Safe Practices:

The Aim of this section is to ensure that the seafarer does not, at anytime, jeopardize the safety of his shipmates or himself when working in hazardous areas.

a) Safe practices for working over side and aloft.

b) Safe practices when entering into enclosed spaces

Safety is the operative word. You will never be able to forgive yourself if a fatal accident occurs on your ship, particularly if you have been negligent in any way whatsoever. The memory will haunt you for the rest of your life, that is, if you have not suffered yourself.

Practice of safety is not only for the ship but it is most important for you. Only when you practice safety with a commitment that you will avoid injuries and other losses.

Working aloft and over the side

A man working at a height may not be able to give his full attention to the job and at the same time guard himself against falling. Proper precautions should therefore always be taken beforehand to ensure personal safety when work has to be done aloft or when working over the side. It is necessary to take into account the hazards involved in work of this type. In particular:

- A stage or a ladder should be utilized when work is to be done beyond normal reach.

- Seafarers under 18 years of age or with less than 12 months experience at sea, should not work aloft unless accompanied by an experienced seafarer or otherwise adequately supervised.

- A safety harness with lifeline or other arresting device should be continuously worn when working aloft, outboard or overside.

- A safety net should be rigged where necessary and appropriate.

- Where work is done overside, life jacket should be worn.

- Lifebuoy with sufficient line attached should be kept ready for immediate use.

Follow the precautions stated below:

Do not allow overside work while the vessel is underway.

When working near the ship’s whistle, radio aerial or the radar antenna, the officer responsible for the job should ensure that power is shut off and notices posted on the bridge and in the machinery spaces before the commencement of work.

Before work is commenced on the funnel, the officer responsible should inform the duty engineer to ensure that steps are taken to control the emission of steam and harmful gases.

When work is to be done overside on a stage or on the bosun’s chair, ensure that cargo slings or wires are not likely to affect the safety of those working overside adversely. Where necessary, the cargo work may be suspended for the period.

Care must also be taken while work is being done aloft or at a height, to avoid risks to anyone working or moving below. Suitable notices should be displayed. Tools and stores should be sent and lowered by line in suitable Containers, which should be secured in place for stowage of tools or materials not presently being used. When working aloft it is best to wear a belt designed to hold essential tools securely.

Tools should be handled with extra care when hands are cold or greasy or where the tools themselves are greasy. Tools should not be carried in pockets from which they may easily fall

Cradles and Stages

Planks and materials used for the construction of ordinary plank stages must be carefully examined to ensure that they are free from defect and have adequate strength.

Wooden components of staging should be stowed in a dry, ventilated space and not subjected to heat.

Ancillary equipment, blocks, purchases and gantlines should be examined before use. A defective item should not be used.

When a stage is rigged overside, two gantlines used in its rigging should at least be long enough to trail into the water to provide additional lifelines, should a person fall.

A lifebuoy and lifeline should also be kept ready close by.

An attending person shall always be on deck to keep a safety watch and to look after the needs of the persons working overside.

All ropes when in use should be kept clear of sharp edges.

The anchoring points for lines, blocks and lizard must be of adequate strength and, where practicable, should be permanent fixtures of the ship’s structure. Integral lugs can be tested with a hammer.

Portable rails or stanchions should not be used as anchoring points. Beam clamps and similar devices should be used solely for their intended purpose and only under close supervision.

Stages and staging, which are not suspended, should always be secured against movement. Hanging stages should be restricted against movement to the extent practicable.

In machinery spaces, staging and its supports should be kept clear of contact with hot surfaces and moving parts of machinery.

In the engine room, a crane gantry should not be used directly as a platform for cleaning or painting, but can be used as the base for a stable platform if appropriate precautions are taken.

Where men working from a stage are required to raise or lower themselves. great care must be taken to keep movements of the stage small and closely controlled. In every such case, an attendant should be at hand to help out, where necessary

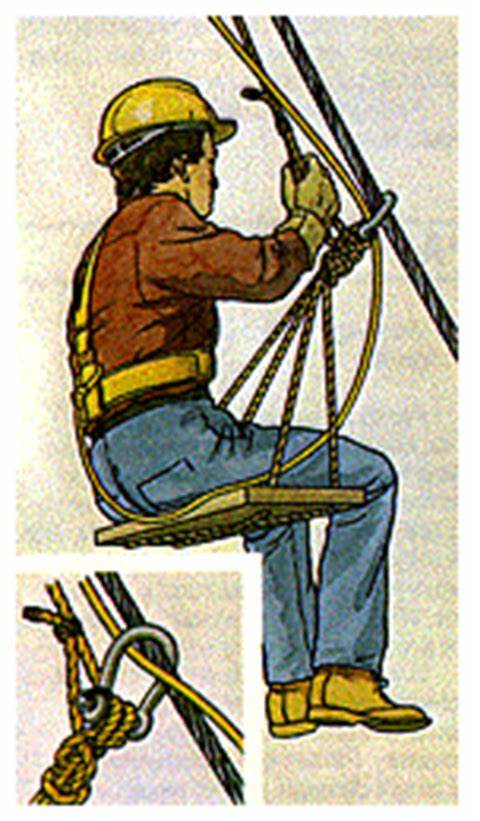

Bosun’s chair

When used with a gantline the chair should be secured to it with a double sheet bend and the end seized to the standing part with adequate tail.

Hooks should not be used to secure bosun’s chair unless they are of the snap shut type, which because of their special construction cannot be accidentally dislodged.

On each occasion that a bosun’s chair is rigged for use, the chair, gantlines and lizards should each be thoroughly examined, and the bosun chair rig tested before using.

When a chair is to be used for riding topping lifts or stays, it is essential that the bow of the shackle and not the pin, ride on the wire. The Pin, in any case, should be seized.

When it is necessary to haul a seafarer aloft in a bosun’s chair it should be done only by hand, a winch should never be used.

Ropes

Whether it is a lifeline to a harness or gantline to a bosun’s chair or stage, the safety of the man aloft or overside depends largely upon the strength of the line holding him and the way it is secured.

Many types of ropes both, man-made and natural fibres, have different resistance to weather, sunshine and contamination by substances used on the ship, which may seriously weaken the rope.

The person responsible for the work being undertaken should ensure that all ropes, lifelines, gantlines etc employed for a particular job are resistant to attack by substances that might be used during the course of that job. Natural fibers ropes or a mixture of natural and man-made fibres should be used with care. Similarly, care should be taken in the selection and use of ancillary equipment such as safety harnesses and safety nets.

Polypropylene ropes, which have the best all round resistance to attack by harmful substances, are generally preferred. However, these should not be exposed to strong sunlight, especially for long periods. They should also be of a type, providing a grip comparable to that of manila or sisal rope.

Ropes of man-made material stretch under load to an extent, which varies according to the material. Polyamide rope stretches the most.

opes should be inspected internally and externally before use signs deterioration and undue wear or damage. This particularly important if a gantline has not been used for some time. A high degree of Powdering between strands of man made fibre ropes indicates hard wear and impaired strength. The internal wear will be greater with ropes that stretch. Some ropes, for example of polyamide, become stiff and hard when overworked. You can check the powdering of the internal by twisting the strands against the lay.

All ropes and wires that are used on board are load tested. However, before taking them into use they should be examined thoroughly especially when being used as lifelines and gantlines, lizards and for stages or chairs.

Some superficial splashing or wetting of lines by corrosive or rotting substances may be unavoidable during the progress of the work. The ropes etc chosen should not be susceptible to damage by the contaminant and it should be sufficient to ensure that any effects of contamination are examined as soon as possible but in any case at the end of the day’s work.

Mildew does not attack man-made fibre ropes but moulds may form on them. This does not affect their strength.

Eye or short splices in ropes of polyamide or polyester materials should be made with four full tucks each with the complete strands of the rope followed by two tapers tucks for which the strands are halved and quartered for one tuck each respectively. Those portions of the splices containing the tucks with the reduced number of filaments should be securely wrapped with adhesive tape or other suitable material. Splices in polypropylene ropes should have at least three full tucks. The length of the splicing tails protruding from the finished splice should be equal to not less than three rope diameters.

Mechanical fastenings should not be used in lieu of splices on man-made fibre ropes because strands may be damaged during application of the mechanical fastening and the grip of the fastenings may be adversely affected by slight unavoidable reduction in the diameter of the strands.