Construction and Maintenance

In any dock, all parts, whether fixed or moveable or every lifting machinery and every chain, ring, hook, shackle, swivel or pulley block used in hoisting or lowering shall be:

Of good construction, sound material, adequate strength and free from defects;

Properly maintained; and Thoroughly examined once at least every 12 months and particulars of such examination entered in the register approved by the inspector. (Chain Register)

What is a Chain Register?

This register is the standard international form as recommended by the International Labour Office in accordance with the ILO Convention No. 152.

The tests, examinations and inspections indicated in this register are based on the requirements of ILO Convention 152 and Recommendation 160. They are intended to ensure that ships having lifting appliances are initially certified by a competent person, and to establish periodically that they continue to be in safe working order to the satisfaction of a competent person acceptable to a competent authority . A Register of lifting appliances and items of loose gear shall be kept in a form prescribed by the competent authority, account being taken of this model recommended by the International Labour Office. This Register and related certificates shall be kept available to any person authorized by the competent authority. The Register and certificates for gear currently aboard the ship shall be preserved for at least five years after the date of the last entry.

Definitions

(a) The term “competent authority” means a minister, government department, or other authority empowered to issue regulations, orders or other instructions having the force of law.

(b) The term “authorised person” means a person authorised by the employer, the master of the ship or a responsible person to undertake a specific task or tasks and possessing necessary technical knowledge and experience for undertaking the task or tasks.

(c) The term “competent person” means.-

(i) a person belonging to a testing establishment in the Government who is approved by the Chief Inspector for the purpose of testing, examination or annealing and certification of lifting appliances, loose gears or wire ropes;

(ii) any other person who is recognized under the relevant regulations in force in other countries as competent for issuing certificates for any of the purposes mentioned in sub-clause (1) for the implementation of the Protection against Accidents (Dockers) Convention (Revised), 1932 (No. 32) and the Convention concerning Occupational Safety and Health in Dock Work (No. 152), 1979, adopted by International Labour Conference.

(d)The term “thorough examination” means a detailed visual examination by a competent person, supplemented if necessary by other suitable means or measures in order to arrive at a reliable conclusion as to the safety of the lifting appliance or item of loose gear examined

(e) The term “lifting appliance” covers all stationary or mobile cargo handling appliances used on board ship for suspending, raising or lowering loads or moving them from one position to another while suspended or supported.

(f) The term “loose gear” covers any gear by means of which a load can be attached to a lifting appliance, but which does not form an integral part of the appliance or load.

Testing of Lifting gears

No Lifting Machinery and no chain, ring, hook, shackle, swivel, or pulley block shall be used in hoisting or lowering unless it has been tested and examined by a competent person in the manner set out in schedule iv and a certificate of such test and examination in the form approved by the inspector obtained. Whenever a lifting machinery or any component has been lengthened, altered or repaired by welding or otherwise, it shall before being taken in to use for hoisting or lowering, be adequately re-tested and re-examined by a competent person and a fresh certificate obtained

Test and examination of Cargo gear

A record of the particulars of test and examination of lifting appliances, loose gear, and heat treatment shall be entered and maintained in the Chain Register (Form II). Certificates, in the form specified, shall be obtained from a competent person in respect of the following and attached to the Register.

- Initial and periodical test and examination of winches, derricks and their accessory gear – Form III

- Initial and periodical test and examination of cranes or hoists and their accessory gear- Form IV

- Test, examination and re-examination of loose gears – Form V

- . Test and examination of wire ropes – Form VI

- Heat Treatment and examination of loose gears – Form VII

- Annual thorough examination of loose gears – Form VIII

- The register and certificates shall be kept on board the ship and produced on demand to an inspector. They shall be retained for at least five years after the date of the last entry.

Chain Register Form II

The Register (Form II) contains the following parts:

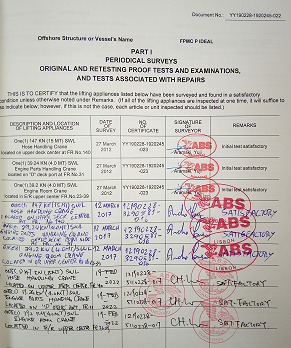

Part I – Initial and periodical load test of lifting appliances and their annual thorough examinations.

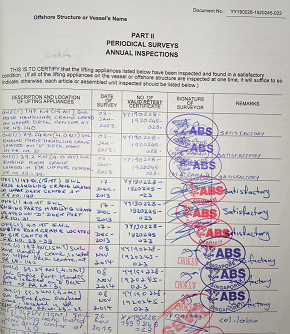

Part II – Initial and periodical load test of loose gears and annual thorough examinations.

Part III- Annealing of chains, Rings, Hooks, Shackles and Swivels (Other than those exempted).

No lifting appliance or loose gear, shall be used for dock work unless the entries required to be made in the register and the certificates of test and examination required to be attached are done.

Annealing

- Heat treatment of loose gears. –

All chains other than bridle chains attached to derricks on mass and all rings, hooks, shackles and swivels used in hoisting or lowering shall, unless they have been subjected to such treatment as an Inspector may, subject to confirmation by the Chief Inspector approve, be effectively annealed under supervision of a competent person and at the following intervals:

a) 12.5 milimetre and smaller chains, rings, hooks, shackles and swivels in general use, once at least in every six months; and

(b) all other chains, rings, hooks, shackles and swivels in general use, once at least in every twelve months:

Provided that in the case of such gear used solely on cranes and other hoisting appliances worked by hand twelve months shall be substituted for six months in sub-clause (a) and two years for twelve months in sub-clause- (b)

(b):Provided further that where an Inspector is of the opinion that owing, to the size, design material or frequency of use of any such gear or class of such gear, the requirements of this regulation as to annealing is not necessary for the protection of dock workers, he may by certificate in writing (which he may at his discretion revoke) and subject to confirmation by the Chief Inspector exempt such gear or class of gear from such requirement subject to such conditions as may be specified in such certificate.

Purpose and Procedures for making entries in Chain Register

Initial Examination and Certification

- 1.1. Every lifting appliance shall be certified by a competent person before being taken into use for the first time to ensure that it is of good design and construction and of adequate strength for the purpose for which it is intended.

- 1.2. Before being taken into use for the first time, a competent person shall supervise and witness testing, and shall thoroughly examine every lifting appliance.

- 1.3. Every item of loose gear shall, before being taken into use for the first time, shall be tested, thoroughly examined and certified by a competent person, in accordance with national law or regulations.

- 1.4. Upon satisfactory completion of the procedures indicated above, the competent person shall complete and issue the Register of lifting appliances and attach the appropriate certificates. An entry shall be made in part I of the Register

- 1.5. A rigging plan showing the arrangement of lifting appliances shall be provided. In the case of derricks and derrick cranes, the rigging should show at least the following information:

- (a) The position of guys;

- (b) The resultant force on blocks, guys, wire ropes and booms;

- (c) The position of blocks;

- (d) The identification mark of individual items; and

- (e) Arrangements and working range of union purchase.

Periodic Examination and Re-testing

- 2.1. All lifting appliances and every item of loose gear shall be thoroughly examined by a competent person at least once in every twelve months. The particulars of these thorough examinations shall be entered in part I of the Register.

- 2.2. Re-testing and thorough examination of all lifting appliances and every item of loose gear is to be carried out:

- (a) after any substantial alteration or renewal, or after repair to any stress bearing part, and

- (b) in the case of lifting appliances, at least once in every five years.

- 2.3. The retesting referred to in paragraph 2.2(a) may be omitted provided the part which has been renewed or repaired is subjected by separate test, to the same stress as would be imposed on it if it had been tested in-situ during the testing of the lifting appliance.

- 2.4. The thorough examinations and tests referred to in paragraph 2.2. are to be entered in part I of the Register.

- 2.5. No new item of loose gear shall be manufactured of wrought iron. Heat treatment of any existing wrought iron components should be carried out to the satisfaction of the competent person. No heat treatment should be applied to any item of loose gear unless the treatment is in accordance with the manufacturer’s instruction; and to the satisfaction of the competent person. Any heat treatment and the associated examination are to be recorded by the competent person in part III of the Register.

Inspections

- Regular visual inspections of every item of loose gear shall be carried out by a responsible person before use. A record of these regular inspections is to be entered in part II of the Register, but entries need only be made when the inspection has indicated a defect in the item.

- Certificates

- The certification forms to be used in conjunction with this Register (Form No. 1) are as follows:

- Form No. 2)–Certificate of test and thorough examination of lifting appliance.

- (Form No. 2(U))–Certificate of test and thorough examination of derricks used in union purchase.

- (Form No. 3)–Certificate of test and thorough examination of loose gear.

- (Form No. 4)–Certificate of test and thorough examination of wire rope.

Procedure for testing derricks

Before testing derricks and cranes, especially heavy lifts, the competent person must ascertain that the stability of the ship is adequate.

A derrick shall be tested with its boom at the minimum angle to the horizontal for which it is designed (generally 15 Deg) or at such greater angle as may be agreed to . This angle shall be mentioned in the test certificate.

The test load shall be applied by movable weights. During the test, the boom shall be swung, with the test load suspended as far as practicable in both directions (P & S).

A derrick boom designed to be raised under power with the load suspended (swinging derrick) shall be raised to its maximum working angle to the horizontal with the load suspended and swung to the two outermost positions in addition to the test mentioned above.

For derricks used in in the Union purchase system, the SWL in union purchase rig must be specified by a competent person in Form III and marked on derrick boom. The two gin falls must be coupled together by a suitable swivel assembly and the derricks tested at their approved working positions with a test load appropriate to the SWL in union purchase.

Procedure for testing Cranes

- Cranes shall be tested similarly to swinging derricks with movable weights at maximum, minimum and intermediate radius points as well as such points in the arc of rotation as the competent person may decide. The test shall consist of hoisting, lowering, braking and swinging through all positions and operations normally performed. All limit switches and cut-off will be tested. Additionally, the machinery shall be tested by operating it at maximum working speed with the SWL suspended.

- After being tested, every lifting appliance and loose gear shall be thoroughly examined to see that no part has been damaged or permanently deformed during the test.