The burning of any fuel onboard ship, creates exhaust gases or emissions and most of these have an effect on the environment.

The quality of the fuel oil being burnt influences the level and type of emission, however, cylinder lubricating oil also produces emissions as it is a hydrocarbon and contains chemical additives.

Some of the components from exhaust gas are:

- Toxic to human health and environment

- Produce acid rain

- Produce greenhouse effect

Therefore these are hazardous to environment and are required to be effectively controlled as prescribed in Marpol Annex VI.

Marpol Annex VI

- Sets limits on sulhur dioxide and nitrogen oxide emmisions from ship exhausts.

- Sets standards for quality of fuel and accompanying bunker delivery note stating fuel quality.

- Prohibits deliberate emissions of ozone depleting substances for Sox, NOx and Particulate matter (PM)

- Technical and operational energy efficiency measures which will significantly reduce the amount of greenhouse gas emissions from ships.

Application of MARPOL Annex VI

Marpol annex VI is applicable to all ships of 400 gross tons and above which have to carry an International Air Pollution Prevention Certificate (IAPP Certificate)

Regulations of MARPOL Annex VI

Under Marpol Annex VI has provisions (regulations) that deal with measures taken for prevention of air pollution from ships.

Some of the relevant regulations include:

Regulation 12–

Prohibits the use or release of ozone depleting substances (ODS).

Regulation 13–

Restricts NOx emissions from diesel engines.

Regulation 14–

Restricts SOx emissions from ships by introducing a maximum sulphur content in marine fuels. In addition, MARPOL Annex VI identifies SOx emission control areas (SECA).

Regulation 15–

States that in ports where there is a need to control the emission of VOCs (Volatile Organic Compound), there is also a requirement for the ports to ensure appropriate recovery facilities are available.

Regulation 16 –

Prohibits the incineration of certain substances, including; PCBs, garbage containing traces of heavy metals, refined petroleum products containing halogen compounds and residues from MARPOL Annex I, II and III cargoes.

Regulation 17-

Reception Facilities for ozone-depleting substances (ODS) and Exhaust Gas Cleaning System residues.

Regulation 18–

Quality of Fuel oil and bunker delivery note (BDN) stating the fuel quality including sulphur content among other information

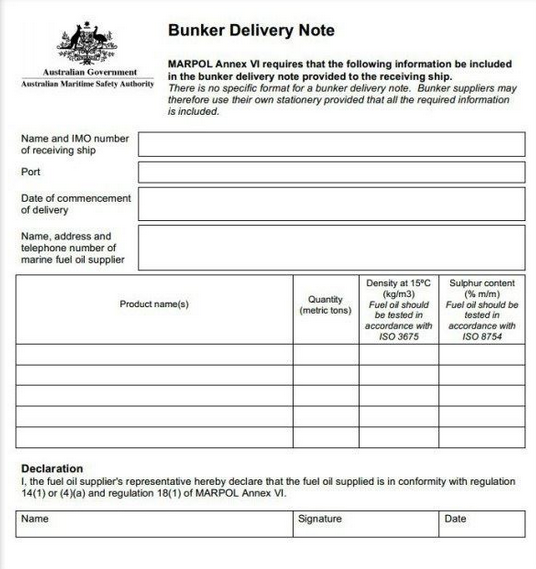

Bunker Delivery Note

- Bunker delivery note is to record agreement on the operational details of the transfer and to ensure safe transfer of the product.

- This document originates from the seller’s representative and states the grade or grades with the nominated quantity.

- Agreement should be reached on the witnessing of a representative sample and this again is detailed later. The spill prevention transfer procedure must also be discussed and agreed.

Contents of bunker delivery note (BDN)

MARPOL Annex VI requires that the following information be included in the bunker deliver note provided to the receiving ship:

- Name and IMO number of receiving ship

- Port

- Date of commencement of delivery

- Name, address and telephone number of marine fuel oil supplier

- Product name

- Quantity (metric tons)

- Density at 15°C (kg/m³)

- Sulphur content (% m/m)

- A declaration signed and certified by the fuel oil supplier representative that the fuel oil supplied is in conformity with regulation 14(1) and regulation 18(1) of annex VI.

Key steps for sampling fuel during bunkering operations

Inspect sampling equipment and ensure that it is clean

Ensure sampling starts simultaneously with the bunkering operation

Check a continuous drip sample is taken throughout the operation

After bunkering, confirm the seals of the sampling container and the needle valve are not tampered with

Check sample labels include all relevant information before signing

Check and ensure tht cargo officer performs a number of detailed steps, such as sealing the samples and recording the seal number in the bunker delivery note.

Energy Efficiency Regulation

The three key requirements of the regulations are:

- Energy efficiency deisgn index (EEDI)

- Ship energy efficiency management plan (SEEMP)

- International energy efficiency certificate (IEEC)

The energy efficiency aims to promote energy efficient and less polluting (Sox, NOx, CO, CO2 etc) operation of ships by better design, equipment and operational procedures.

Emission Pollutants

Sources of emission of harmful gases from ships which are covered under MARPOL Annex VI include:

a. Ozone depleting substances e.g. refrigerant gases(CFCS), Halons

b. Gases which may cause acid rain e.g. SOx and NOx from main engine fuel after combustion

c. Volatile organic compound

d. Exhaust gases from shipboard incinerators

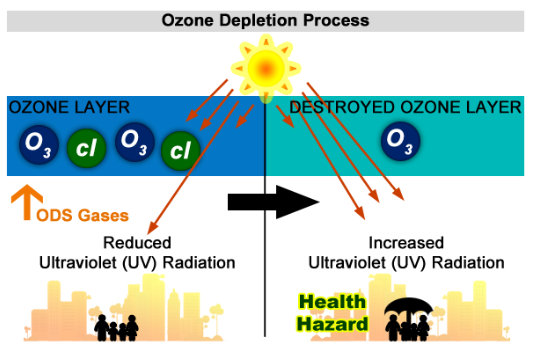

- Ozone depleting substances(ODS) comprise of:

(i) Refrigerant gases which contain CFC(Chlorofluorocarbons) used in refrigeration and air conditioning system,

(ii) Halongases used in fire fighting systems

(iii) Solvents for cleaning

Ozone depleting substances (ODS) are man – made gases that destroy ozone once they reach the ozone layer.

The ozone layer sits in the upper atmosphere and reduces the amount of harmful ultraviolet (UV) radiation that reaches Earth from the sun.

Ultraviolet radiation can have detrimental effects on both humans and the environment such as inducing skin cancer and cataracts, distorting plant growth and damaging the marine environment.

2. “Acid rain” caused by emission gases;

The main chemicals in air pollution that create acid rain are sulfur dioxide (SO2) and nitrogen oxide (NOx).

Acid rain usually forms high in the clouds where sulfur dioxide and nitrogen oxides react with water, oxygen, and oxidants. this mixture forms a mild solution of sulfuric acid and nitric acid.

Health hazard of emission gases – for e.g., Sox (originating from the sulphur content of main engine fuel) and NOX (originating due to mixing up of N2 and O2 at high temperatures of the engine exhaust)

Through chemical reactions in the air, SO2 and NOx is converted into very small airborne particles, sulphate and nitrate aerosols . Tiny airborne particles are linked to premature deaths.

The particles get into the lungs and are small enough to pass through tissues and enter the blood. They can then trigger inflammations which eventually cause heart and lung failures. Ship emissions may also contain carcinogenic particles

3. Volatile organic compounds(vocs) ; for e.g., emission of tank atmosphere from tankers during loading exhaust gases from ’shipboard incinerators’.

During loading and discharging of oil cargo a large quantity of lighter components evaporate from the oil. These oil vapours are technically called Volatile Organic Compounds (VOC), which are explosive in nature and contain greenhouse gases such as methane.

Since the generation of oil vapour will also lead to increase in the tank pressure, the cargo oil storage tanks are provided with vent pipes to discharge VOC to the atmosphere causing air pollution

4. Exhaust gases from shipboard incinerators

Incinerator means a shipboard facility designed for the primary purpose of incinerating solid waste generated during the operation of the ship.

E.g. waste oil, oil and water mixtures, rags, galley waste etc., and sewage sludge.

Following waste must not be incinerated

- oil cargo residues, noxious liquid substance cargo residues and marine pollutants;

- polychlorinated biphenyls (PCB),

- garbage containing more than traces of heavy metals;

- refined petroleum products containing halogen compounds;

- sewage sludge and sludge oil that are not generated on board the vessel; and

- exhaust gas cleaning system residues.

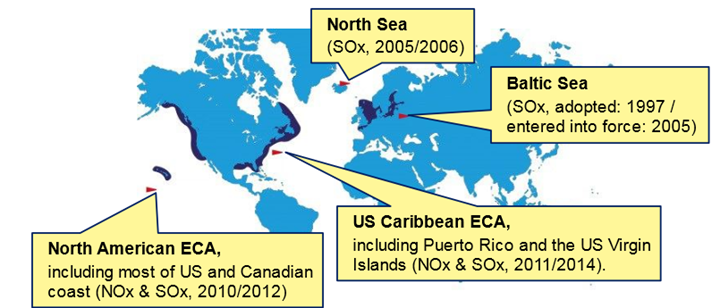

Emission control areas

Two sets of emission and fuel quality requirements are defined by annex VI:

- Global requirements

- More stringent requirements applicable to ships in Emission Control Areas (ECA)

Existing Emission Control Areas include:

In Emission control areas (ECA) ships are allowed to burn only fuel with much lower sulhur content to limit Sox and Particulate matter (PM) emission.

Maximum Sulphur content of marine fuel consumed by the ships:

IMO-ECA-SECA :- 0.1%

IMO-Global (Outside ECA) :- 0.5%

How can ships meet lower Sulphur emission standards

- Using gas as a fuel which leads to negligible sulphur oxide emissions

- Using low suplhur fuel (0.5% Sulphur Global and 0.1% Sulphur in Emission Control Area (ECA))

- Using exhaust gas cleaning systems or scrubbers which clean the emissions before they are released into the atmosphere.

Greenhouse Gas Emissions

Regulations on energy efficiency for ships

- The energy efficiency design index (EEDI) for new ships

- The ship energy efficiency management plan (SEEMP) for all ships

The EEDI is a performance based mechanism that required a certain minimum energy efficiency in new ships. Ship designers and builders are free to choose the technologies to satisfy the EEDI requirements in a specific ship design.

The SEEMP establishes a mechanism for operators to improve the energy efficiency of ships.

Compliance

Compliance with the provisions of Annex VI is determined by periodic inspection and surveys.

Upon passing the surveys the ship is issued an “International Air Pollution prevention certificate” which is valid for 5 years

Under the “NOx technical code” the ship operator is responsible for in use compliance.

IMO has issued guidance to ensure compliance to MARPOL Annex VI, it includes:

Document Checks:

- International air pollution prevention certificate and its supplement

- Bunker delivery note

- EGCS approved documents (ie SECP, OMM, ETM, SECC)

- Check record book

Ship is detainable if

- Invalid/ Absence of valid IAPP certificate

- Non-compliant fuel is used and carried for use when there is no reporting of FONAR or the ship is not fitted with EGCS

- Absence of appropriate approval for the EGCS

- Ship crew is not familiar with the essential operation of EGCS.

Physical inspection

- Check if compliant fuel oil is in use (ie sampling)

- Check EGCS operational records

- Check if the EGCS monitoring equipment is functional

- Check if the crew is familiar with the function of the EGCS.