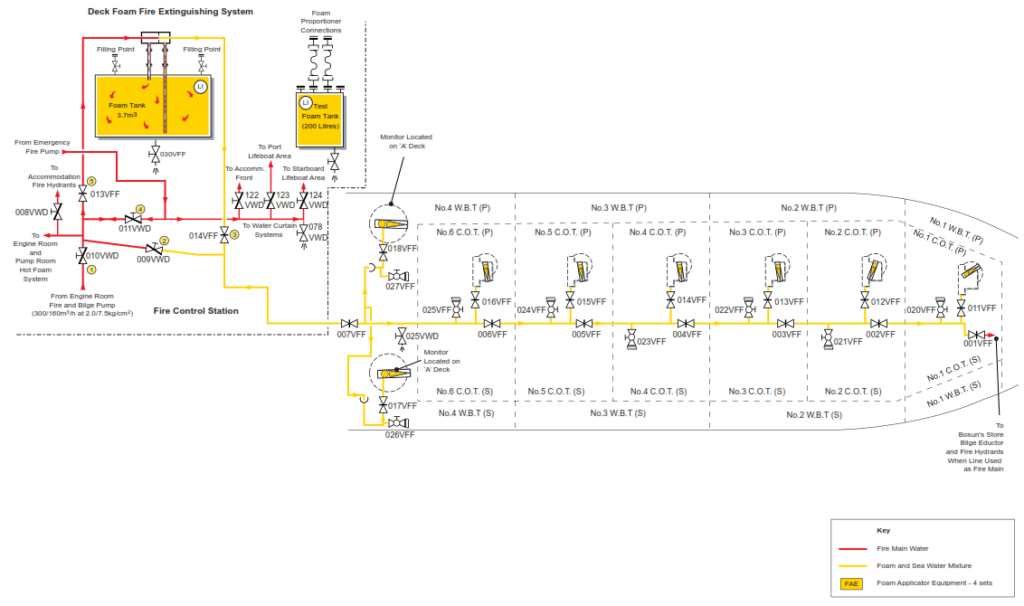

The foam system supplies foam to eight monitors at various points on upper deck. The liquid foam making chemical is stored in a 3.7m3 tank located inside the hydraulic pump unit, foam tank room and fire control station in side accommodation on the upper deck.

The foam is made by discharging a portion of the fire main sea water supplied by the fire and bilge pump or the emergency fire pump, into the foam tank. The chemical foam is mixed with the sea water inside the tank and then forced out of the foam tank by a syphon tube into the proportioning eductor. Here it mixes it with the bulk of the fire water supply at a ratio of 3% chemical solution to 97% sea water as the main supply passes through the orifice plate of the proportioner, it is then discharged into the foam/fire main onto deck.

There are eight directable foam monitors which allow foam to be sprayed over the deck area of which two are located just in front of the accommodation block.

In addition to the fixed monitors, four sets of portable foam fire fighting appliances are located adjacent to the foam supply tank. The portable branch pipes and a fire hose can be connected to a fire/foam hydrant point.

During normal service the five foam main isolating valves along the upper deck would be left open. The foam tank valves ( (a) Foam eductor inlet (b) foam eductor outlet (c) Fire pump discharge direct to fire main) are normally left in the closed position when the system is not is use.

Procedure for Making the Foam System Operational

a) Inspect the level sight glass to ensure that there is sufficient foam chemical in the foam tank.

b) Check that the fire/foam main isolating valves on deck are all open, these valves are normally left in the open position.

Procedure for Operating the Foam System from the Fire Control Station

a) Start the fire and bilge pump or the emergency fire pump as required from the starter panels in the fire control station. When starting the emergency fire pump, ensure that the suction valve for the pump is opened by using the valve open selection button. The discharge onto the fire main from the emergency fire pump,

b) Ensure that the fire main pressure is at 0.6MPa before operating the following valves.

| Position | Description |

| Open | Foam eductor inlet valve |

| Open | Foam eductor outlet valve |

| Closed | Fire pump discharge direct to the fire main |

c) Open the monitor and hydrant valves nearest to the fire as required. If a manual foam applicator is to be used it should be connected before the hydrant valve is opened.

d) The system is at its optimum with one monitor and two portable applicators in use. Should it be necessary to use more than this, the effectiveness of the system will be reduced.

e) Check that foam is issuing from the monitor and applicator so that the foam can be sprayed where it is required.

WARNING:- The discharge from the monitors should not be directed at the fire until foam begins to issue from the nozzle(s). The foam should be directed so that it spreads over the surface of the burning oil and gradually smothers the fire. The foam should not be aimed directly at the oil in case it causes it to splash and spread. Also use the prevailing wind and slope of the deck to assist in creating a blanket whenever possible.

Procedure for Cleaning and Preparing the Foam System

After the foam system has been used the remaining contents of the foam tank must be changed and replaced with a new charge of foam compound.

a) After finishing with the deck foam system stop the emergency fire pump or the fire and bilge pump.

b) Close the inlet and outlet valves on the foam tank, then open the tank drain valve to drain the contents.

c) With the drain valve closed, reopen the inlet and outlet valves on the foam tank and restart the duty fire pump. Flush through the tank. Open the forward monitor on the main deck then operate all other monitors and hydrants for a few seconds to clear foam residues from the lines.

d) Wait until only clean sea water is discharged from the foam tank and then stop the duty fire pump. Drain the tank of sea water.

e) Stop the fire and bilge/emergency fire pump(s).

f) Revert all valves to their standby positions.

g) Refill the foam tank as soon as possible, ensure no sea water remains inside the tank before it is recharged.