•Timber – means sawn wood or lumber, cants, logs, poles, pulpwood and all other types of timber in loose packaged forms but not including wood pulp or similar cargo.

•Cant – means a log that is cut in slabs, so that two opposite or sometimes three sides are flat and the other(s) curved.

•Timber Deck cargo means a cargo of timber carried on an uncovered part of the freeboard or superstructure deck. It does not include wood pulp or similar cargo.

•Timber load line -means a special load line assigned to ship which comply with certain regulations of the International convention of loadlines regarding construction of the ship and stowage and securing of cargo.

•Weather deck- means the uppermost continuous deck exposed to weather and sea.

•Fall protection system- means a system having an adequate anchorage point, a safety harness, to be worn and a fall arrest device which locks when any force is applied to the system.

(Fall protection is defined as a planned system used to protect a worker from death or potential injury in the event they would lose their balance while performing a task at height.)

Application and Stability information

•The code applies to all ships of 24m or more in length when carrying timber deck cargoes.

•Stability of the ship at all times should be positive as per the criteria taking into account:

a.Increased wt of timber due to absorption of water and ice accretion.

b.Variations in consumption of fuel and freshwater.

c.Free surface effect of liquids in tanks.

d.Weight of water trapped in broken spaces within the timber deck cargo especially logs.

Stability information to Masters

Comprehensive stability information is to be provided to the master should include;

a.Stability Characteristics for the varying conditions of service i.e Loaded, Ballast arrival departure conditions.

b.Tables or diagrams to assess the stability and initial metacentric height at various drafts to ensure ships comply with stability criteria.

c.Rolling period tables and corrections to be applied for Free surface effect.

d.Changes in the deck cargo when the permeability is significantly different from 25%.

e.Maximum permissible amount of deck cargo.

f.Information on the use of anti-rolling devices if these are fitted on the ship.

The Master should stop all loading operations if a list develops due to unknown reasons and should proceed out to sea in upright condition. The initial GM should be adequate but a large GM will result in rapid and violent motion in heavy seas causing high stresses on the lashings. Recommended that GM should not be > 3% of breadth.

Compliance with stability criteria does not ensure immunity from capsizing or absolve the master of his responsibilities. He should therefore exercise prudence and good seamanship and proceed at a safe speed and course with regard to the season of the year, weather forecasts and area of navigation.

A number of influences such as beam wind on ships, icing of topsides, water trapped on deck, rolling characteristics, following seas, etc. adversely affect the stability of the ship.

Stability Criteria as per IS code 2008

For ships loaded with timber deck cargoes and provided that the cargo extends longitudinally between superstructures – where there is no limiting superstructure at the after end, the timber deck cargo shall extend at least to the after end of the aftermost hatchway), transversely for the full beam of ship, after due allowance for a rounded unwale, not exceeding 4% of the breadth of the ship and/or securing the supporting uprights and which remains securely fixed at large angles of heel may be:

The area under the righting lever curve (GZ curve) shall not be less than 0.08 meter-radians up to ϕ = 40° or the angle of flooding if this angle is less than 40°.

The maximum value of the righting lever (GZ) shall be at least 0.25 m.

At all times during a voyage, the metacentric height GM(0) shall not be less than 0.1 m, taking into account the absorption of water by the deck cargo and/or ice accretion on the exposed surfaces.

When determining the ability of the ship to withstand the combined effects of beam wind and rolling according to wind heeling criterion of IS code 2008, the 16° limiting angle of heel under action of steady wind shall be complied with, but the additional criterion of 80% of the angle of deck edge immersion may be ignored.

Stowage of Timber cargoes

The Principle of safe carriage of timber deck cargo is to make the stow as solid and compact as possible so as to

a.Prevent slack which would cause the lashings to loosen.

b.Produce a binding effect within the stow.

c.Reduce to minimum the permeability of the stow.

Lashings of Timber deck cargoes

Lashings prevent deck cargo from shifting by increasing the friction and counteracting forces acting on the stow. Lashings must be of sufficient strength as recommended in the code and maintained at the necessary tension.

Shifting of Timber deck cargoes

Shifting of timber deck cargoes is due to either one or the following reasons,

a.Insufficient strength of the lashings, slackening of the lashings due to compaction of the cargo or unsuitable devices used for tightening the lashings.

b.Movement of the cargo across the deck or hatch covers due to less friction especially in ice or snow.

c.Failure of the uprights due to less strength or excessive forces.

d.Heavy rolling or pitching of the ship.

e.Impact of heavy seas.

Preparation before loading of timber deck cargoes

1.Hatch covers and other openings to spaces which are not used for the normal working of the ship must be securely closed and battened down.

2.Air pipes, sounding pipes and ventilators should be protected and valves and means of closing checked that they are effective against entry of water.

3.Ice, snow and water should be removed from the deck and hatch tops.

4.Lashing equipment may have to be examined before loading and it is preferable to have these rigged in position before loading on that area.

Precautions during loading

1.Constant supervision by ship’s personnel is necessary to achieve a solid stow at all stages of loading.

2.The ship must be kept upright at all times to prevent unnecessary stress on the uprights and a shift of cargo or unsymmetrical loading.

3.ANNEX A provides Guidance in developing procedures and checklists for the following

a. Preparations before loading of timber deck cargoes.

b. Safety during loading and securing of timber deck cargoes.

c. Securing of timber deck cargoes.

d. Actions to be taken during the voyage.

e. Safety during discharge of timber deck cargoes.

4. The Cargo must be kept free of accumulations of ice and snow.

5. Safe and satisfactory means of access to crew quarters, pilot boarding area, machinery spaces and all other areas used for the necessary working of the ship must be provided at all times.

6. It must be possible to properly close and secure openings to the above areas.

7. Safety equipment, devices for remote operation of valves, emergency steering gear and sounding pipes must be left accessible.

8. After completion of loading and before sailing a thorough inspection of the ship must be made and soundings checked to verify that no damage causing an ingress of water has occurred.

Height of deck Cargo

The Height of the timber deck cargo must be restricted to,

a.Adequate visibility from the navigation bridge must be ensured.

b.A safe margin of stability is maintained at all stages of the voyage.

c.The forward part of the cargo should be slopped so as to not present a resistant wall to head seas.

d.The load density of the deck and hatches is not exceeded taking in to account the possibility of ice accretion / moisture absorption by the cargo.

e.On a ship in a seasonal winter zone in winter, the height does not exceed 1/3 the extreme breadth.

f.The height should be to at least the standard height of a superstructure other than a raised quarter deck.

Extent of Timber Deck Cargo

•The timber Deck cargo should be stowed so as to extend;

1.The full available length between superstructures or wells and as close as possible to the end bulkheads.

2.To the aftermost end of the aftermost hatchway where there is no limiting superstructure at the after end.

3.Athwartships as close as possible to the shipside, after making allowances for the obstructions such as guard rails, bulwark stays, uprights, pilot boarding access, etc., provided the broken stowage thus created does not exceed a mean of 4% of the breadth.

Securing and lashing of Timber Deck cargo

1.Every lashing should be shackled to adequate eye plates which are efficiently attached to the deck stringer plate or other strengthened points. They should pass over the timber deck cargo in such a way, as to be as far as practicable, in contact with the cargo throughout its height.

2.All lashings and components used for securing should:

a.Have a breaking strength of not less than 133 Kn.

b.Show no permanent deformation after being subjected to a proof load of 40% of the breaking strength.

c.Show an elongation of not more than 5% at 80% of their breaking strength.

3. Tightening devices must be placed where they can be safely and efficiently operated when required. They should be capable of producing a load of not less than 27kN in the horizontal part of the lashing and 16kN in vertical part.

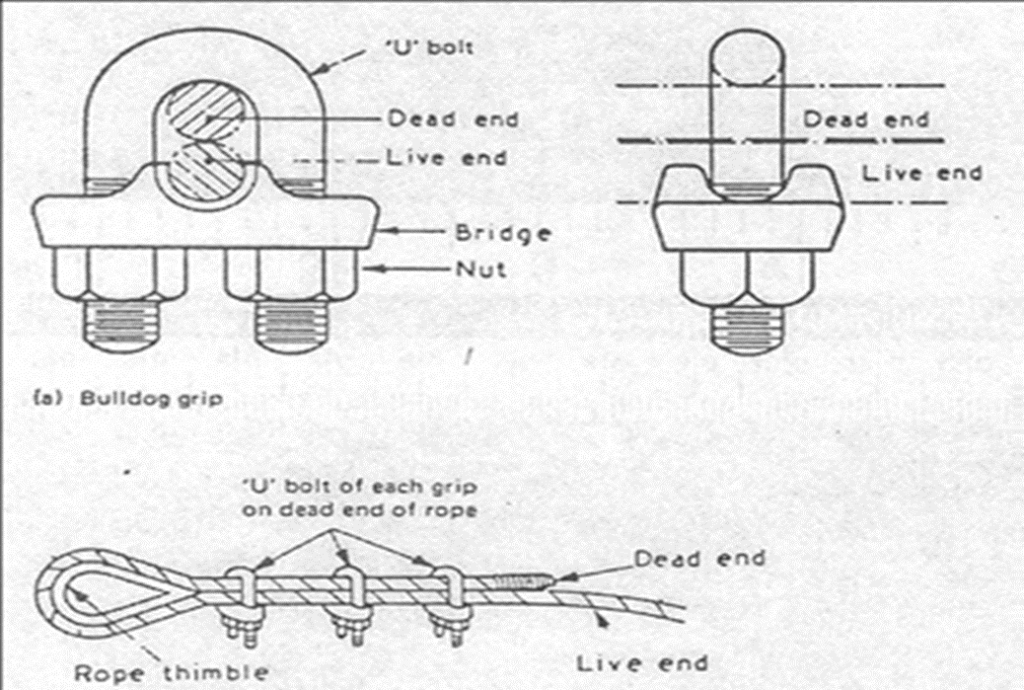

Turnbuckles correct way of lashing

Wire Lashing

Chain Lashing

Chain Lashing

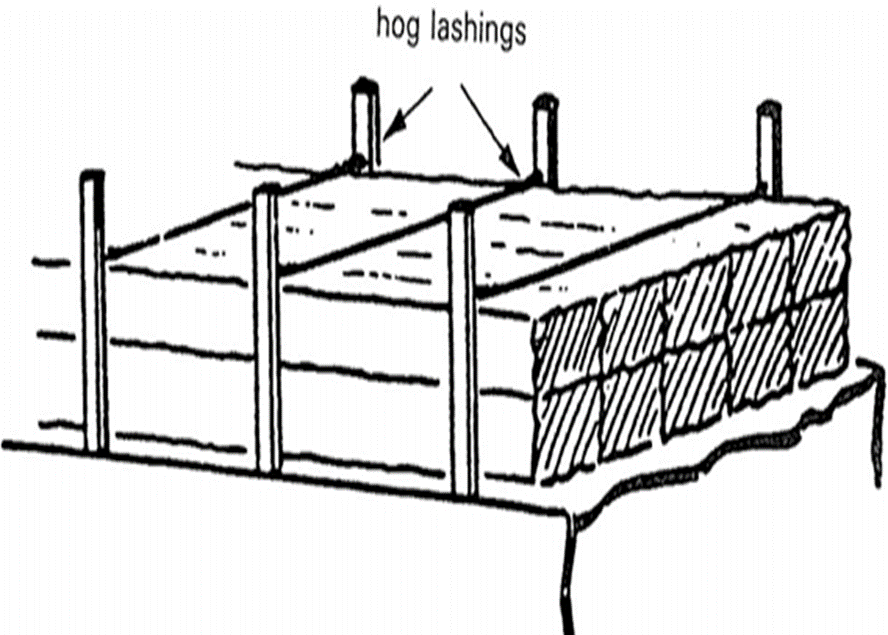

Hog Lashing

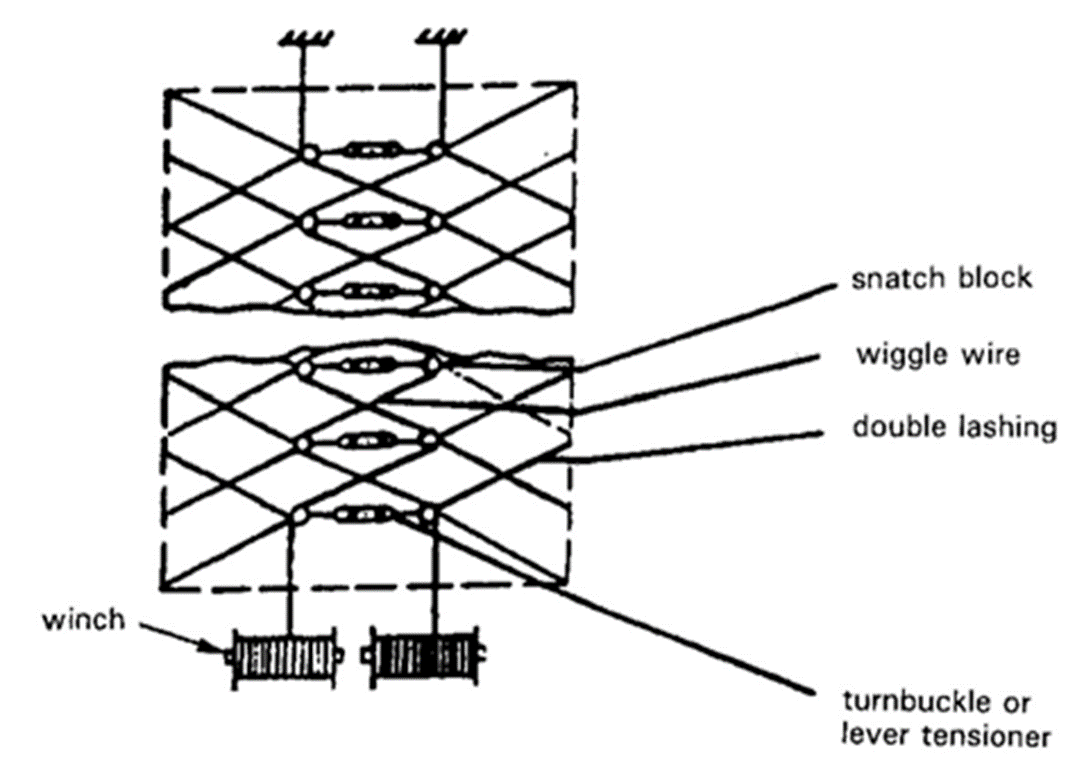

Wiggle Lashing

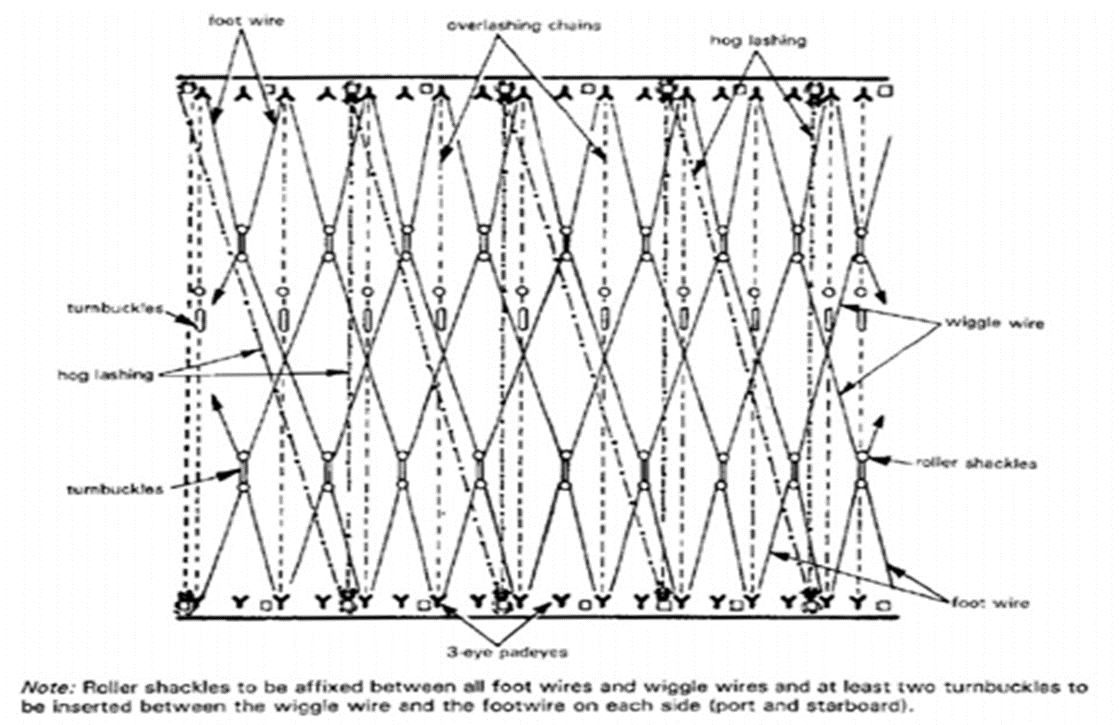

Arrangement for wiggle lashing

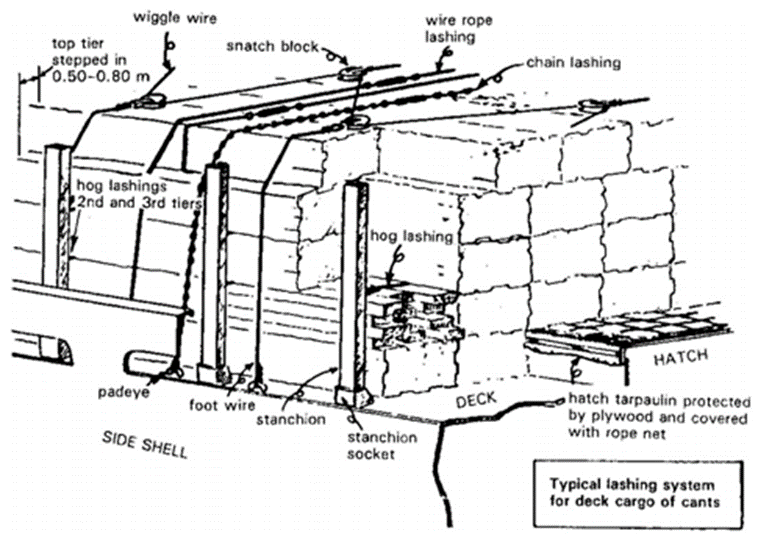

Hog, top over and wiggle lashing

Uprights

Uprights, designed in accordance with chapter 7 of the code, should be used when required by the nature, height or character of the timber deck cargo as outlined in this code.

When uprights are used, they should:

1. Be made of material of adequate strength, taking into account relevant parameters such as; the breadth of the deck cargo, the weight and height of the cargo, the type of timber cargo, friction factors, additional lashings, etc.;

2. Be spaced at intervals between the centerlines of two uprights not exceeding 3 m so that preferably all sections of the stow are supported by at least two uprights; and

3. Be fixed to the deck and/or hatch cover by angles, sockets or equally efficient means and be secured in position as required by the CSM.

Securing of loose or packaged sawn timber

Loose or packaged sawn wood

Uprights should be used for loose sawn wood. Uprights or stoppers (low uprights) should also be used to prevent packaged sawn wood loaded on top of the hatch covers. The timber deck cargo should in addition be secured throughoutt its length by independent lashings.

The maximum spacing of the lashings referred to above should be determined by the maximum height of the timber deck cargo in the vicinity of the lashings:

1. For a height of 2.5 m and below, the maximum spacing should be 3 m;

2. For heights of above 2.5 m, the maximum spacing should be 1.5 m; and

3. On the foremost and aft most sections of the deck cargo the distance between the lashings according to above should be halved.

As far as practicable, long and sturdy packages should be stowed in the outer rows of the stow and the packages stowed at the upper outboard edge should be secured by at least two lashings each.

When the outboard packages of the timber deck cargo are in lengths of less than 3.6 m, the spacing of the lashings should be reduced as necessary or other suitable provisions made to suit the length of timber.

Rounded angle pieces of suitable material and design should be used along the upper outboard edge of the stow to bear the stress and permit free reeving of the lashings.

Timber packages may alternatively be secured by a chain or wire loop lashing system, based on the design principles contained in chapter 6 of the code.

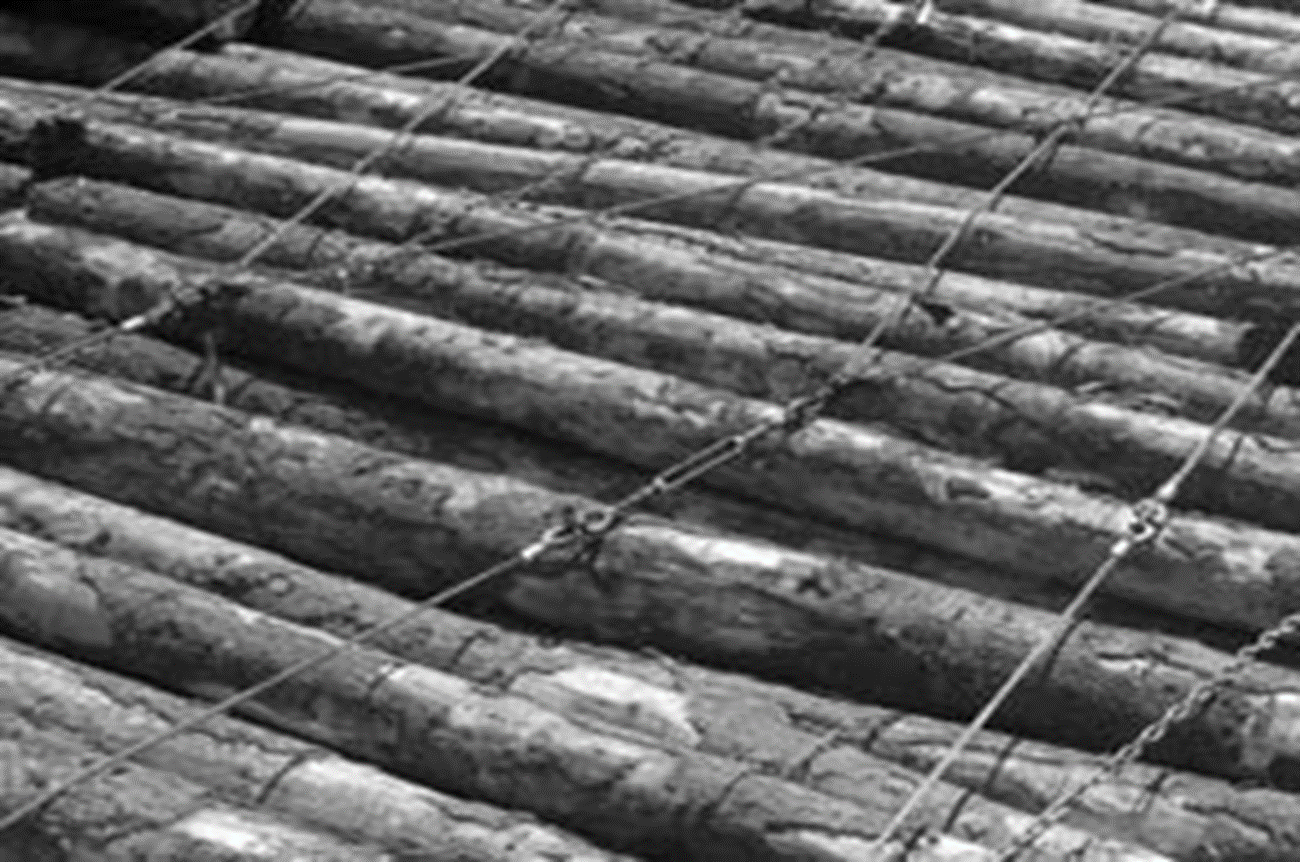

Securing of logs, poles, cants or similar cargo

Logs, poles, cants or similar cargo

The round wood deck cargo should be supported by uprights and secured throughout its length by independent lashings spaced not more than 1.5 m apart.

If the round wood deck cargo is stowed over the hatches and higher, it should, in addition to being secured by the lashings recommended above, be further secured by a system of athwartship lashings (hog lashings as described in the code) joining each port and starboard pair of uprights.

If winches or other adequate tensioning systems are available on board, every other of the lashings mentioned above may be connected to a wiggle wire system as described in the code.

The recommendation of loose or packaged sawn timber should apply to a timber deck cargo of cants.

Testing, examination and certification of lashing gear.

1.All lashing wires, chains and components used for securing the timber deck cargo should be tested, marked and certified according to national and international regulations by a recognized institute. Copies of the certificates must be kept on board.

2.A visual examination of lashings and components should be carried out every 12 months. Before loading a visual examination of all securing points on the ship and uprights should be performed and defects rectified.

3.No treatment which could hide defects and reduce strength of mechanical properties should be carried out.

4.One or more lashing plans should be provided and maintained on a ship carrying timber deck cargo.

Guidelines for the Underdeck stowage of logs.

1.Before loading, a pre-stow plan must be developed for maximum utilisation of the available space taking in to account dimensions, capacity, and configuration of the holds, length of the cargo and capacity of cargo gear.

2.Structural members in the holds, frames and equipment should be examined to determine if they affect the carriage of cargo and they should be protected during loading, stowage and unloading operations.

3.Side spar ceilings and pipe guards should be in place.

4.Bilge strainers should be clean and effective against admission of debris.

5.It may be necessary to retain Ballast in wing tanks to facilitate loading.

6. Logs should be hoisted from as close as possible to the shipside so that the swinging is minimum. They should be gently lowered into the space and stowed compactly. They should be lowered in the hold and slid gently to sides of the hold and sliding on to the sides may be difficult once the holds are nearly full.

7. Logs are generally loaded in F and A direction. Loose tackles may be used to pull the logs to sides.

8. Voids should be filled in with dunnage and chocked.

9. After loading a check of all bilge and tank sounding is to be done to ascertain ship’s watertight integrity.

The Rolling period Test

The roll can be started by swinging a weight, raising or lowering it as far off the centre line as possible or by men running across the deck in unison. Once the rolling has been induced, the inducing force must be stopped and the weight placed on the centre line.

The time is taken for five or more continuous rolls, by means of a stopwatch, starting from when the ship is at on extreme end, just before she rolls over to the other side till the time she comes back after rolling over to the other side and is about to begin, the next complete to and fro roll. This is repeated twice, making the ship come to rest between the two sets of observations. Readings which vary considerably from the average must be discarded and the average value of “T” found out. The GM can now be found out from the table or calculated.

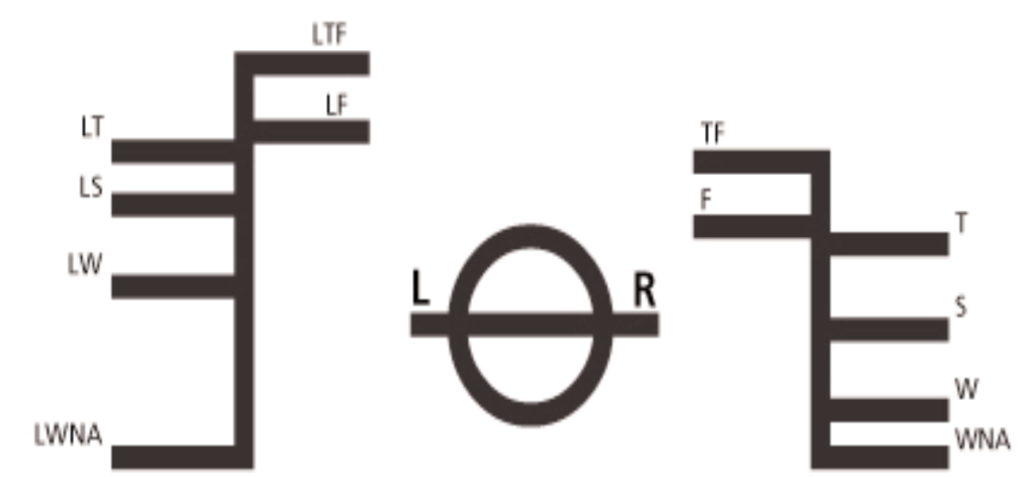

Timber load lines

Many vessels are marked with special timber load lines in addition to the normal load lines. The timber load lines are

calculated on the premise that a full timber deck cargo will be carried, and an entirely separate set of cross-curves of stability is produced for the full timber deck cargo condition. The timber load lines allow the vessel to load to a deeper draught (and hence a larger displacement) than would otherwise be the case.

Disputes have arisen between shipmasters and charterers, as to the strict application of the timber load lines. The following guidelines should be applied:

- These regulations require that the timber be stowed as solidly as possible to at least the standard height of the superstructure. For instance, in ships of 125m or more in length, this equates to a uniform height of not less than 2.3m. In ships under 125m in length, the stow should reach a uniform height of not less than the height of the break of the forecastle head.

- If the timber is stowed to a lesser height than indicated above or is not correctly stowed in any other way, i.e., not the full length of the well or not from side to side, then the ship is not permitted to load to the timber line.

- When a ship is assigned a timber load line, in order to load to those marks the vessel must be loaded with a timber deck cargo which is correctly stowed in accordance with the deck cargo regulations and the IMO Code of Safe Practice for Ships Carrying Timber Deck Cargoes, 1991.

- When timber is correctly stowed on deck as referred to above, the ship may load to the timber load line irrespective of the quantity or type of cargo stowed below decks. The reduction in freeboard enjoyed by a ship which is assigned timber load lines, is permitted because of the buoyancy contribution of the timber deck cargo to the ship’s stability characteristics.

Timber Load Line