Code of Federal Regulations (CFR) requires tanker vessels to issue a vapour tightness certificate with the code. This is to be documented using the form “T 3 – Vapour Tightness Certificate”.

Following method should be used for the purpose of carrying out the test:

P/V Valve to be checked for proper functioning prior doing this test.

Keep all openings shut.

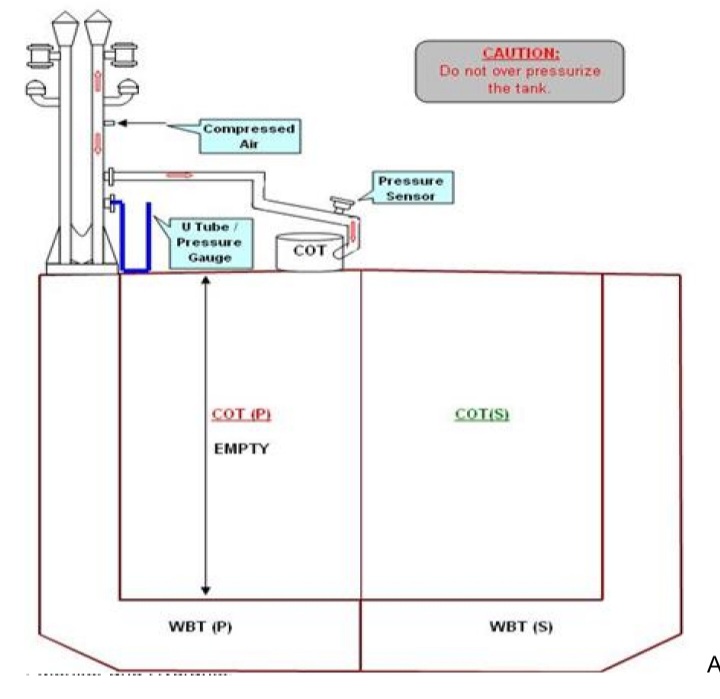

Install a U-Tube or a Compound Gauge on the PV Stack

Pressurize tank using Compressed Air or Nitrogen

Let the tank pressure come up to 1250 mm WG but no more than the pressure of the lowest pressure relief valve setting.

Openings to be checked for leakage using Soap solution (Apply soap solution to all openings, flanges and welding seams – leakage will be visible by means of soap bubbles.

Once the pressure is obtained, the dry air or inert gas source shall be shut off.

At the end of one-half hour, the pressure in the Cargo tank and piping shall be measured. The change in pressure shall be calculated using the following formula:

P=Pi-Pf

Where:

P=change in pressure, inches of water.

Pi=pressure in tank when air / gas source is shut off, inches of water.

Pf=pressure in tank at the end of one-half hour after air / gas source is shut off, inches of water.

The change in pressure, P, shall be compared to the pressure drop calculated using the following formula:

PM=0.861 Pi L/V

Where:

PM=maximum allowable pressure change, inches of water.

Pi=pressure in tank when air / gas source is shut off, psi.

L=maximum permitted loading rate of vessel, barrels per hour.

V=total volume of product tank, barrels.

If P < PM, the vessel is vapour tight.

If P>PM, the vessel is not vapour tight and the source of the leak must be identified and repaired prior to retesting.

In order to maintain vapour tightness the following should be checked and maintained in good condition.

a. Packings on tank domes, butter worth openings, level gauge fittings.

b.Tank securing arrangements.

c.Cargo valve and drain valve integrity.

d.P/V valves.

e.Vapor locks.