The circumstances of a substantial claim recently settled by the Club in respect to cargo contamination and shortage clearly underline the fact that some masters do not understand that the suitability of cargo spaces for the intended cargo is their responsibility and theirs alone.

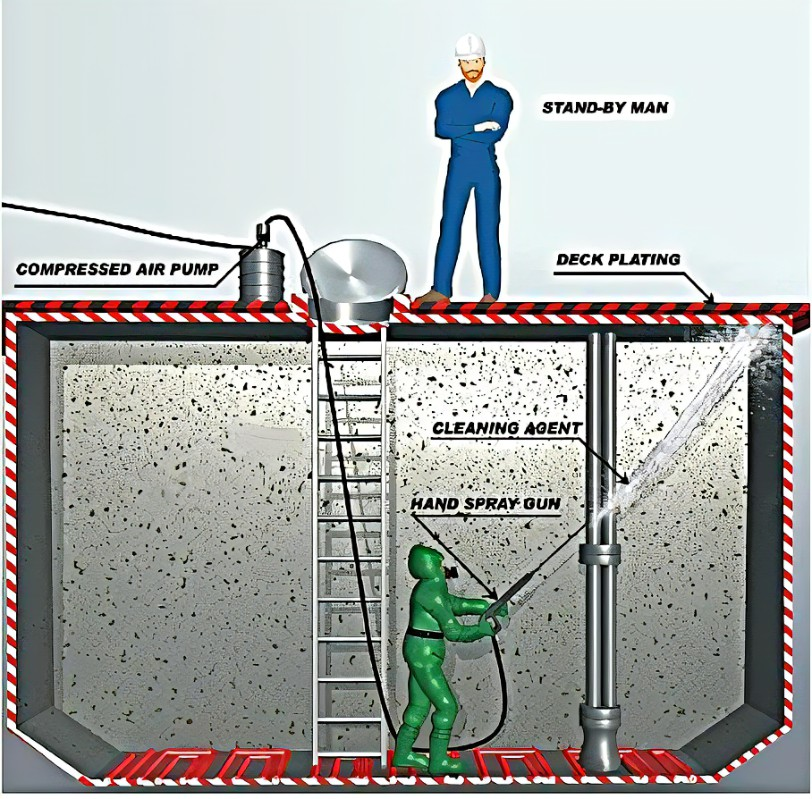

Inadequate Cleaning of Cargo Tanks

In this instance, the ship had been chartered to carry a cargo of crude oil. The previous cargo had been fuel oil and, on the ballast passage, all cargo tanks had been hot washed. At the load port, the slops were discharged to a barge. A charterer’s surveyor carried out a pre-loading inspection, during which it was noted that a significant volume of free water and oil/water mixture remained on board (ROB). The charterer’s surveyor issued a note of protest, but nevertheless gave instructions for loading to proceed. Loading was effected by ship-to-ship transfer and, prior to loading; the water content of the cargo had been determined as 0.25%. The ship loaded 69,616 m/t of cargo.

At the discharge port, the water content was determined as 1.4%, substantially in excess of the maximum 0.5% in the sales specification, and there was again a high ROB. The charterers made a substantial claim against the member in respect of costs and losses arising from the water contamination and for short out-turn. Lawyers advised that the member had a contractual obligation to exercise due diligence in preparation of the cargo tanks, and to provide a seaworthy ship. This duty was non-delegable and the charterer’s approval of the tanks prior to loading did not override that obligation. Against this background, the member’s defences to counter the charterer’s claims were viewed as weak and a settlement was negotiated.

The primary cause of this incident was the failure by the master to ensure that the cargo tanks were properly cleaned and drained prior to loading. The ROB prior to loading amounted to close to 1% of the ship’s deadweight, which is excessive and is indicative of poor drainage arising from a build-up of sludge on the tank bottoms due to a failure to ensure that tank cleaning was carried out effectively.

The attention of members is drawn to the conclusions reached by the member’s lawyers in respect of liability for this claim. Cargo claims arising from inadequate cleaning and preparation are frequently incurred by the Club and are invariably substantial in nature. Very often, the master has been lulled into a false sense of security by approval to load given by the charterer or his agent, only to find that this provides no defence against subsequent claims directed at the owner.

In light of the continued incidence of such claims, members are requested to ensure that their masters are clearly instructed as to their responsibility in the preparation of cargo spaces, and that this responsibility may not be delegated to a third party.

Contamination – Liquid Cargo

Contamination claims still occur with an alarming frequency. They are often expensive, usually avoidable and are invariably caused by leaking valves, dirty pipes or dirty tanks. Dirty pipes were the cause of a claim for the contamination of white spirit with heavy fuel oil. Careful cleaning had failed to remove cargo residue from the lines, which had solidified. Operators had not carried an intermediate cargo such as diesel, which would have cleared the lines without risk of contamination. Dirty pipes also caused the contamination of caustic soda with isopropyl alcohol. The bottom lines had not been properly flushed out and isopropyl alcohol, which remained, mixed with the caustic soda during loading. A leaking gate valve was the cause of the contamination of naphtha with palatinol. The ship had common piping and the single gate valve, which separated the two cargoes, had not been properly closed.

Operational procedures offer an easy solution to the prevention of claims from dirty pipes and tanks provided the procedures contain detailed instructions for tank and pipeline cleaning for various types of cargo. Standing instructions are also necessary on the correct loading sequence when more than one grade is carried and for loading intermediate cargoes after solidifying cargoes. Methodical sampling and testing during loading will identify a contamination early before the entire cargo is loaded and ‘first foot’ and ‘composite samples’ should always be taken.

Whilst operational procedures are both effective and inexpensive, they may not prevent contamination from a leaking valve. With the exception of modern chemical tankers, few tankers have a piping system, which is separate for each cargo tank. Most tankers have piping in a ring main where individual lines are cross connected by a branch line. The branch line is usually fitted with one or more isolation valves. Although two valves are considered to be the minimum required to segregate two different grades of cargo, owners often rely upon a single valve. This increases the risk of contamination if that valve leaks.

Contamination claims from leaking valves can only be avoided if the effectiveness of valves, which segregate the cargo, is maintained. Systematic pressure testing and repair of valves through a planned maintenance system is essential. Pressure testing is not the daunting task, which it may at first appear to be. Most owners arrange for testing during tank washing or during a ballast passage. Typically, a valve is checked with water being recycled at low pressure around the pumproom piping, but with a tank delivery valve open and the valves, which require to be tested, closed and then systematically opened. Seepage into a tank, on the other side of the valve being tested, is a clear indication of leakage. However, it is important, before testing to make sure that any tank, which is entered by a crewmember, is clean and gas free.

Different grades of cargo should always be segregated by at least two valves in a piping system, but the danger is that a valve may be leaking without the knowledge of the operator, effectively reducing the segregation to a single valve. We suspect that many operators, who do have double valve systems, only rely on the effectiveness of one valve – “the other valve is always open or closed and we never touch that valve.” The operator may believe he is safe, whilst in reality a contamination is only a matter of time. Operators are advised not to expect good performance as an indication that valves are effective but should test them regularly.

When claims do happen it is important for the Club to be able to defend them. This requires information. Good shipboard documentation, which clearly records details of previous cargoes, the cleaning procedures and systematic checks, is essential. Many claims have been lost because the Club did not have sufficient information to defend them.

The following checklist details some of the procedures and checks, which help to prevent contamination claims.

1. Written Procedures

- Document previous cargoes.

- Detail cleaning procedures carried out in all tanks and cargo piping systems.

2. before Loading

- Prepare a loading plan.

- Agree a pumping rate with the supplier.

- Take samples of cargo to be carried.

- Check all valves prior to commencement of loading.

- Check that the high and high high level alarm system is operational.

- Prepare all equipment necessary to curtail a possible spill.

- Commence loading one tank only.

- After sufficient cargo is loaded, stop the pump.

- Take a foot sample. If everything is in order, loading can be continued.

- Constantly check tank levels during the loading operation until completion.

3. before discharge

- Prepare a discharge sequence plan.

- Agree a pumping rate with the receiver.

- Be prepared to sound the receiver’s tanks prior to cargo operations commencing and agree the soundings.

- Take samples.

- Check all cargo valves.

- Prepare all equipment necessary to curtail a possible spill.

- Check the cargo pumps.

- Open all necessary valves to commence the discharge.

- Check the connection to the receiver.

- Have constant communication between barge and receiver.

- Start the pump and commence the discharge.

Remember

- Constant vigilance.

- Constant communication.

- Follow procedures.

- Be prepared for accidents.

Claims adversely affect your record and hence premiums will need to be increased.

Holds passed by surveyors

The charterer’s surveyor had passed the hold to load, yet the receivers rejected the cargo on arrival because of rust, and claimed damages. The master argued that it was not the ship’s responsibility because the charterer’s surveyor had agreed loading. Nevertheless, the receiver’s claim still succeeded. Cargo tanks had been cleaned properly and passed for loading by the charterer’s surveyor. The surveyor had also seen the first-foot samples, which showed no contamination. The receivers rejected the cargo alleging contamination because the flash point was wrong. The master argued careful loading and proper checks, blaming the charterer’s surveyor. The receivers claimed against the ship and won because the pipelines had not been cleaned properly and the first-foot samples had not been tested properly. In fact, a previous cargo had contaminated the cargo