What is HOT WORK??

Any work where temperature will be high enough to cause burning is hot work, typically: welding, cutting, burning, heating, use of some power tools generating heat, open flame, electric arc or continuous sparks. Hot work must not be carried without hot work permit issued by responsible Officer. Careless/unauthorised hot work can result in fire, explosion, heat injuries, strong light injuries (eyes effected) and shock injury to personnel.

Hot work area may be divided in 4 locations on board viz.

1. Engineers work shop

2. Engine Room

3. Poop Deck and Accommodation &

4. Cargo Area.

Of the above (1) is the least dangerous and (4) is the most dangerous.

However, Hot work permit is a must and related precautions listed therein are to be ensured. No Hot work shall be carried out without such permit, which shall be as per your Company’s own permit format.

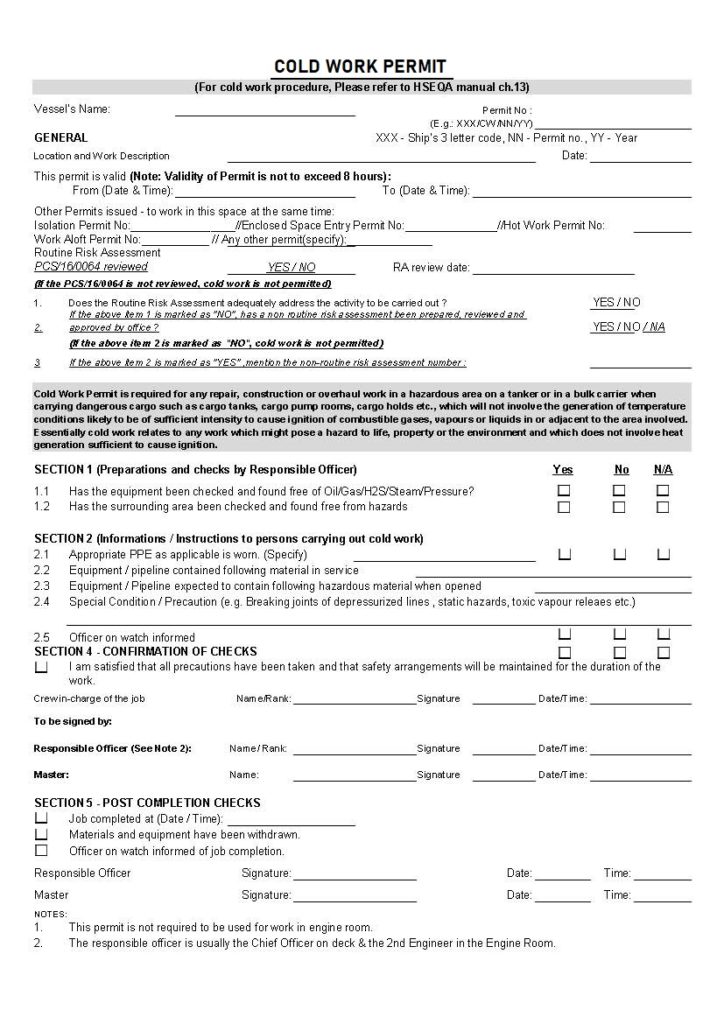

COLD WORK

This includes work other than hot work such as Blanking or Deblanking, Connecting and Disconnecting pipe work, Removing and fitting of valves, blanks or blinds, work on pumps, cleaning or mucking out oils and Semi Solid/Solid oily Residues.

Cold work permit must be obtained/issued before any such work. The responsible person shall ascertain whether it is ‘cold work’ or not. In absence of such permits injury to workers may result. Work without authorisation may also disable ship’s systems or services for emergency use or routine use or cause flooding.

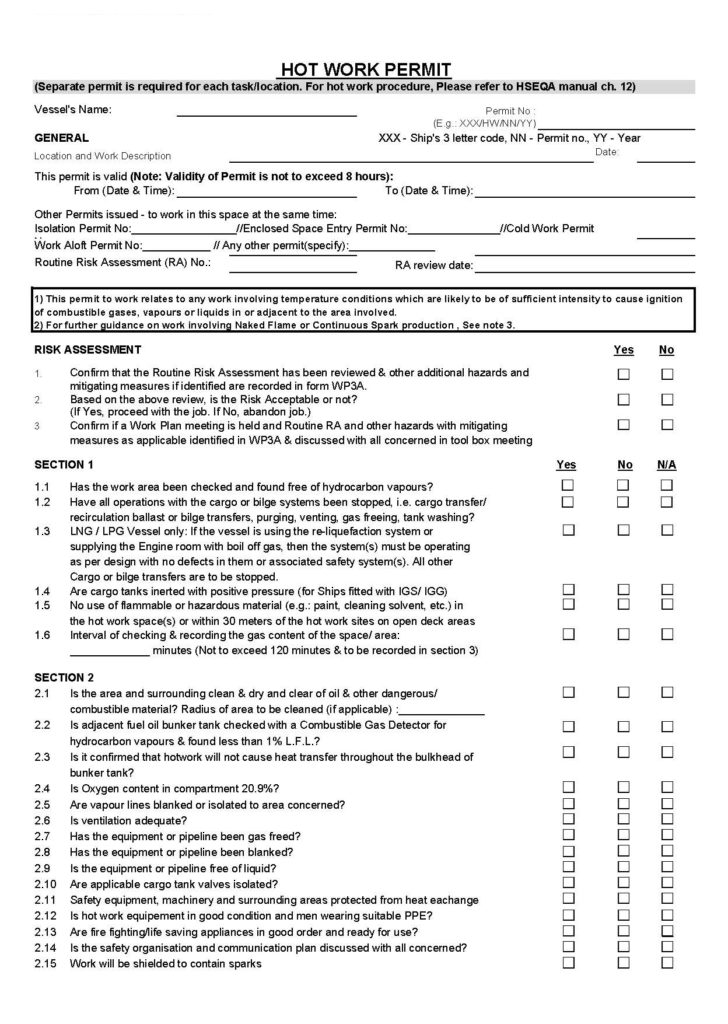

Hot Work Permit

This permit to work relates to any work involving temperature conditions, which are likely to be of sufficient intensity to cause ignition of combustible gases, vapour or liquids in, or adjacent to the area involved. Before completing this form, refer to the accompanying guidance notes, and to Section 2.8 of ISGOTT.

Guidance notes for hot work permit

a) Starting /finishing time must not exceed the Authorised Signatories’/Responsible Officer’s working hours.

b) Specific locations of hot work to be give

c) Description of hot work to include type of equipment to be used.

Section 1

Application to all hazardous work not involving naked flame or continuous spark production, and would include use of electrical equipment, use of air driven rotary equipment, sand or grit blasting, hammering and mechanical chipping and movement of equipment or materials over or near to machinery that is operating.

Section 2

Applies to all hot work involving high temperatures, open flames, electric arc or continuous source of sparks etc. This type of work includes but is not limited to welding, burning and grinding.

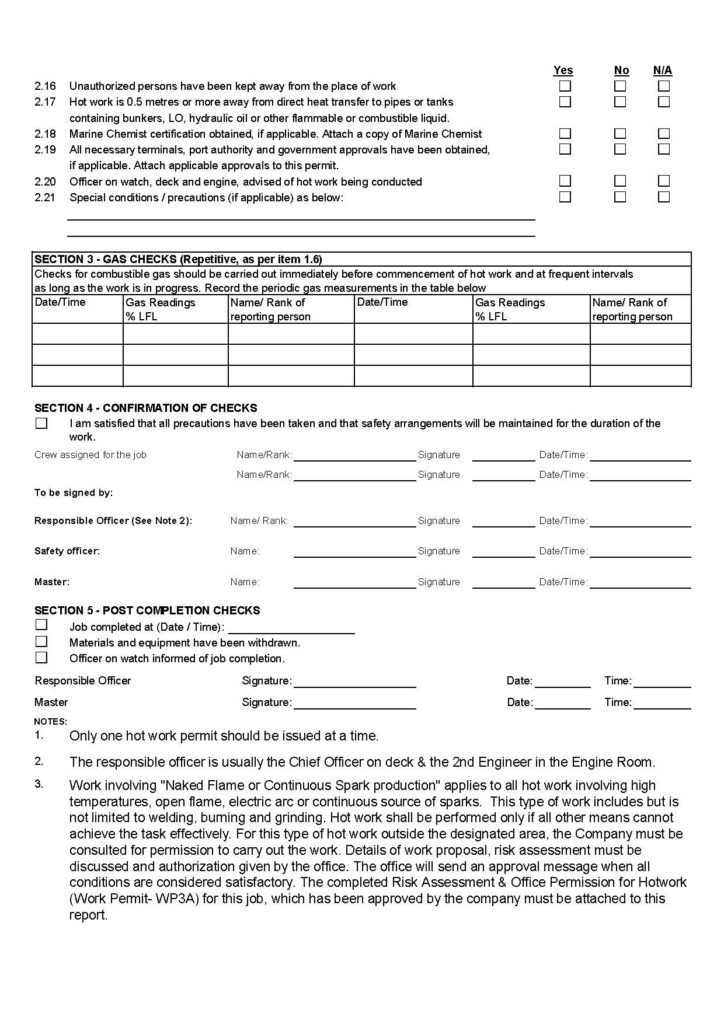

Tests for combustible gas should be carried out immediately before commencement of hot work and at frequent intervals as long as the work is in progress

Hot work precautions

Following are some of the precautions which should be taken before commencing hot work

► Immediately before undertaking hot work; the compartment should be ventilated until LFL reading is not more than 1% LFL. The ventilation should be continued during the period when the hot work is being carried out and the atmosphere should be checked regularly to ensure that the LFL reading does not increase above 1%.

► All sludge, scale and sediment should be removed from an area of atleast 10m radius around the area of hot work including reverse side of frames and bulkheads. Area immediately below the Hot Work site should also be cleaned.

► Periodic gas tests should be undertaken while work in progress.

► Suitably trained crew / fire patrol personnel should be present in the compartment and the fire water line should be under pressure when the work is in progress.

► All pipelines to tank being worked, should be isolated

► Adjacent tanks should be gas-freed inerted or filled with water to ensure that there is no flammable atmosphere in the immediate vicinity of the space where hot work is being carried out.

► Adjacent bunker tank may be considered safe as long as tests in ullage space reads not more than 1% LFL

► Other non-gas free tanks should be closed.

► Check to ensure no ingress of toxic or flammable gases / liquids from adjacent compartments.

► Combustible residue on the other side of bulkhead should be removed.

► Hot work on pipelines / valves may only be permitted where appropriate section of the pipeline is detached by cold work and open ended sections are sealed, section of pipe to be worked on should be gas free, heating coils should be flushed to remove any traces of hydrocarbon that may have leaked in.

► Concurrent cargo, ballast tank washing and any other operation using cargo system, should be stopped.

► Adequate fire extinguishing system should be available and ready for use.

► When alongside terminal, approval should be obtained from local authorities. Hot work permit may have to be obtained. Hot work permit should be also adopted at sea.

Validity of hot work permits not to exceed 12 hrs.

Most oil tanker owning companies require the tanker to obtain prior permission from the office for carrying out hot work in the hazardous area