Small spills can occur during routine transfer operations on the ship, i.e. during loading, discharging, ballasting, bunkering etc. If an oil spill occurs at any time, the Ship’s Oil Spill Emergency Plan (SOPEP) must immediately be put into operation.

Responsibilities

The responsibilities of shipboard officers are clearly laid down in the company’s regulations but may be summarised as follows.

During any loading, transferring or discharging of cargo, tank cleaning or ballasting and when bunkering, the Master or Chief Officer and the Chief Engineer or Second Engineer must be on board. During these operations at least one deck officer and engineer must be on duty.

Preventative Measures

The prevention of oil spills must be regarded as a high priority in any oil transfer operation. The most commonly recorded causes of operational spills are cargo and bunker overflows, pipeline leakage including COW lines, leakage from overboard and sea valves, the accidental discharge of dirty ballast and lastly, oil spray from tank vents and common vapour risers. In addition, direct leakage from the ship’s hull is an occasional cause of minor spillages. Measures adopted to prevent these occurrences are fully described in the International Safety Guide for Oil Tankers and Terminals (ISGOTT),and include specific items on the Ship/Shore Safety Checklist.

If, despite the adherence to proper procedures, an oil spill does occur, all cargo and bunker operations should be stopped by the quickest possible means and should not be restarted until the source of the leak has been identified, rectified and all hazards from the oil released have been eliminated. In most cases, the cause of the leak will be obvious but, in some instances, such as spillages resulting from slight hull leakage, the source may be difficult to locate, requiring the services of a diver.

The duty officer assisted by the duty watchman should undertake the following actions in the event of an incident. He should also inform the Master, chief officer and the Chief Engineer to facilitate the mobilisation of additional manpower as required and to initiate notification procedures.

Tank Overflow

Should a tank overflow occur, the flow to the tank should be stopped immediately and the level in the tank lowered by the most practical means.

Pipeline Leakage

Should leakage occur from the ship’s on-deck pipework or from transfer hoses, the cargo operation should be stopped immediately and pressure relieved from the leaking section of line. The line content may be dropped or, if necessary, pumped into an empty or slack tank.

Overboard and Sea Valves Leakage

Should leakage from an overboard or sea valve occur, the cargo operation should be stopped immediately and the pressure relieved from the relevant sections of line.

Oil Spray from Tank Vents and Common Vapour Risers

Should an oil spray occur from tank vents/mast risers, the cargo flow should be stopped and the vent/riser shut and allowed to drain. The cause of the oil entrainment in the vapour flow should be established and the necessary measures taken to prevent recurrence.

Hull Leakage

Should spillage be suspected due to hull leakage, measures should be taken to reduce the head of cargo in the tank involved, either by internal transfer, listing/trimming the ship or discharge ashore. Unless timely corrective action is taken, oil will continue to leak to the sea until a hydrostatic balance is achieved between the head of oil remaining in the tank and the sea water pressure exerted on the hull. Should it not be possible to identify the specific tank from which leakage is occurring, the levels of all tanks in the vicinity should be reduced, taking into account the effect on hull stress and stability.

Should it be suspected that leakage is from a fracture in the bottom plating or lower shell plating, consideration should be given to reducing the level in the tank, if full, and then pumping a water bottom into the damaged tank to prevent any further oil spillage.

Containment on Board

In the event of an oil spill on deck, the following steps should be taken to prevent or minimise overside pollution utilising the on board spill equipment.

a) Identify the source and stop the leak.

b) Place drip trays or containers to catch the leakage.

c) Bail or pump pools of oil into tanks, drip trays or containers.

d) Soak up the oil with absorbent material form the SOPEP kit.

e) Ensure scupper plugs are tight and any excess water is drained off.

f) List/trim the ship to maintain/increase the deck scupper volume.

The prevention of overside pollution and its mitigation takes precedence over cargo quality and contamination concerns.

Oil Leakage/Overflow During Loading

a) Contact the terminal and request to stop loading immediately. Cease all cargo and ballast operations.

b) Follow the individual terminal emergency stop procedures and signals.

c) Manifold valves may be closed only after permission is received from the terminal.

d) In case of overflow, open valves to any empty/slack tanks to reduce the level of the overflowing tank.

e) Sound the General Emergency Alarm with a PA broadcast and muster the oil spill emergency reponse team.

f) Check/stop the air intake to accommodation, stop non-essential air intakes to the engine room.

g) Close all non-essential sea suctions.

h) Re-check that all scuppers are shut.

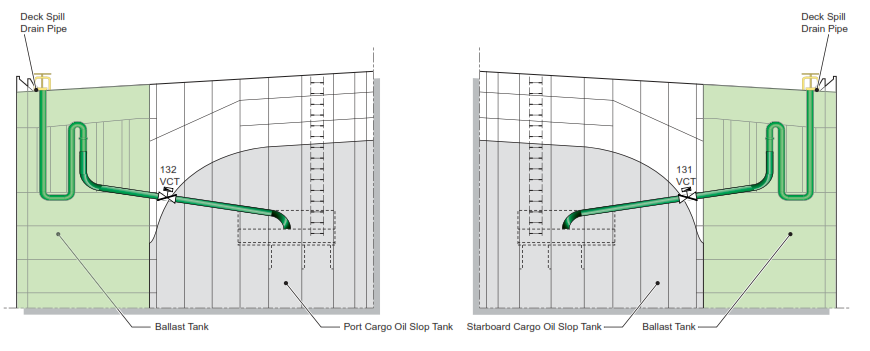

i) Contain the spill on board by opening the main deck drain valve leading directly to either the port or starboard slop tank, or by using a Wilden pump which can discharge into either the port or starboard slop tank.

j) Deck clean up is to be started and fire fighting equipment to be kept ready for use.

k) Oil spill dispersants/emulsifiers should never be used overside except for small spills where written approval is received from the appropriate authorities.

l) Reporting procedures to be followed as per the SOPEP/VRPdepending on the location of the ship.

m) Loading may be resumed after the fault has been rectified.

Oil Leakage/Overflow During Cargo Handling

Should an oil spill occur during cargo handling, the following actions should be followed:

a) Stop/trip the cargo pumps immediately. Cease all cargo and ballast operations.

b) Inform the terminal about the nature and extent of the leak.

c) Sound the General Emergency Alarm with a PA broadcast and muster the oil spill emergency reponse team.

d) The manifold valves may be closed.

e) Identify and isolate the leaking section of the line if possible.

f) Open the drop valves to drain the top lines and consider reducing the IG pressure in the tanks.

g) Check/stop the air intake to the accommodation. Stop nonessentialair intakes to the engine room.

h) Close all non-essential sea suctions.

i) Re-check that all scuppers are shut.

j) Contain the spill on board by opening the main deck drain valve leading directly to either the port or starboard slop tank, or by using the a Wilden pump to discharge into the port or starboardslop tank.

k) Deck clean up is to be started and fire fighting equipment to be kept ready for use.

l) Oil spill dispersants/emulsifiers should never be used overside except for small spills where written approval is received from the appropriate authorities.

m) Reporting procedures to be followed as per the SOPEP/VRP depending on the location of the ship.

n) Discharging may be resumed after the fault has been rectified.