a product of the Gross Observed Volume (GOV) and the Volume Correction Factor (VCF).

On Board Quantity (OBQ): The quantity of cargo residue in the tank determined before commencement of loading operations. This may be in fluid or non-fluid form. Even though the OBQ is obtained at observed temperature, since its quantity is small it is considered to be at standard temperature and is subtracted from the GSV of the cargo in the tank to obtain the GSV of cargo loaded.

Remaining On Board (ROB): ROB is the quantity of cargo remaining on board after completion of discharge. This may be in fluid or non-fluid form.

Total Observed Volume (TOV): This is the volume of the liquid in the tank at observed temperature as obtained from the ullage tables by the use of the corrected ullage.

Volume Correction Factor (VCF): The volume correction factor is the factor used to convert the volume at observed temperature to obtain the volume of the cargo at standard temperature.

Weight Reduction Factor (WRF): The factor, which is used to determine the weight of the cargo from the GSV.

Calculation of the volume of the liquid cargo

When cargo calculations have to be made, the tanks are gauged. Note the following during gauging:

- The depth of the surface of the liquid from the lip of the ullage port (i.e. the reference point) is measured with an ullage tape or with an electronic tape (such as a UTI or MMC.)

- This ullage may be obtained remotely if the ship is equipped with radar gauging system, or a float gauge system. The reading of the depth of the liquid from the reference point is called ‘observed ullage’.

- The temperature of the tank is obtained, preferably at three levels, so as to get the average temperature of the tank.

- A water dip is taken to gauge the amount of water in the tank. (To take water dip, water finding paste is applied to the bob and some part of the sounding tape and the tape is lowered into the tank until the bob touches the bottom of the tank. The tape is then wound and the paste is checked for any discoloration. This discoloration indicates the presence of ‘free water’ in the tank. The sounding of the free water is read off from the discoloration.)

- After all the tanks have been ‘gauged’, the vessel’s drafts forward and aft are obtained.

- Vessel’s trim and list should be determined for use in calculating the cargo. The trim and list should not be changed during gauging.

- The trim and list correction for each tank shall be determined and is applied to the observed ullage to obtain the corrected ullage.

- The corrected ullage of the tank can now be entered in the table for that tank and the total observed volume (TOV) is obtained.

- From the TOV of each tank, the quantity of free water, obtained by entering the water dip reading for each tank, in the tables provided, is subtracted. The volume obtained by subtracting the quantity of free water from the TOV is called gross observed volume (GOV).

- Using the volume correction tables, the volume correction factor (VCF) is obtained. The product of the GOV and the VCF is the GSV.

- The product of the GSV and the WRF give the weight of the cargo loaded.

Use Of Volume Correction Table

The volume correction tables used for crude oils are called ‘A’ table, and those used for products are called ‘B’ table. Thus tables ‘6’A, ‘24’A and ‘54’A are used to calculate the VCF for crude oils and ‘6’B, ‘24’B and ‘54’B are used to calculate VCF of petroleum products.

Table ‘6’ (A & B) are used when the API of the cargo is given. If the API is at observed temperature then it is converted into API at 60º F, by using table ‘5A or 5B’. The API at 60º F is used to enter the ‘6A or 6B’ tables against the observed temperature, to obtain the VCF. When the gross observed volume (GOV) is multiplied by the VCF the gross standard volume (GSV) is obtained. The unit for volume used in this case is ‘Barrels’ and for temperature is ‘Fahrenheit’.

Table ‘24’ (A & B) are used when the specific gravity of the cargo is given. The specific gravity (Sp. Gr.) at observed temperature is converted to Sp. Gr. at 60º F by use of table ‘23A or 23B’. The Sp. Gr. at standard temperature is entered against the observed temperature to obtain the VCF. When the GOV is multiplied by the VCF obtained from table ‘24A or 24B’, the GSV is obtained. The unit for volume is ‘Barrels’ and for temperature is ‘Fahrenheit’. In the new petroleum measurement tables the term Sp. Gr. has been replaced by ‘Relative density’.

Table ‘54’ (A & B) are used when the density of the cargo is given. The density of cargo at observed temperature is converted to density at 15º C by using table ‘53A or 53B’. The density at standard temperature is entered against observed temperature to obtain the VCF. When the GOV is multiplied by the VCF obtained from table ‘54A or 54B’ the GSV is obtained. The unit for volume is ‘Cubic meters’ and for temperature is ‘Centigrade’.

GSV obtained is constant as it is at a standard temperature. The volume of cargo used for comparison is the GSV.

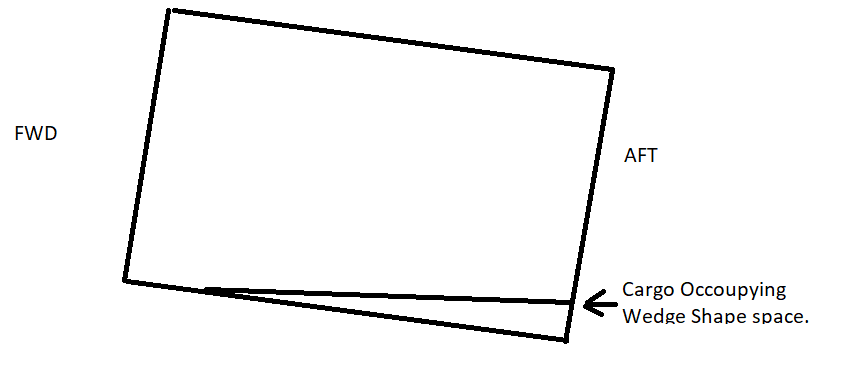

Wedge Calculation

On completion of discharge, the ship’s tanks should be empty so that the vessel can be given a dry tank certificate to indicate that the ship has discharged all the cargo that she had on board on arrival. It is sometimes not possible to strip all the cargo from the tank due to various reasons. The cargo remaining is a small quantity and is normally collected at the after end of the tank due the stern trim of the vessel. If the cargo is not upto the forward bulkhead of the tank then the ullage tables cannot be used, as they are not valid if the cargo does not cover the entire tank top. The cargo which has a volume shaped like a wedge is calculated by wedge calculations as shown below in the tables.

| Tank | U | – DF | x F | + S | = A | A2 | x W | x B | ÷ F | BBLS |

U = Distance from ullage point to after bulkhead

DF = Mean gauge height X trim factor

F = Trim factor

S = Sounding

A = Adjusted innage (sounding) at after end of tank

W = Width of tank

B = If measurements used above are in feet then B = 0.08905

If measurements used above are in metres then B = 3.1449

Calculation of basic information required for above calculation

| Draft aft | |

| Draft forward | (-) |

| Trim | = |

| LBP | ÷ |

| Trim factor (F) | = |

| Mean gauge height | X |

| DF | = |

| API | |

| Temp on arrival | |

| Sea temperature |

Calculating the weight of the cargo

To obtain the weight of the cargo, the GSV is multiplied by ‘Weight reduction factor’ (WRF).

When using table ‘6’ (API of cargo) the WRF is obtained by entering tables 11 and 13 which give ‘Barrels per long ton’ and ‘Barrels per metric ton’ respectively.

When using Sp. Gr. (R.D.), the WRF of the cargo in long tons, is obtained by using table 29.

When using density at 15º C, it should be noted that the density is always in vacuum unless specified otherwise. The weight of the cargo in vacuum is obtained by multiplying the GSV by the density at 15º C in vacuum. To obtain the weight of the cargo in air, the GSV is multiplied by the WRF, which is obtained by subtracting 0.0011 from the density at 15º C in vacuum. If the density at 15º C is in air then GSV multiplied by the density gives the weight of the cargo in air. The unit of weight is metric tons and to convert to long tons the conversion factor should be used.

It should be noted that the OBQ should be deducted from the GSV to obtain the volume of the cargo loaded.

To calculate the ullage of a tank to allow for expansion of the cargo

- When calculating the final ullage of a tank, the prudent method is to first determine the highest temperature that the cargo is expected to reach (due to heating or due to high ambient temperature).

- Then assume that the tank will be at 98% volume at this temperature. (It should be noted that under no circumstances is a tank loaded to more than 98% of its volume.)

- With the density of the cargo at 15º C (or API at 60º F) the appropriate VCF tables are entered and the VCF, at the maximum temperature that the cargo may attain, is obtained.

- The maximum volume (98% of tank capacity) that the tank may attain is multiplied by the VCF to obtain the GSV.

- Now the VCF for the present temperature can be obtained from the same VCF tables and when the GSV is divided by this VCF, the volume of the cargo at observed temperature could be obtained.

- The ullage can now be read off from the ullage tables of that tank, for the corresponding volume.

- This ullage is at even keel and upright condition. If vessel has list or trim then appropriate corrections have to be obtained from the correction tables and applied to the ullage at even keel and upright condition.

- This corrected ullage will be the ullage to which the tank may be loaded under present conditions so as to never exceed 98% volume in the tank.

ASTM TABLES

Brief Overview

For calculation of the quantity of a product, Surveyors use GOST specifications, as well as the international system ASTM. In Russia and in most of East-European countries, the consument value is determined according to GOST, which means that the mass of loaded product is expressed in kg-vacuum at 20°C temperature.

This collection of volume-correction-factor and related tables is used worldwide in custody, transfer and accounting operations to adjust bulk volumes of crude oil and products measured at temperatures other than base temperature (60 Degrees F or 15 Degrees C) to the base temperature.

The tables, which have been approved by ASTM, the American Petroleum Institute, and the Institute of Petroleum (United Kingdom), supersede all previous editions of ANSI/ASTM D 1250, IP 200, and API 2540and have been adopted as an international standard by the International Organization for Standardization.

New developments

The 3 sets of previously published tables were in terms of API gravity (Tables 5 & 6), specific gravity (Tables 23 & 24), and density in kg/m3 (Tables 53 & 54). Tables 23 & 24 are now in relative density units. For accuracy and convenience, 2 or 3 separate tables replace each previous table. For example, Table 6 has been superseded by 6A. Generalized Crude Oils; 6B, Generalized Products; and 6C, Volume Correction Factors for Individual and Special Applications.

Volume X contains computer subroutine listings, example problems and instructions necessary to use the computer subroutines. Use of this volume with a computer subroutine is a major conceptual departure from previous versions of the tables and recognizes the increasing use of computers to calculate volume correction in the petroleum industry. The actual standard is neither the printed tables nor the set of equations used to represent the density data, but is an explicit implementation procedure used to develop computer subroutines. Strict adherence to the procedures will ensure that all computers and computer codes of the future will produce identical results.

Volume I: Petroleum Measurement Tables

Table 5A – Generalized Crude Oils, Correction of Observed API Gravity to API Gravity at 60 Degrees F

Table 6A – Generalized Crude Oils, Correction of Volume to 60 Degrees F against API Gravity at 60 Degrees F

Volume II: Petroleum Measurement Tables

Table 5B – Generalized Products, Correction of Observed API Gravity to API Gravity at 60 Degrees F

Table 6B – Generalized Products, Correction of Volume to 60 Degrees F against API Gravity at 60 Degrees F

Volume III: Petroleum Measurement Tables

Table 6C – Volume Correction Factors for Individual and Special Applications, Volume Correction to 60 Degrees F against Thermal Expansion Coefficients at 60 Degrees F

Volume IV: Petroleum Measurement Tables

Table 23A – Generalized Crude Oils, Correction of Observed Relative Density to Relative Density 60/60 Degrees F

Table 24A – Generalized Crude Oils, Correction of Volume to 60 Degrees F against Relative Density 60/60 Degrees F

Volume V: Petroleum Measurement Tables

Table 23B – Generalized Products, Correction of Observed Relative Density to Relative Density 60/60 Degrees F

Table 24B – Generalized Products, Correction of Volume to 60 Degrees F against Relative Density 60/60 Degrees F

Volume VI: Petroleum Measurement Tables

Table 24C – Volume Correction Factors for Individual and Special Applications, Volume Correction to 60 Degrees F against Thermal Expansion Coefficients at 60 Degrees F

Volume VII: Petroleum Measurement Tables

Table 53A – Generalized Crude Oils, Correction of Observed Density to Density at 15 Degrees C

Table 54A – Generalized Crude Oils, Correction of Volume to 15 Degrees C against Density at 15 Degrees C

Volume VIII: Petroleum Measurement Tables

Table 53B – Generalized Products, Correction of Observed Density to Density at 15 Degrees C

Table 54B – Generalized Products, Correction of Volume to 15 Degrees C against Density to 15 Degrees C

Volume IX: Petroleum Measurement Tables

Table 54C – Volume Correction Factors for Individual and Special Applications, Volume Correction to 15 Degrees C against Thermal Expansion Coefficients at 15 Degrees C

Volume X: Petroleum Measurement Tables

Background, Development, and Computer Documentation

Volume XI/XII: Petroleum Measurement Tables

Intraconversion Between Volume Measures and Density Measures which contains Tables 1, 2, 3, 4, 8, 9, 10, 11, 12, 13, 14, 21, 22,26, 27, 28, 29, 30, 31, 33, 34, 51, 52, 56, 57, and 58.

Calculations according to ASTM are based on the procedure where a volume measured at a given temperature, is recalculated to a volume at the standard temperature, using the volumetric correction. This corrected value is called Standard Volume. Using the Standard Volume and the product’s density at the standard temperature, surveyors determine the mass of the product.

In general terms, calculation of mass based on the measurement of volume, is done in the following way. First, the volume and the temperature of the product in a vessel or in a shore reservoir are measured. This Total Observed Volume should be corrected to account for the differential, tilt, underlying water, floating roof etc. The corrected value of volume is then reduced to the volume at the standard temperature – Gross Standard Volume (GSV.). In order to translate the Observed Volume into the Standard Volume, the Volume Correction Factor (VCF.) is used, which can be found in ASTM tables. Then, the obtained value of Standard Volume is multiplied by the product’s density, which yields the product’s mass.

The Volume Correction Factors are of three kinds, according to the type of the product:

ASTM tables 6-24-54-A: for crude oil;

ASTM tables 6-24-54-B: for oil products, gas oil, diesel fuel, kerosene, gasoline, nafta

ASTM tables 6-24-54-D: for lubricating oils.