Aim

Carrying cargo with care is our first aim and ventilation is one of the aspects that we need to ensure at all time. Let us see what ventilation means.

Introduction

As you know, most of the cargoes are loaded in cargo compartments. These are closed before proceeding to sea, to prevent any external elements, like foul weather, water, heat, cold, etc affecting the cargo. However, enclosing the compartment completely may lead to other problems. The damage to cargo due to non-ventilation needs more attention. Carrier would be held liable if this damage takes place. It is your duty to carry the cargo safely from one place to another, which means you should know how best to ventilate the compartment to prevent moisture damage to the cargo.

Need for Ventilation

It is necessary to ventilate a cargo compartment for the following reasons-

1. reduce the temperature of the air in the compartment and bring it on par with the ambient temperature.

2. To prevent damage to the cargoes which are—

- Susceptible to heat.

- Likely to decay or ferment.

- Subject to spontaneous combustion.

- Likely to be contaminated by the odours of other cargoes.

3. To expel the toxic, flammable or unwanted gases given out by the cargo.

4. To prevent formation of sweat and thus prevent damage to the cargo and rusting of the steel structure of the ship.

5. To prevent depletion of Oxygen Content of the air inside the compartment. This occurs due to the Oxidation of steel structure or steel cargo and formation of rust.

6. To make the compartment sufficiently safe for any person to enter it for any Purpose, and to make it reasonably habitable for labourers to work there.

Why Ventilate

Imagine that assorted cargoes have been loaded in a cargo compartment of your ship and the same has been completely closed and made weather tight, for a long passage of say, couple of weeks. Even if the compartment is not air tight, the ventilation is restricted. In such a case, following changes are likely to occur inside the compartment.

Rise of Temperature

The deck above the compartment will get heated by sunlight, which in turn will heat the air inside by conduction. Due to the lack of ventilation, there is no chance for the heat to be dissipated. Hence the temperature inside the compartment will rise.

“This effect is very similar to what will happen if you close all doors and windows of a room of your house for a day or two and then enter it. You will definitely feel it to be warmer and stuffy than the rest of the house.”

If the ship is proceeding towards the warmer regions, then the rise in temperature will be fast and substantial, but if the ship is proceeding towards the colder regions, then the temperature inside may not increase at all.

In case of certain cargoes, which may undergo exothermic reactions i.e. they evilive heat due to chemical reactions, the rise of temperature will be large. Examples of such cargoes are — Coal, nuts, beans, hay, wet hides, oil cakes, pepper, etc.

Effects of the rise of temperature on the cargo

The rise in temperature will not directly affect most of the cargoes but certain cargoes undergo changes. Grain or seeds of any kind will tend to germinate and shall start sprouting. This is a natural process, which occurs over a period in the presence of moisture, but it is aggravated and expedited due to rise in temperature. Fruits will start ripening and deteriorating at a faster rate than normal. Caution

Certain organic products like green sugar molasses, etc. start to evolution of alcoholic vapours and carbon dioxide gas. Unless these gases are fermenting leading exhausted out of the compartment, they will be a hazard to persons entering it.

The pressure inside gas cylinders carried as cargo will increase. This could cause leakage of gas and other related problems.

Certain cargoes like coal, animal meal, oil cakes, etc. evolve flammable gas due to exothermic reaction. The consequential rise in temperature and the presence of flammable gas and atmospheric oxygen in the right proportion could lead to spontaneous combustion, unless the rise in temperature is controlled and the flammable gas is expelled out of the compartment.

Caution

■Spontaneous combustion is said to occur when any material, which undergoes exothermic chemical reaction, catches fire due to rise in temperature and evolution of flammable gas without any external source of fire.

■ Certain chemicals and drugs may undergo chemical changes making them valueless.

■ Even though proper ventilation of a cargo compartment will make it reasonably safe to enter, it is extremely important that before you enter it, especially at sea when the hatch cover is closed, you must take certain precautions for your own safety. These will be explained in the subsequent lessons. In any case, you will never enter the compartment without the specific permission of the master.

Accumulation of gas in the compartment

Certain cargoes have a natural tendency to evolve gases, which could be toxic or flammable in nature, e.g. —

■ Rice gives out carbon dioxide.

■ Food products, when they start fermenting due to any reason,give out ethyl alcohol and carbon dioxide gases.

■ Coal gives out flammable methane gas (Marsh gas).

■ Petroleum products and crude oil, give out hydrocarbon gases, which are both toxic and flammable.

Accumulation of these gases in the compartment could seriously harm any person entering it for any work. Such accumulation could lead to fire and explosion. When an appropriate mixture of flammable gas and air is exposed to a spark, fire or explosion may result.

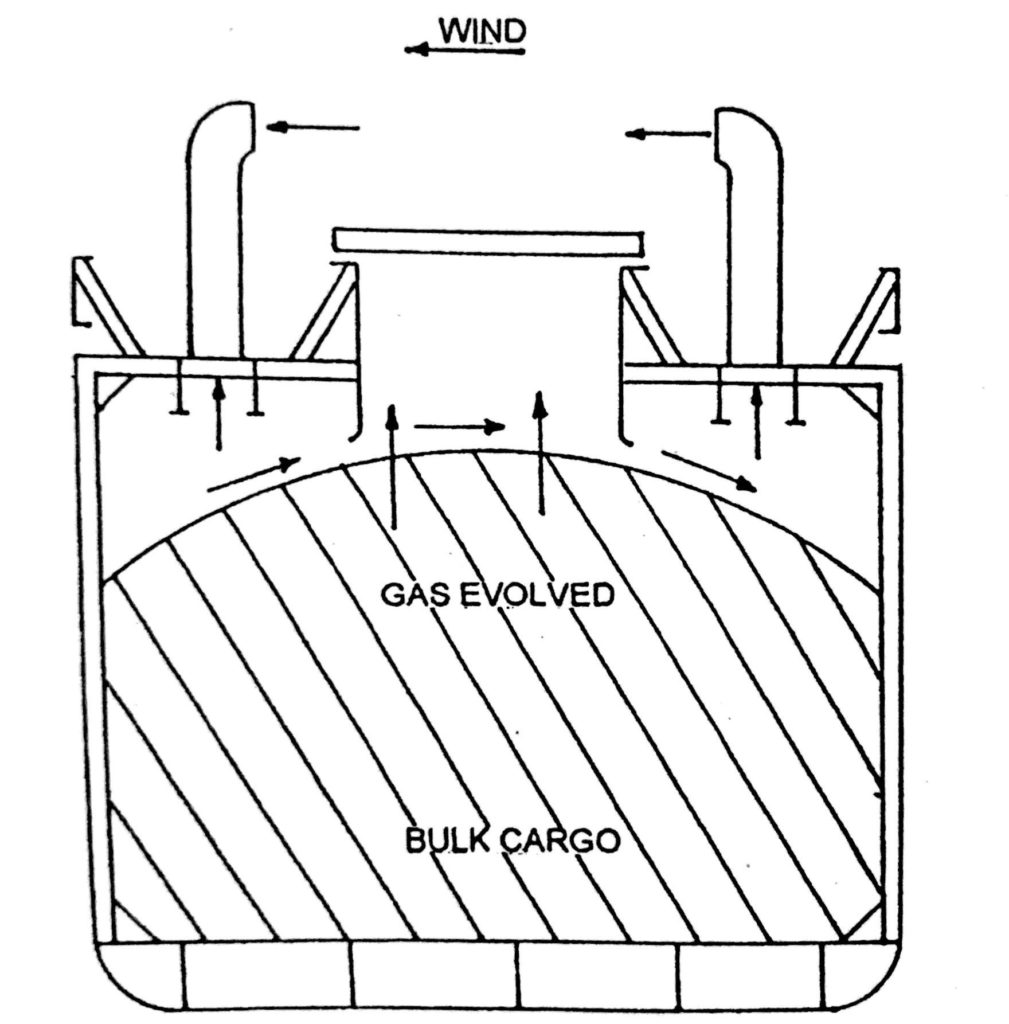

Surface Ventilation

Certain cargoes when loaded in bulk give out flammable gas and generate heat due to exothermic reaction. Coal is a very good example of this process. If the heat generated over a period is sufficiently high, then the presence of the flammable gas and the atmospheric oxygen in the right proportion could lead to spontaneous combustion. Hence, it is important that not only the gas is expelled but also it should be done without injecting too much oxygen within the cargo.

To achieve this purpose, ventilation of only the surface of the cargo is carried out without allowing too much air to permeate within the lower levels of the cargo. Opening a set of ventilators can achieve this. Such vents do not have trunking leading to the lower part of the compartment, or their trunking is blanked. The air entering through these ventilators will dilute the atmosphere above the cargo and expel the flammable gas, as it rises upwards through the cargo, via another set of ventilators. This will also help in controlling any substantial rise of temperature in the compartment.

To provide extra surface ventilation, the hatch covers may be partially opened, provided the weather conditions permit the same.

Sweating

If a cargo has been loaded in a warm region and the ship proceeds to a cold region, then the lack of ventilation could lead to condensation of water on the ship’s side. This phenomenon will be explained in detail in the later part of this module. The condensed water could damage the cargoes, particularly those of hygroscopic nature, i.e. those which have a natural tendency to absorb moisture e.g. coffee powder, grain, rice, herbs, confectionery, timber, etc. It could also accelerate the rusting of steel inside the compartment

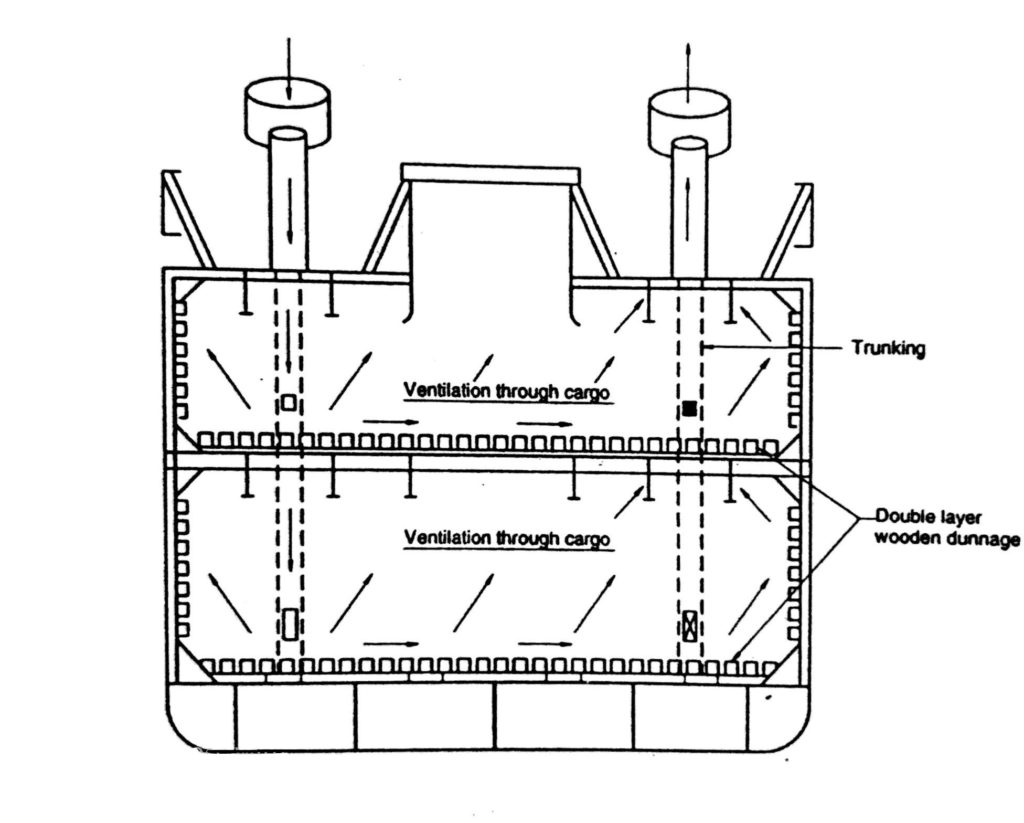

Thorough Ventilation

`This is required for most cargoes to achieve all the purposes stated earlier in the paragraph on recapitulation. The ventilators fitted on the deck have trunking leading along the ship’ side or bulkheads to the -lower part of the compartment. The air’ entering through one set of ventilators reaches the bottom of the compartment via trunkings, rises upwards through the cargo and finally exhausts out of another set of ventilators. Normally all the ventilators of the compartments have trunkings leading to the bottom. When the ventilation is started, the trunkings of those ventilators, which are to be used for exhaust, are blanked so that per-force the air entering the compartment through the inlet ventilators has to rise upwards through the cargo rather than through the trunkings, to reach the exhaust ventilators. By doing so all the harmful gases present in the pockets within the cargo will be driven out of the compartment.

Contamination of cargoes due to odours

Certain cargoes have natural odours e.g. tea, coffee, tobacco, incense, fertilisers, hides and skins, condiments and spices, aromatic oils and seeds, dyes, herbs, animal meals, detergents, etc. Odours could penetrate other cargoes like food products, etc. and make them unfit for use or for human consumption, not because the product has lost its inherent properties but because of the foreign smell in it.

Exhaust gas from vehicles

When vehicles are driven inside the ro-ro ship, as explained in the earlier lessons, lot of exhaust gases are given out, which, if not expelled, will accumulate inside the compartment. These could be very harmful to the people working in that compartment.

Depletion of Oxygen

The cargo compartment is made of steel, which has a high affinity for oxygen. This leads to oxidation of steel and formation of rust. This is a natural process and can only be prevented or reduced by properly painting the steel to prevent it from coming into contact with the oxygen in the atmosphere. Even with the best efforts of the ship’s staff, corrosion takes place. Oxidation, which causes corrosion, will lead to the reduction in percentage of oxygen in the compartment. This reduction will be more pronounced if the compartment is loaded with steel cargo. If fresh air is not supplied by effective ventilation, then any person entering the compartment will collapse due to lack of oxygen.

Formation of sweat

Sweat is condensation of water vapour on cold surface inside the cargo compartment of a ship. If it occurs on the ship’s side, then it is called “ship sweat” and if it occurs on the cargo, then it is called “cargo sweat”. Due to natural process of evaporation, water turns into water vapour and remains suspended in the air. The maximum amount of water vapour, which the air can hold, depends on the temperature of the air. Higher the temperature greater is the capacity to hold water vapour. When the air at a given temperature contains a maximum amount of water vapour, which it can hold, then it is said to be saturated and it’s, humidity is said to be 100%. if now the temperature of the air falls it cannot hold the same amount of water vapour and so the excess amount will condense in the form of water drops on any cold surface, with which the air is in contact. This is called sweat.

Suppose a given parcel of air, (e.g. the air inside a cargo compartment), is at a certain temperature and it is unsaturated (i.e. its humidity is less than 100%). If now the temperature of this air is reduced so that it becomes saturated, condensation shall take place. The temperature at which it occurs is said to be the dew point of that parcel of air. This can be determined by using the Hygrometer or Psychrometer. Appropriate data tables given in the meteorological codes will indicate the dew point. We shall look at the use of codes in a later lesson. It is therefore obvious that in order to prevent condensation the air temperature inside the compartment should not be allowed to fall below its dew point.

Ship Sweat

Suppose the ship has loaded cargo at a port in a warm region. This means that the air inside the compartment is warm and it will be holding substantial amount of water vapour. The compartment is now closed and the ship proceeds to the colder regions. The cold water outside will cool the ship’s steel hull, which in turn will cool the air inside the compartment by conduction. If the temperature of the air close to the ship’s side falls below its dew point, condensation will occur on the colder ship’s side with which the air is in contact.

Note It!!!

You must have noticed this happening in your everyday life. When you pour cold water in a glass, very soon water particles appear on the surface of the glass, on the outside of the glass. This is because the cold water has cooled the body of the glass, which in turn cools the air in contact with it. This reduces the temperature of the surrounding air, in the immediate vicinity of the glass, below its dew point and condensation occurs on the cold glass surface. Normally the condensed water will trickle down the ship’s side into the bilges and would be pumped out subsequently. However, if the water is exposed to the cargo, particularly those of hygroscopic nature, then it will damage the cargo. In addition, the water drops on the steel shipside could accelerate the formation of rust, which creates its own problems.

To prevent formation of ship sweat, the cargo compartment should be ventilated extensively so that the outside cold air, having low dew point, will replace the inside warm air having comparatively higher dew point. As the days pass by, the temperature of the inside and the outside air will equalise and there will be no possibility of formation of sweat.

To decide whether ventilation is necessary or not, you should make use of the hygrometer to measure the dew point of the air inside and outside the compartment, and apply the following thumb rule: “If the dew point of the outside air is less than the dew point of the inside air, ventilate the compartment.”

Cargo Sweat

This occurs when the ship has loaded cargo in the cold region and is proceeding towards the warmer regions. If you allow ventilation during the voyage, then the warm and moist air from outside will enter the compartment and be exposed to the cold air and the cargo. This will reduce the temperature of the incoming air and, if it falls below its dew point, condensation will occur on the cold cargo.

#Obviously, the answer to this problem is to restrict ventilation. In other words, you should ascertain the dew points of the outside and the inside air and apply the thumb rule:

“If the dew point of the outside air is higher than the dew point of the inside air, restrict ventilation.”

Do You Know?

You must have noticed this happening during your stay on board ship. When you wake up in the morning and walk out on the open deck, very often, you will notice tiny drops of water spread all over the deck. This has happened because, during the night, the temperature of the steel deck cooled below the dew point of the air adjacent to it. Water contained in the air therefore condensed on the steel deck.

Similar phenomena can be seen when you go for an early morning walk in a park. You will notice drops of water, called dew, clinging to the grass and green plants near the surface. Formation of fog, mist and cloud are other examples of this process, which will be explained in detail in meteorology lessons. This condensation of water may damage the cargo, regardless of whether it is hygroscopic or not. There is no possibility of removing this water after it settles on the cargo, as it is not likely to reach the bilges.

Total restriction of ventilation may be neither feasible nor desirable. it is not feasible because it is practically impossible to make all the openings such as the hatch covers, booby hatches and ventilators totally airtight. It is not desirable also because it could lead to accumulation of harmful gases inside the compartment. Hence, controlled ventilation is resorted to for short periods, particularly during the day. in addition, de-humidifiers are used with the ventilation system to remove the moisture from the air before it enters the compartment, and make it as dry as possible. By doing so, formation of sweat is reduced, if not eliminated and gradually the temperature of the air inside and outside the compartment will equalise.

Fact

De-humidification is carried out by using chemicals like silica gel, activated alumina and lithium chloride. They have very high affinity for water and if moist air is passed over them, they will absorb the moisture in the air, thus making it dry. Later the chemicals are heated to release the collected moisture and then reused as de-humidifiers. The absorption of the moisture and the drying of the chemicals is continuously carried out when the ventilation and de-humidification is started.

Natural Surface Ventilation

Cowl Ventilator

Obviously, if there is likelihood of formation of cargo sweat, the ventilation will be restricted, depending on the nature of the cargo. If the cargo gives out harmful gases, which have to be expelled, then controlled ventilation is to be used with the help of de-humidifiers even if it leads to some cargo sweat. To achieve effective through ventilation following additional arrangements are made such as: –

- Spar ceilings are fitted on the ship’s side frames so that the cargo is stowed clear of the ship’s side.

- Double layer of wooden dunnage is laid at the bottom of the compartment .

- If the cargo consists of bags, then these are not stowed compactly. They are laid side by side without overlapping them. This allows free circulation of the air within the cargo.

- Certain special cargoes like rice require very sophisticated methods of dunnaging and separation to provide effective through ventilation. Such special requirements will be explained at a later stage.

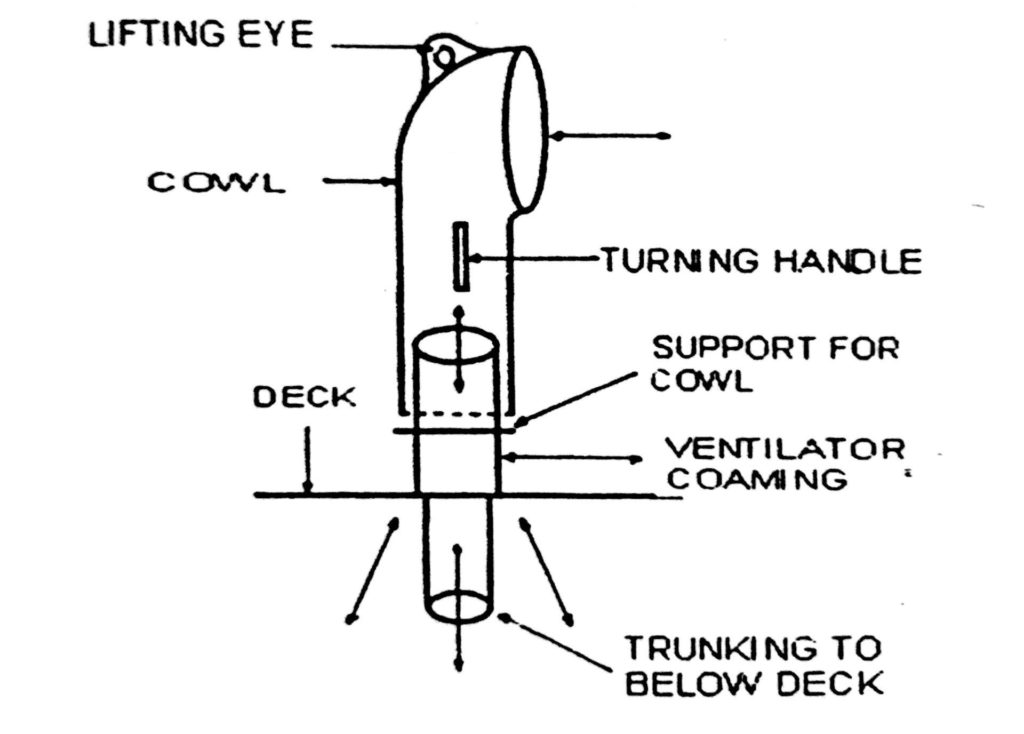

Natural Ventilation

This is carried out with the help of cowl ventilators shown in above figure. These are fitted on deck or on top of mast house. The mouth of the ventilator can be turned around in the appropriate direction depending on whether it has to be used as exhaust or inlet.

As per the normal practice, the leeward ventilators are turned towards the wind and the windward ventilators are turned away from the wind. The air enters the compartment through the leeward ventilators, flows in the opposite direction towards the windward ventilators and finally exhausts out of them.

During the voyage the duty officer should keep watch on the wind direction and turn the cowls accordingly. if the ventilation has to be restricted, then all the cowls are turned away from the wind. If the restriction of the ventilation is very critical, then the cowl is lifted out of its coaming and the opening is plugged by a wooden disc and adequately closed by a canvas cover. This not only prevents entry of the air, but also makes the opening weather tight in case of bad weather.

Very often natural ventilation cannot be effectively carried out because it suffers from the following disadvantages.

It is dependent on the direction of the wind, which should normally be from forward of the beam. ventilation is not possible if there is no wind or if it is blowing from abaft the beam.

It is reasonably effective for surface ventilation but not good enough for through ventilation, unless the wind force is sufficiently high, and from appropriate direction, to penetrate deep into the compartment.

The air entering the compartment is expected to force the harmful gases out of the exhaust ventilators. However, this-is not always effective and very often it merely helps in diluting the gases inside the compartment, unless the wind force is sufficiently high.

Thorough Ventilation by mechanical ventilator

If ventilation of cargo is very important, the cowls have to be constantly trimmed in the correct direction, whether by day or by night, with every shift of the wind direction. Any default on the part of the duty officer in this regard could damage the cargo.

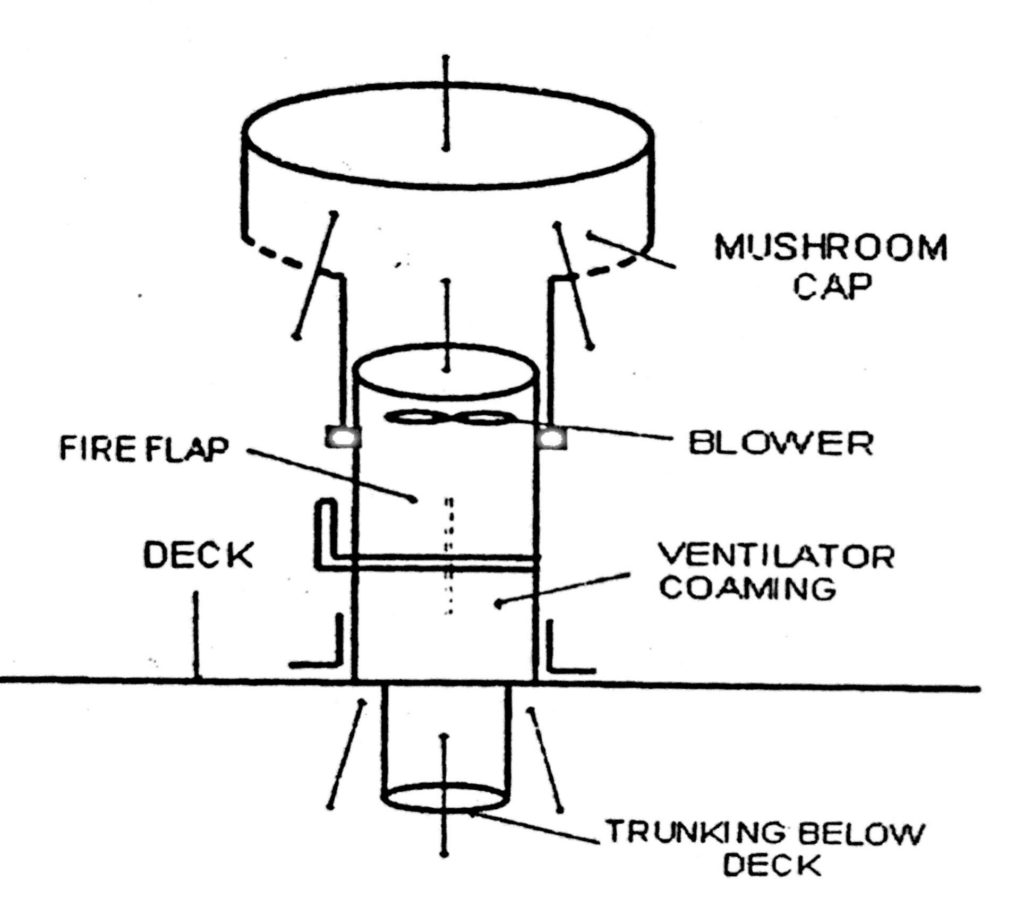

Mechanical forced ventilation

This method overcomes the disadvantages of the natural ventilation system. The design of the ventilator is shown in below figure. The whole arrangement is permanently fitted on deck or on mast house. Electrical blowers are fitted inside the ventilator to either inject the air into or exhaust the air from the compartment.

If only surface ventilation is required or if harmful gases have to be expelled, then the blowers of the ventilators on one side of the compartment are operated in the exhaust mode. As the air with the gases is expelled from the compartment, automatically fresh air enters through the ventilators on the opposite side, without the help of the blowers. This process enables the gases to be physically dragged out of the compartment and be replaced by fresh air.

When through ventilation is required and expelling of gases is not of paramount importance, then blowers of one set of ventilators are operated in the inlet mode to force the fresh air into the compartment. With the build-up of pressure inside the compartment, the air is automatically exhausted out of the other set of ventilators without operating the blowers.

As blowers of only one set of ventilators will be operated at a time, these should be periodically inter-changed during the voyage to avoid over-stressing the same blowers.

Because of the shape of the ventilators, it cannot be used for natural ventilation. In other Words unless the blowers of at least one set of ventilators are operated, ventilation is not Possible. Hence, the easiest way to restrict ventilation is to stop the blowers. However, if restriction of ventilation is very critical, then, besides stopping the blowers, the flaps fitted inside the ventilators are turned by a handle outside the ventilator, to close the trunking. These flaps are also effective in preventing entry of water during bad weather and in controlling a fire, which may occur inside the compartment. They are commonly referred to as “fire flaps.”

The biggest disadvantage of this system is the electric blower itself. If flammable gas is being expelled from the compartment, then, due to sparking of the motor or at any electrical junction, the gas could ignite. To prevent it, the electric motor and the entire electrical arrangement have to be made intrinsically safe and flame proof.

Very often these ventilators are also fitted with a wire mesh to act as a spark arrestor so that any sparks from the ship’s funnel or from the electric blower will not be able to enter the trunking.