Why stowage plays a important role for cargo handling???

We will discuss the principles of stowage of some important general cargoes.

Stowage of bags

The dunnage must be first laid on the tank top. It should be laid fore and aft if there are drain wells at the after ends. The second tier of dunnage should be at right angles to the first tier. If the bags contain coffee, beans or other commodity that may spill from the bags, a separation cloth (usually burlap) is laid and bags are loaded on top of this cloth, so that, these sweepings could be collected and discharged.

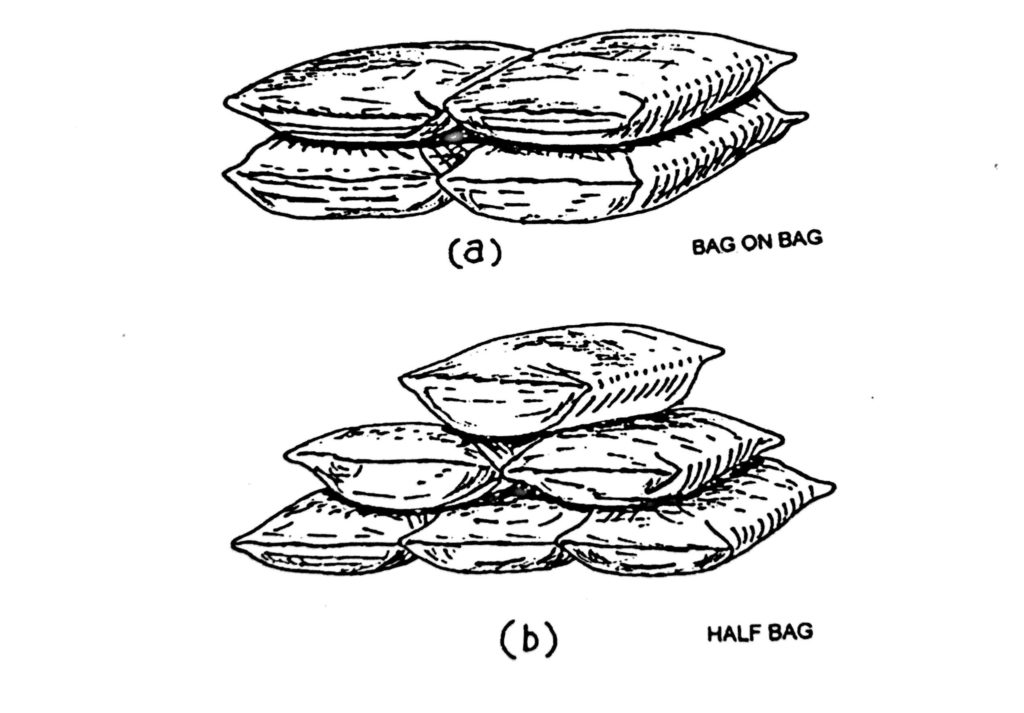

The bags could be stowed in three different ways, depending on the commodity. If it requires maximum ventilation, the best stowage is one bag directly on top of the one below, laid with length fore and aft. This stowage will provide small air spaces throughout the stowed cargo and help in circulation of air. This manner of loading is called “bag on bag.”

If the cargo does not require maximum ventilation, the best way is to place the upper bag between two lower ones. This stowage eliminates the spaces between rows and tiers and reduces broken stowage. This type of stowage is called “half bag” stowage.

When stowing bagged cargo in small blocks in which stability of the block is a problem, it is advisable to stow one tier of bags fore and aft and next tier athwart ships. This type of stowage ties the tiers together, so that, the block is less likely to fall over while working the cargo in Port or when ship is rolling. These blocks should also be shored up or blocked by other cargo.

Stowage of bales

Dunnage

Dunnage must be laid as for bags. Bales contain either unprocessed fibre or strands of material shipped in layers, e.g. cotton piece goods, tobacco, skins and dry goods. Bales are generally placed on their flats, edges or crowns. No damage will be caused due to such placement. They stow more securely. It is important to measure hold clearance vertically. Arrange stow, so that, the top of the last tier will be as close as possible to the underside of the beams.

Do you know?

If the contents of the bale are in layers, the bales in the first tier are laid down on the dunnage platforms on their flats. The outboard bales in each tier should be placed on their edges, so that, their flats will be presented to the sweat batten / cargo batten. This precaution is necessary to minimise the damage in case of Chafage. If the bales chafe or become wet on their flats, only one of two layers will be damaged. If the edges or ends are damaged, every layer in the bale will be damaged. Some of the fibrous commodities may present a danger of fire due to spontaneous heating resulting in spontaneous combustion. You must make sure that the bales are dry and free from oil stain. Secondly, you must ensure that dunnage always stands between a bale and metal parts of ship.

Stowage of cartons

Dunnage shall be laid as for loading of bags. The loading may start at the centre line and proceed out board or vice-versa. However, it is very important that during the stowage of cartons, the level should be maintained in the wings. As the stowage proceeds Outboard from the centre you should make sure that no carton is stowed beyond the level of the carton at the lowest tier.

This will leave a triangular void portion at the Outboard end. This void should be plugged with the dunnage. The loading of the cartons should be done in the brick fashion I.e. one carton is loaded on top of the other cartons. Vertical dunnage must be placed to prevent the cartons from getting out through the sweat battens/cargo battens.

Stowage of cases

Cargoes packed in Wooden boxes are called cases. They may contain a variety of items, viz., machinery, foodstuff, beverages etc., uniform sized cases may be loaded in the brick fashion.

Watch it!!!

When the length of the case is twice the breadth, the safety of the block stowage is ensured by arranging one tier fore and aft and the next tier athwartship.

Stowage of barrels

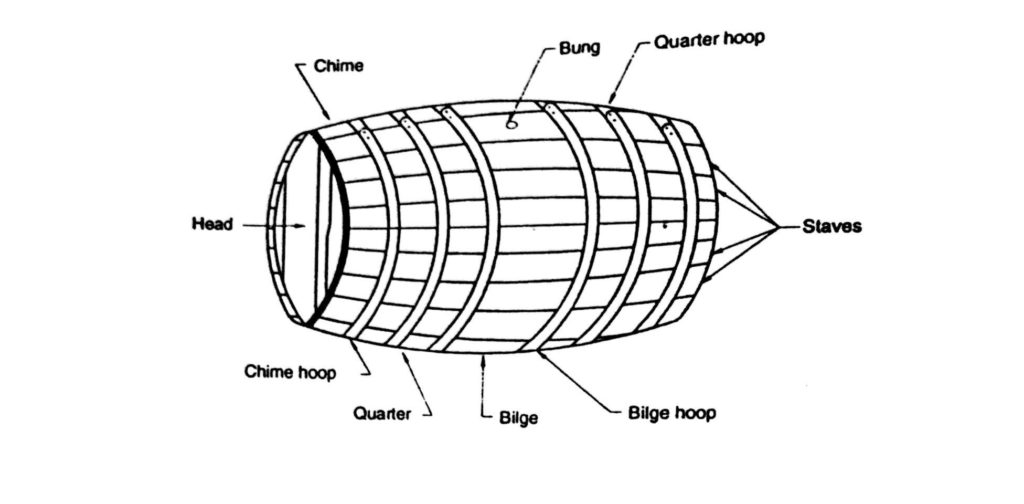

Barrels refer to all type of containers of cask type. The volumes of barrels are not universal. The ‘barrels’ used in petroleum industry has a volume of 42 gallons. There are two broad categories of casks; the wet or tight cask made of oak, which is used to ship beer, wine, spirit and olives. Nowadays, aluminium casks are generally used instead of wooden casks.

The weakest part of the cask, whether aluminium or wooden is the “bilge of the cask.” The strongest part is the quarter.

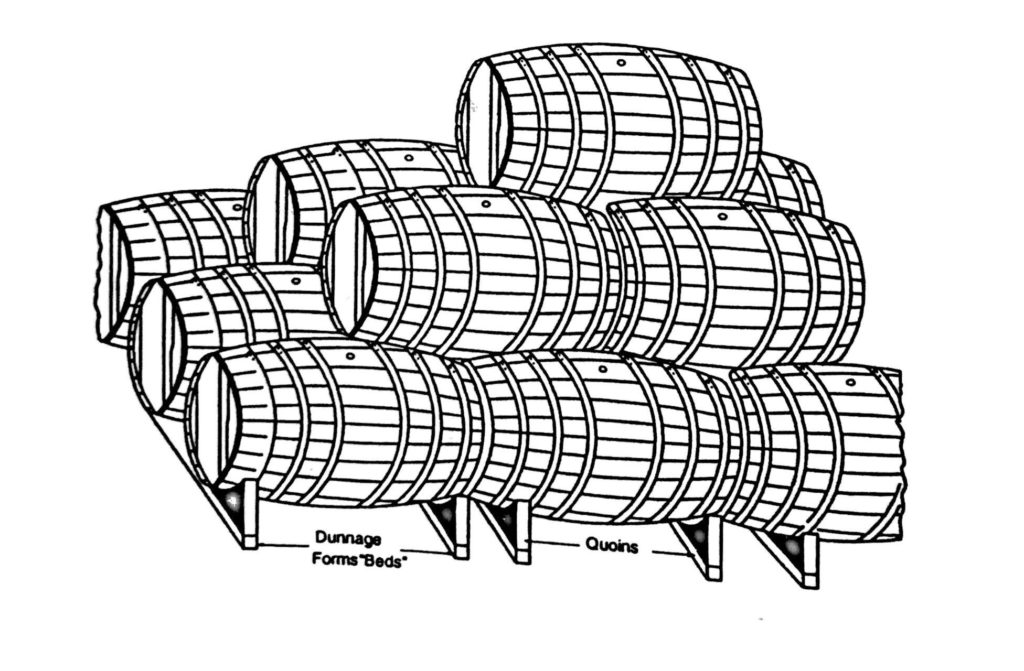

The quoins are chocks or supports which fit the curvature of the cask at the quarters and raise the cask vertically to clear the bilge from the deck. This type of storage is called bilge storage.

In the wings, care must be taken to wedge the outboard cask securely with the dunnage. Dunnage is not required between the first and the second tier. Before stowing third tier, dunnage should be placed in the space between bulkhead and the chime of the second cask as shown in the below figure.

Stowage of Cylinders

Compressed gases, flammable as well as non-flammable, are shipped in steel bottles usually called cylinders. These must be handled carefully and stored securely to avoid accidents.

Stowage of drums

Drums must be stowed directly on the deck. However, at least a single layer of the dunnage provides and offers more friction to prevent slipping of drums in heavy rolling. In the wings, plenty of dunnage should be used to fill in the space left between the last outboard drum and the ship’s side.

Important

The maximum number of tiers that can be placed depends upon the load density of tank top and stowage factor of the cargo.

Stowage of coiled sheet steel

These should be given bottom stowage and should be stowed in regular tiers from side to side in the hold. These coils should be stored on the dunnage laid athwartship and their axis fore and aft direction. Each coil should be stowed close against its neighbour.

Wedges should be used as stoppers when necessary, to prevent slipping. The final coil in each row should normally rest on two adjacent coils. The mass of this coil will lock the other coils in the row.

If it is necessary to load a second tier over the first, the coils should be stowed in between the coils. Any void space between the coils in the top most tiers should be adequately secured.

Stowage of the deck cargoes

Cargoes that cannot fit into the lower holds because of their size, nature or because of its dangerous characteristics are loaded on the deck. The main factors that you should consider when loading on the deck are:

▬ Safety of the cargo

▬ Accessibility of equipment needed to operate the vessel safely and

▬ Stability of the vessel

Safety of the deck cargo begins with making advance plans regarding lashing and securing of cargo, the location of deck pad eyes, the side from which weather is expected etc. After checking these details, the stowage is to be decided. At times when the deck pad eyes are not sufficient, additional ones could be welded on deck.

Keeping the equipment accessible is a matter of ensuring that all items such as bilge sounding pipes, cleats, fair leads, bits, hydrants, fire hose racks, access to forecastle etc. are clear. As you are aware, when loading deck cargo, the metacentric height of the vessel reduces. Calculations have to be made to ensure that the vessel will be stable at all times.

Stowage of bulk grain

Grain loaded in bags does not offer any.special problems. Grain in bulk is dangerous during transportation, due to possibility of its shifting and thereby rendering the ship unseaworthy. Carriage of grain is therefore subject to stringent International Regulations. These regulations require the vessel to calculate the effects of an assumed shift of the grain on the stability of the vessel.

If the planned stowage is such that the effect of assumed shift is within the parameters of the regulations, the vessel may sail without any further expensive securing of the grain.

A case study

Here, I recall an incident where though the stowage was done correctly; it led to an unsafe situation. Steel plates and vegetable oil drums were loaded for the same Port.

Steel plates are very difficult to secure and if not secured properly, will shift with disastrous consequences. The best way is to over stow them with other cargo. We loaded steel plates in the lower hold and these were over stowed with vegetable oil drums. There is no Compatibility problem between steel plates and vegetable oil. The drums were properly lashed and the stowage was perfect. The vessel reached discharge Port and all cargo was intact. The vegetable oil drums were discharged.

After that, shore gangs commenced discharging steel plates. However, during discharge of the vegetable oil drums, there was some leak from the drums and that had made the steel plates very slippery: Despite best attempt to wipe the steel plates clean, the labourers were slipping and falling. In fact, one steel plate itself slipped from the lifting clamps and fell on the tank top, piercing it!