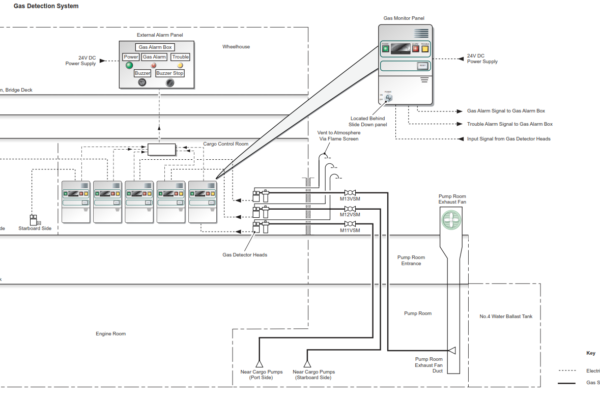

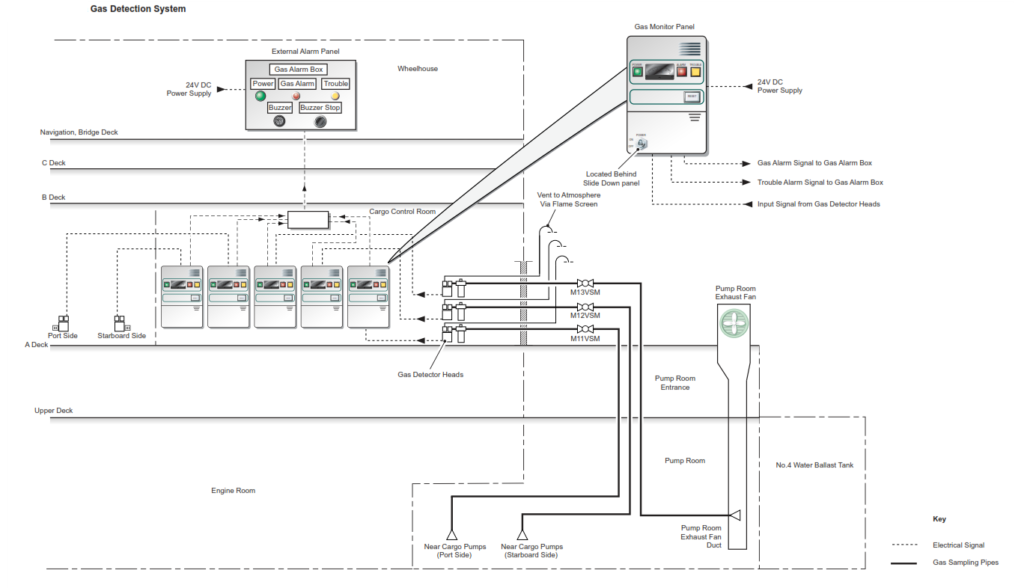

The Gas Sampling system is a gas detection system which monitors and detects explosive gases in the pump room. The system monitors for hydrocarbon content. Additionally, there are two gas sampling points in the accommodation, one at each entrance door on ‘A’ deck.

The gas detection system is an automatic scanning, permanently installed gas detection system, continually monitors the following three sampling points:

• Near the cargo pumps on the port side

• Near the cargo pumps on the starboard side

• In the pump room exhaust fan duct

• Accommodation entrance, port side

• Accommodation entrance, starboard side

The gas detection system consists of four primary units:

Gas Detector Heads

The gas detector heads for the pump room are located behind the cargo control console in the cargo control room and contain the sample pump and sensor. The gas detector head pump draws the sample through the sensor, where the sample is preheated so that catalytic combustion occurs. The change in the electrical resistance of a platinum filament, due to the generated heat, is detected on a wheatstone bridge circuit in the sensor.

The resultant electrical output is directly proportional to the concentration of combustible gas in the sample and is sent to the gas monitor.

Gas Monitors

The gas monitors are also located in the cargo control room and contain the following

• Display dial to show the lower explosive limit LEL concentration level of the sample

• Power LED which lights when the 24V DC electrical supply is available

• Alarm LED which lights when the LEL reaches 30%

• Trouble LED which lights when the LEL approaches 30%

• Buzzer alarm

• Reset pushbutton to reset the gas monitor when the LEL concentration goes below 30%

• The following switches inside the front cover

- Power On/Off switch

- Test switch for checking the alarm set points

- Maintenance switch for testing the external alarms, which should be operated together with the test switch

The gas monitor sends a signal to the alarm panel when the LEL reaches 30%.

External Alarm Panel

The function of this panel is to indicate alarms visually and audibly on the bridge.

Pipe System

The copper pipe system transports the samples from the sampling points in the pump room to the detector heads and incorporate shut-off valves and flame traps, which are located on the deck area above the pump room forward of the accommodation.

It is important that the sample supply to the system is never isolated during the normal operation of the detector heads. The individual sampling line isolation valves must also remain open during normal sampling operations.