Why Enclosed Spaces are Dangerous!!

Precautions to be taken in entering enclosed spaces shall be repeated continuously . The repetition is necessary because these accidents account for a number of deaths among seafarers every year.

The atmosphere of any enclosed or confined space may put at risk the health or life of any person entering. It may be deficient in oxygen and/or contain flammable or toxic fumes, gases or vapours. Such an unsafe confined space may include: –

a) Cargo holds, double bottom tanks, cargo tanks,

b) Pump rooms, compressor rooms,

c) Fuel tanks, ballast tanks, cofferdams,

d) Void spaces, duct keels, inter-barrier spaces,

e) Sewage tanks, cable trucks, pipe trunks,

f) Pressure vessels,

g) Battery lockers,

h) Chain lockers,

I) Inert gas plant scrubber and blower spaces and

j) Storage rooms for CO2, halons and other media used for fire extinguishing or inerting.

k) Unused store lockers

Should there be any unexpected reduction in or loss of the means of ventilation to the spaces that are continuously or adequately ventilated then such spaces should also be treated as enclosed spaces.

When it is suspected that there could be a deficiency of oxygen in any- space, or that toxic gases, vapours or fumes could be present, then such a space should be treated as a an enclosed space and adequate precautions taken.

Entering Dangerous spaces

Precautions should be taken as appropriate before a potentially dangerous space is entered to make the space safe for entry without breathing apparatus and to ensure it remains safe whilst persons are within the space.

No one should enter any dangerous space to attempt a rescue without first raising the alarm and taking suitable precautions for his own safety since not doing so would put his own life at risk and almost certainly prevent the person he intended to rescue being brought out alive.

Duties and Responsibilities

A competent person is a person capable of making an informed assessment of the likelihood of a dangerous atmosphere being present or arising subsequently in the space. This person should have sufficient theoretical knowledge and practical experience of the hazards that might be met in order to assess whether precautions are necessary.

This assessment should include consideration of any potential hazards associated with the particular space to be entered. The person should also take into consideration dangers from neighbouring or connected spaces and the work that has to be done within the space.

Any certificated officer can be appointed as a competent person provided the Master has ascertained that he is fully aware of the hazards and the procedures.

The assessment made by the competent person could fall in any one of these categories:

a) There is no conceivable risk to the life or health of a person entering the space then or at any future time, entry should therefore be permitted;

b) There is no immediate risk to health and life but a risk could arise.during the course of work in the space, entry should be restricted for specific periods;

c) The risk to life or health is immediate, entry must be under full precaution at all times and if the compartment contains explosive or poisonous atmosphere entry should be prohibited.

A responsible officer is a person appointed to take charge of every operation where entry into a potentially dangerous space is necessary. When the ship is in dry dock or carrying out extensive repairs the competent person or the responsible officer may be the same. In this case, both the competent person and/or the responsible officer may be a shore-side person. In every case, the ship’s responsible person shall still have the responsibility to ensure that the proper procedures are being followed.

Where the assessment shows that there is no conceivable risk to health or life and that, conditions in the space will not change; entry may be made without restriction. Similarly an assessment could be made that the risk is eliminated with no chance what so ever of it recurring. Entry thereafter could also be made without restriction.

Where the assessment shows that there is no immediate risk to health and life but that a risk could arise during the course of work in the space, the space should be considered dangerous. Permit to work thereafter is enforced and precautions described hereinafter shall be taken as appropriate.

Where the risk to life or health is immediate then all the requirements specified shall be complied.

Identifying Potential Hazards

Oxygen Deficiency

If an empty tank or other confined space has been closed for a time the oxygen content may have been reduced due to the oxygen combining with steel in the process of rusting.

Lack of oxygen may occur in boilers or other pressure vessels particularly where oxygen-absorbing chemicals have been used to prevent rusting. Depletion of oxygen may occur in cargo spaces when oxygen absorbing cargoes, (for example, oil cake and other vegetable and animal oil bearing products, certain types of wood cargoes, steel products, iron and steel swarf etc,) are or have been carried.

Oxygen deficiency can also be experienced in cargo holds when carrying ore concentrates even though the hatch covers have been removed and the discharge of cargo has commenced.

After discharge of volatile cargoes sufficient vapours may still remain in tanks to cause oxygen deficiency. Hydrogen may occur in cargo oil tank used for ballast but will tend to disperse quickly when tank covers are opened. Pockets of hydrogen may, however, still exist in the upper parts of the compartment, thus displacing the oxygen (as well as creating a possible explosion hazard). If carbon dioxide, steam or other fire-extinguishing chemical has been discharged to extinguish fire, the oxygen content of the space would be reduced. The use of inert gas in the cargo tanks of tankers and Gas carriers or in the inter-barrier spaces of a Gas carrier result in minimal amounts of oxygen being present.

Ullage spaces of cargo tank, cargo tanks, cofferdams, inter-barrier spaces and void spaces adjacent to tanks carrying reactive substances may have to be inerted.

Toxicity of Oil Cargoes

Hydrocarbon gases are flammable as well as toxic and may be present in fuel or cargo tanks, which have contained crude oil or its products.

Hydrocarbon gases or vapours may also be present in pump rooms and cofferdams, duct keels or other spaces adjacent to cargo spaces due to the leakage of cargo.

The components in the vapour of some oil cargoes, such as benzene and hydrogen sulphide are highly toxic.

Toxicity of other Substances

Cargoes carried in chemical tankers or gas carriers may be toxic. There is the possibility of risk due to leakage from drums of chemicals or other packages of dangerous goods when mishandling, incorrect stowage or damage due to heavy weather is suspected.

The trace component of gases in inert gas such as carbon monoxide, sulphur dioxide, nitric oxide and nitrogen dioxide are highly toxic.

The interaction of vegetables or animal oils or sewage with seawater may lead to the release of hydrogen sulphide gas, which is highly toxic. Hydrogen sulphide or other toxic gases may be generated where the residues of grain or similar cargoes permeates into or chokes bilge-pumping systems.

The chemical cleaning, painting or the repair of tank coating may involve the release of solvent vapours, which are often toxic.

Flammability

Flammable vapours may still be present in cargo or other tanks that have contained oil products or chemical or gas cargoes.

Cofferdams and other spaces that are adjacent to cargo and other tanks may contain flammable vapours should there have been leakage into the space, from the adjacent tank.

Other Hazards

Although the inhalation of contaminated air is the most likely route through which harmful substances enter the body, some chemicals can be absorbed through the exposed skin as well.

Some of the cargoes carried in chemical tankers and gas carriers are irritant or corrosive.

The disturbance of rust, scale or sludge residues of animal, vegetable or mineral origin, or of water that could be covering such substances may lead to the release of toxic or flammable vapours.

Preparing and Securing the Space for Entry

When opening the entrance to a dangerous space, care should be taken to avoid the effects of a possible release of vapour under pressure from the space.

The space should be isolated and secured against the ingress of dangerous substances by blanking off pipelines or other openings or by closing valves.

Valves should then be tied or some other means used to indicate that they are not to be opened.

If necessary, the space should be cleaned or washed out to remove as far as practicable, any sludge or other deposit liable to give off dangerous fumes. Special precautions may be necessary when carrying out this activity.

The space should be thoroughly ventilated by either natural or mechanical means to ensure that all harmful gases are removed and no pockets of oxygen deficient atmosphere remain. Compressed oxygen should not be used to ventilate any space.

The officers on watch on the bridge / in the cargo control room, and in the engine room should be informed, as necessary, of any space that is to be entered. This is to ensure that such officer does not take any action, which may harm the persons in the compartment entered. Such actions could be to stop fans, start equipment or open valves by remote control, close escape doors or pump cargo or ballast into the space. Appropriate warning notes should be placed on the relevant controls or equipment. Where necessary, pumping operations or cargo movements should be suspended when entry is being made into a dangerous space.

Testing the Atmosphere of the Space

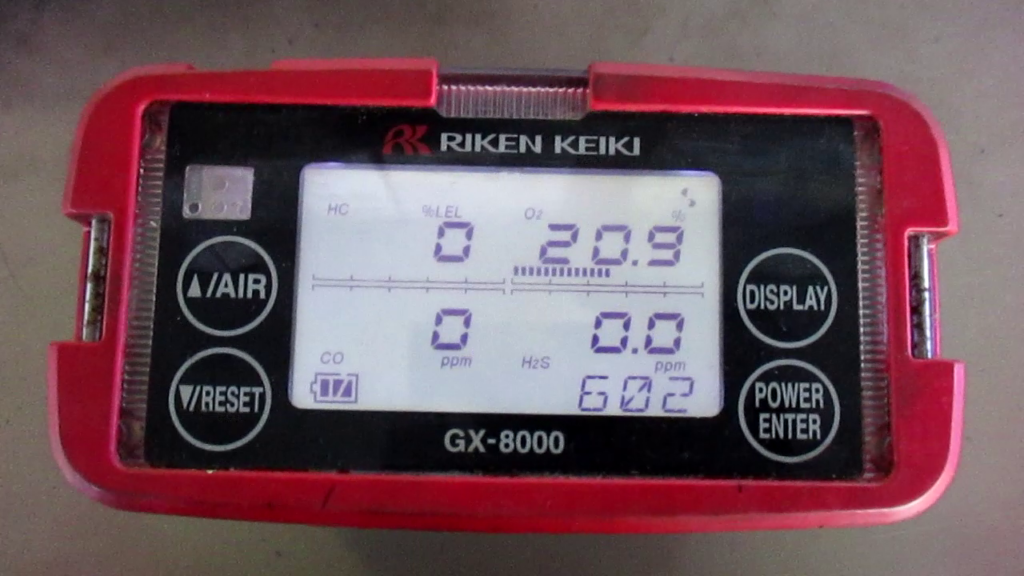

► Only persons trained in the use of the testing equipment should carry out testing of a space.

► Testing should be carried out before entry and at regular intervals thereafter.

► If possible, the testing of the atmosphere before entry should be made by remote means. If this is not possible, the person selected to enter the space to test the atmosphere should only do so in accordance with the additional precautions specified herein, including the wearing of breathing apparatus.

► Where appropriate, the testing of the space should be carried out at different levels.

► Personal monitoring equipment designed purely to provide a warning against oxygen deficiency and hydrocarbon concentrations should not be used as a means of determining whether a dangerous space is safe to enter.

Testing for Oxygen Deficiency

► A steady reading of at least 20% oxygen by volume on an oxygen content meter must be obtained before entry is permitted.

► A combustible gas indicator cannot be used to detect oxygen deficiency.

Testing for Flammable Gases or Vapours

The combustible gas indicator (also called the `Explosimeter) detects the amount of flammable gas in the air. An instrument capable of providing an accurate reading at low concentrations should be used to judge whether the atmosphere is safe for entry.

Combustible gas detectors are calibrated on a standard gas and when testing for other gases and vapours, reference should be made to the calibration curves supplied with the instrument. Particular care is required should accumulations of hydrogen be suspected.

A ‘nil’ reading on a suitably sensitive combustible gas indicator is desirable in deciding whether the atmosphere is safe to work in without being overcome. However, where the readings have been steady up to 1 % of lower flammable limit for some time, the conditions may be accepted as safe. (e.g. for hydrocarbons in conjunction with an oxygen reading of at least 20% by volume.)

Direct measurement of trace components of inert gas is not required when gas freeing a cargo tank, particularly when, the hydrocarbon concentration is reduced from about 2% by volume to 1% of lower flammable limit or less with a steady oxygen reading of at least 20% by volume. This is sufficient to dilute the components to a safe concentration. If, before the commencement of gas freeing, the hydrocarbon concentration of a tank containing inert gas is below 2% by volume due to excessive purging by inert gas, then additional gas freeing is necessary to remove toxic products introduced with the inert gas. It is difficult to measure the quantities of these toxic products at the safe level without specialised equipment and trained personnel. If this equipment is not available for use the period of gas freeing must be considerably extended.

Testing for Toxic Gases

The presence of certain gases and vapours on chemical tankers lead to highly complex toxic conditions, which though can be measured on board, it is very difficult to determine the occupational exposure limits. Such presence shall be treated with caution and entry prohibited.

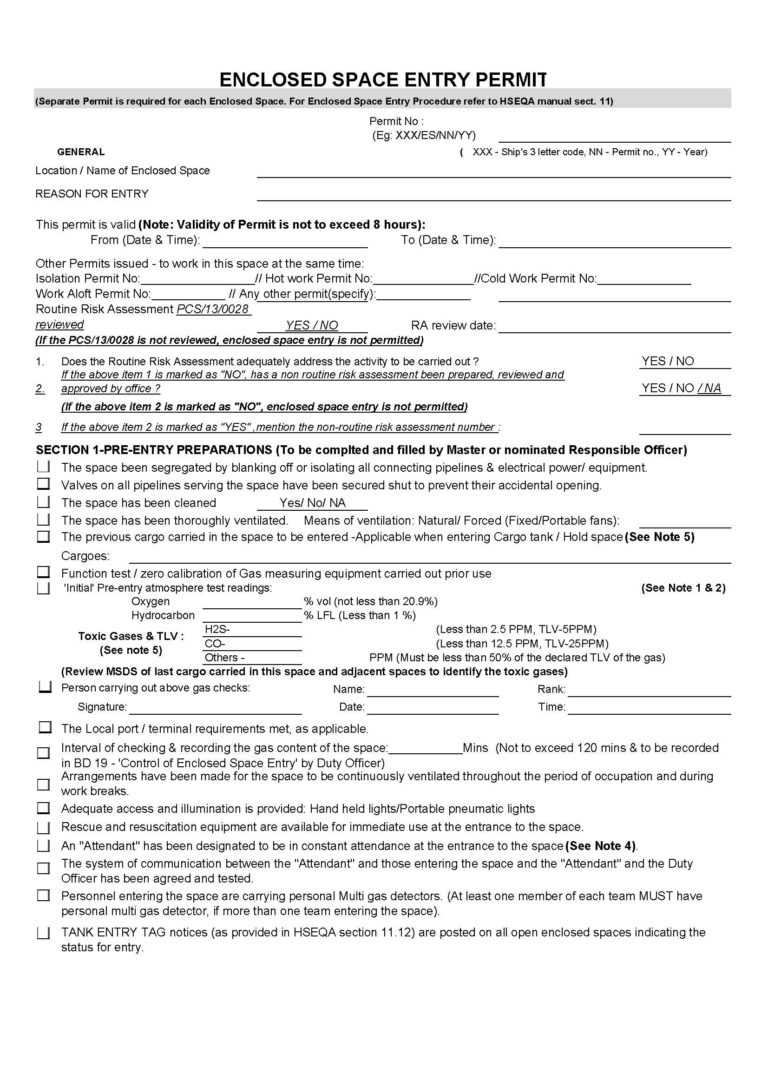

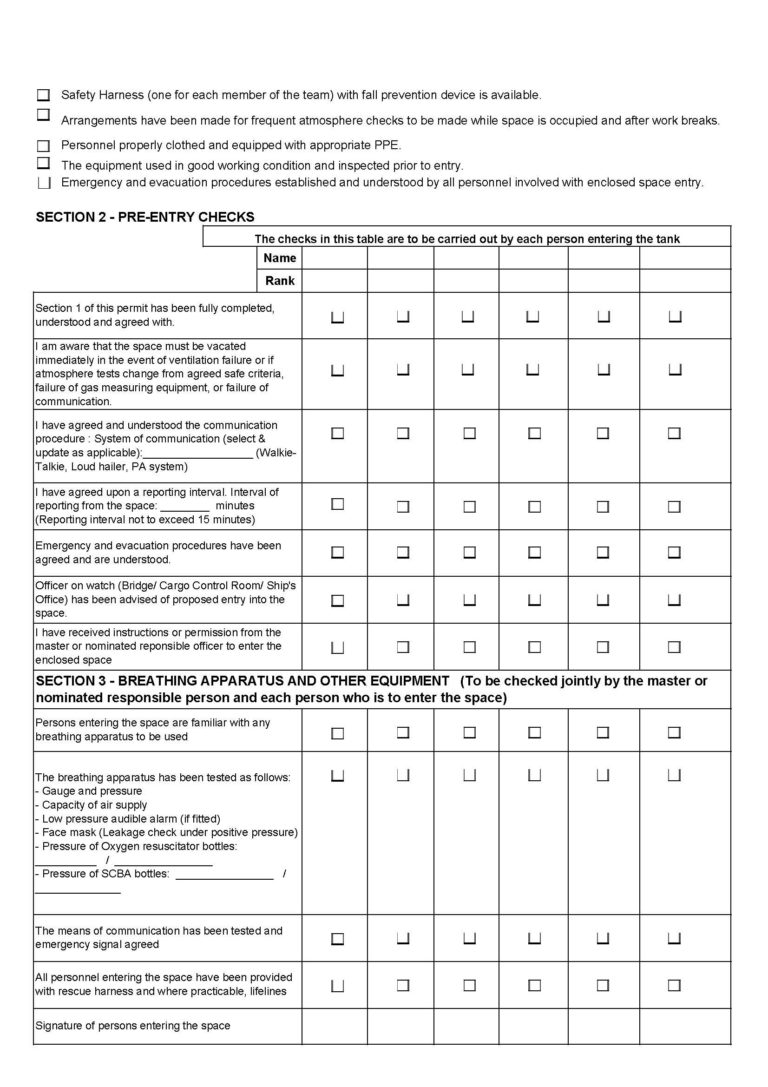

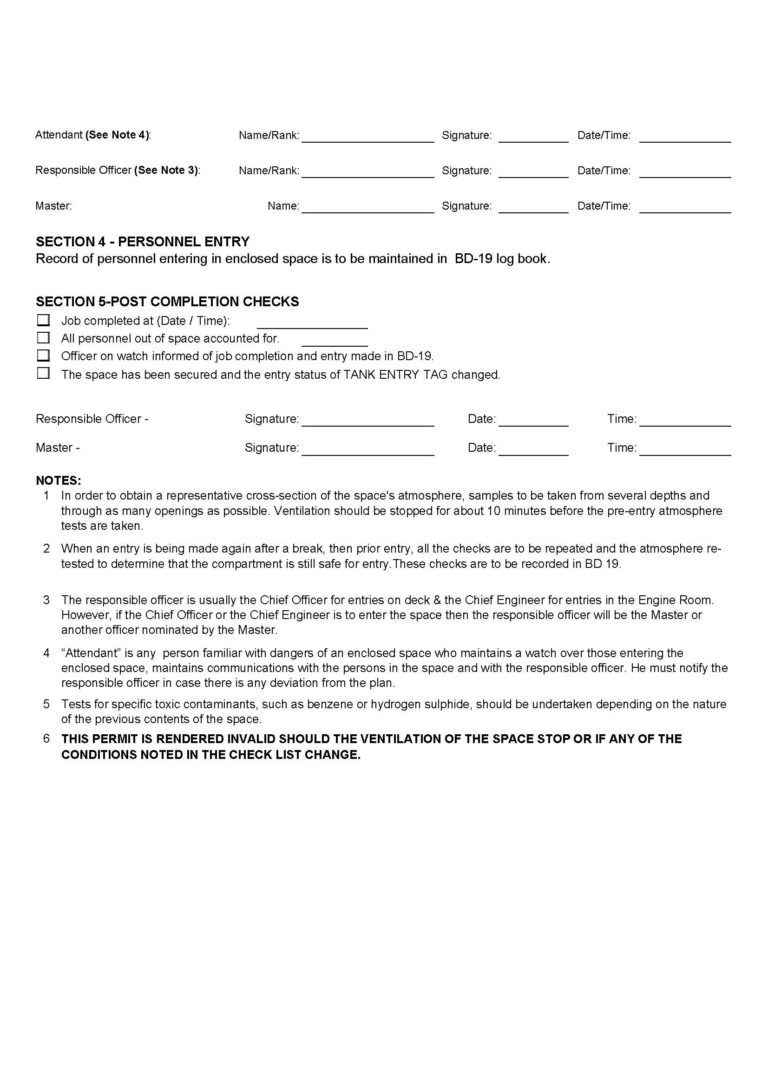

Use a Permit-to-Work System

Entry into a dangerous space should be planned and use should be made of a ‘permit-to-work’ system. If, during the course of the operations, unforeseen difficulties or hazards develop, the work should be stopped and the space evacuated so that the situation can be fully assessed, afresh and corrected. Permits would be withdrawn and issued only after the situation has been reassessed. ‘Permits-to-work’ procedures are revised as appropriate. Written instructions are issued to give details of the arrangements to be followed in a ‘permit-to-work’ system.

Check list are to be used as ‘aide memoir’ for which a well-established safety system of work exists, a checklist may be used to ensure that all precautions are taken if the person using the check list is fully aware of the principles and practice of the ‘permit-to-work’ system.

On expiry of the ‘permit-to-work’, everyone should leave the space, the entrance to the space should be closed or otherwise secured against entry and a warning notice placed. Where the space is no longer a dangerous space, the fact shall be recorded in the deck log and the notices etc. removed.

Procedures and Arrangements before Entry

► Access to and from the space should be adequate and well illuminated.

► No matches, welding or flame cutting equipment, electrical equipment or other sources of ignition should be taken or put into the space unless the master or the responsible officer is satisfied that it is safe to do so.

► In all cases, rescue and available resuscitation equipment should be positioned, ready for use at the entrance to the space. Rescue equipment means breathing apparatus together with fully charged spare air cylinders, and lifelines. Rescue harnesses, and torches or lamp, approved for use in rescue of incapacitated person from the confined space, must also be readily avalaible where appropriate.

► The number of persons entering the space should be limited to those who actually ‘need to work in the space and who could be safely and positively rescued should an emergency occur.

► At least one attendant should be detailed to remain at the entrance to the space whilst it is occupied.

► A system of communication should be agreed and tested by all involved to ensure that any person entering the space can keep in touch with the person stationed at the entrance.

► A system of communication should be established between the attendant at the entrance to the space and the officer on watch.

► Before entry is permitted, it should be established that entry with breathing apparatus is possible. The extent to which the use of breathing apparatus or life lines or rescud. harnesses would cause any difficulty of movement within any part of the space, or would cause problems if any incapacitated person has to be removed from the space, should also be examined.

► Lifelines of rescue harnesses should be long enough for the purpose and be easily detachable by the wearer, should they become entangled but should not otherwise come away from the rescue harness on their own.

Procedures and Arrangements during Entry

► Ventilation should continue during the period that the space is occupied and during temporary breaks. In the event of a failure of the ventilation system persons in the space should leave immediately.

►If unforeseen difficulties or hazards develop, the work in the space should be stopped and the space evacuated so that the conditions can be reassessed. ► If a person in a space feels in any way adversely affected, he should give the prearranged signal to the attendant standing by the entrance and immediately leave the space.

►When available a rescue harness should be worn to facilitate recovery in the event of an accident.

► If an emergency occurs, the general (or crew) alarm should be sounded so that back up is immediately available to the rescue team.

►If unforeseen difficulties or hazards develop, the work in the space should be stopped and the space evacuated so that the conditions can be reassessed.

► If a person in a space feels in any way adversely affected, he should give the prearranged signal to the attendant standing by the entrance and immediately leave the space.

►When available a rescue harness should be worn to facilitate recovery in the event of an accident.

► If an emergency occurs, the general (or crew) alarm should be sounded so that back up is immediately available to the rescue team.