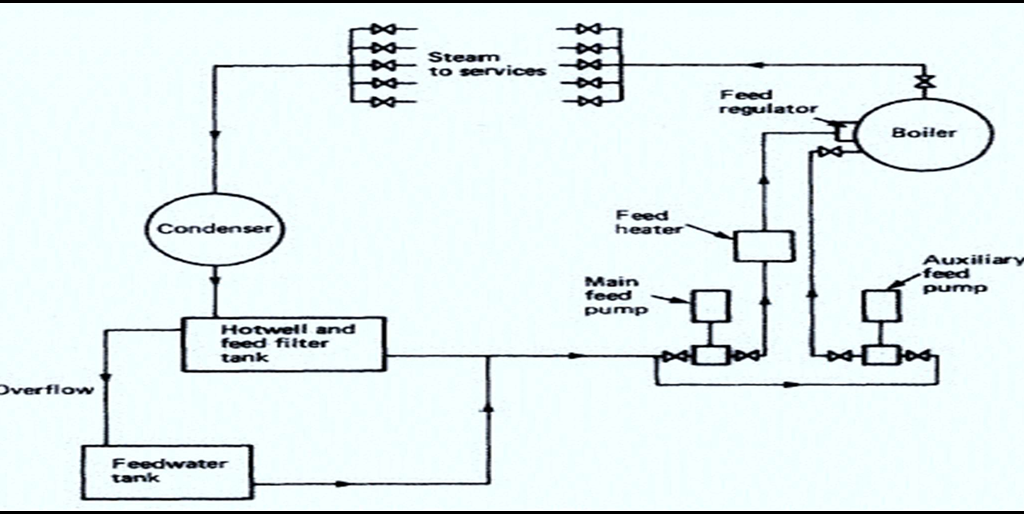

Open feed water system used for boilers and line diagram of a complete feed water system for an auxiliary boiler showing the direction of flow in all lines. How the feed supply to the boiler is regulated.

- The exhaust steam from the various services is condensed in the condenser.

- The condenser is circulated by sea water.

- The condensate then drains under the action of gravity to the hot-well and feed filter tank.

- Where the condenser is under an amount of vacuum, extraction pumps will be used to transfer the condensate to the hot well.

- The hot well will also receive drains from possibly contaminated systems, e.g. fuel oil heating system, oil tank heating, etc.

- The feed filter and hot well tank is arranged with internal baffles to bring about preliminary oil separation from any contaminated feed or drains.

- The feedwater is then passed through charcoal or cloth filters to complete the cleaning process.

- Any overflow from the hot well passes to the feedwater tank which provides additional feedwater to the system when required.

- The hot well provides feedwater to the main and auxiliary feed pump suctions.A feed heater may be fitted into the main feed line.

- This heater may be of the surface type, providing only heating, or may be of the direct contact type which will de-aerate in addition.

- De-aeration is the removal of oxygen in feedwater which can cause corrosion problems in the boiler.

- A feed regulator will control the feedwater input to the boiler and maintain the correct water level in the drum.

Advantages and disadvantages of water tube boiler and Smoke tube boiler

Advantages of water tube boiler:

- Higher Efficiency: Water tube boilers generally offer higher thermal efficiency compared to smoke tube boilers, resulting in improved fuel utilization and reduced fuel consumption.

- Enhanced Heat Transfer: The design of water tube boilers facilitates better heat transfer due to a larger surface area and higher water circulation rates.

- Faster Steam Generation: Water tube boilers are capable of producing steam quickly, allowing for faster startup times and rapid response to changes in steam demand.

- High Pressure Capability: Water tube boilers can handle higher steam pressures, making them suitable for applications requiring high-pressure steam, such as marine propulsion systems.

- Improved Safety: Water tube boilers have a lower risk of catastrophic explosions since the water is contained within the tubes, which can handle higher pressure compared to the outer shell.

- Flexibility in Design: Water tube boilers can be designed and customized to suit specific ship requirements, such as varying power demands, space constraints, and operational needs.

- Compact Size: Water tube boilers are generally more compact than smoke tube boilers, providing space-saving advantages on board ships.

- Lower Weight: Water tube boilers tend to have a lower weight-to-steam-output ratio, making them suitable for applications where weight considerations are critical, such as in smaller vessels.

- Ease of Inspection and Maintenance: Water tube boilers offer better accessibility for inspection, maintenance, and cleaning of internal components, leading to easier upkeep and reduced downtime.

Disadvantages of water tube boiler:

- Drums exposed to heat, increasing the risk of explosion

- Large water volume, resulting in poor circulation

- Limited steam pressure and evaporation.

Advantages of Smoke Tube Boiler:

- Less space is taken for the same output.

- Steam can be raised from cold water in a few hours, since there is a natural circulation of water.

- Stresses can be reduced due to the natural circulation of water when lighting up.

- Steam and water drums are small in diameter, compared with large shell of scotch boiler.

- Less mass of water is carried compared to scotch boiler, hence there is saving in weight.

- Rapid heat transmission

- Fast reaction to steam demand

- High efficiency

- Safer than firetube boilers

Disadvantages of smoke tube boiler:

- More control than fire tube boilers

- Higher initial cost

- More complicated to operate.

The importance of maintaining boiler water to certain standards? How poorly maintained water in the boiler can damage the boiler?

- High pressure, high temperature boilers with their large steam output require very pure feedwater.

- Even the pure water will contain some dissolved salts.

- These salts then adhere to the heating surfaces as a scale and reduce heat transfer, cause local overheating and failure of tubes.

- Other salts remain in solution and may produce acids which will attach to the metal of the boiler.

- The presence of dissolved oxygen and carbon dioxide in boiler feedwater can cause considerable corrosion of the boiler and feed system.

- When boiler water is contaminated by suspended matter, an excess of salts or oil then foaming may occur.

- Foaming leads to priming which is the carry-over of water with the steam leaving the boiler drum.

- Any water present in the steam entering a turbine will do considerable damage.

Why boiler water test is necessary and which tests are carried out. For each test normally carried out, state (i) Reasons for making the test, (ii) Acceptable values for any particular type of auxiliary boiler.

Reason for Boiler water tests:

- To prevent scale formation in the boiler.

- Prevent corrosion in the boiler feed system by maintaining the boiler water’s alkaline condition.

- Improving efficiency and reduced maintenance.

Boiler water tests:

pH (Acidity/Alkalinity):

Purpose: Determines the acidity or alkalinity of the boiler water, which can affect corrosion rates and chemical treatment effectiveness.

Typical Value: The ideal pH range for boiler water is typically between 9.5 and 11.5, ensuring alkaline conditions for corrosion protection.

Phosphate test and hydrazine test:

Purpose:

- To determine the phosphate content.

- Phosphate level is important to maintain as it reacts with calcium impurities within the water and forms a precipitate that will accumulate at the bottom of the boiler.

- This can later be blown down by boiler blow down valve.

Typical Value: 20 to 50 ppm

Hydrazine Test:

Purpose:

Hydrazine level is maintained so that oxygen reacts with hydrazine and forms hydrogen and water. Typical Value: 0.1 to 0.2 ppm

Chloride test:

Purpose: Determines the chloride ion concentration in the boiler water, which can cause corrosion and foaming issues.

Typical Value: Chloride levels should be maintained below specific limits depending on the boiler type and water treatment requirements. Typical values range from 200 to 300 ppm.

Conductivity test:

Purpose: Measures the electrical conductivity of the boiler water, providing an indication of the overall mineral content.

Typical Value: Conductivity levels can vary based on boiler type and operating conditions. However, typical values range from 2,000 to 5,000 μS/cm (micro siemens per centimetre).

Total Dissolved Solids (TDS):

Purpose: Measures the concentration of dissolved solids in the boiler water, indicating the level of impurities.

Typical Value: Recommended TDS levels vary depending on boiler type and operating conditions. However, typical values range from 2,000 to 3,500 ppm (parts per million).

Action required when measured values differ appreciably from desired values when testing of boiler feed water?

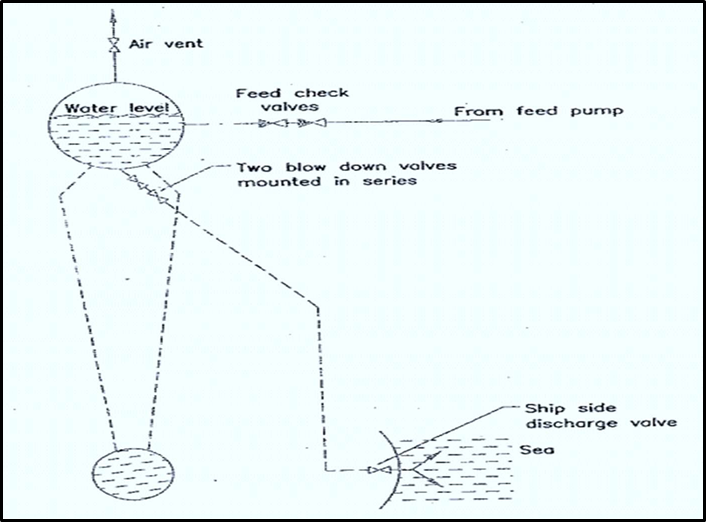

Boiler Blow Down:

- Boiler blow down is done on a regular basis determined from boiler water tests, to prevent excessive sludge build-up, as a result of chemicals used for dosing.

- Blow down is the mechanical process of removing boiler water to lower excessive concentration of dissolved and suspended solids, in boiler water.

- The excessive accumulation of sludge and scale reduces heat transfer rates and can cause local over-heating and failure.

- Blow down is carried out by boiler blow down valve.

Blow down valve:

- Consists of two valves mounted in series.

- First valve must be full open before the second can be cracked open i.e. sufficient to give the required rate of blow down.

- In this way the seating of the first valve is protected from damage, so reducing the risk of leakage when the blow down valves are closed.

- These blow down valves discharge into a blow down line, leading to a ship-side discharge valve.

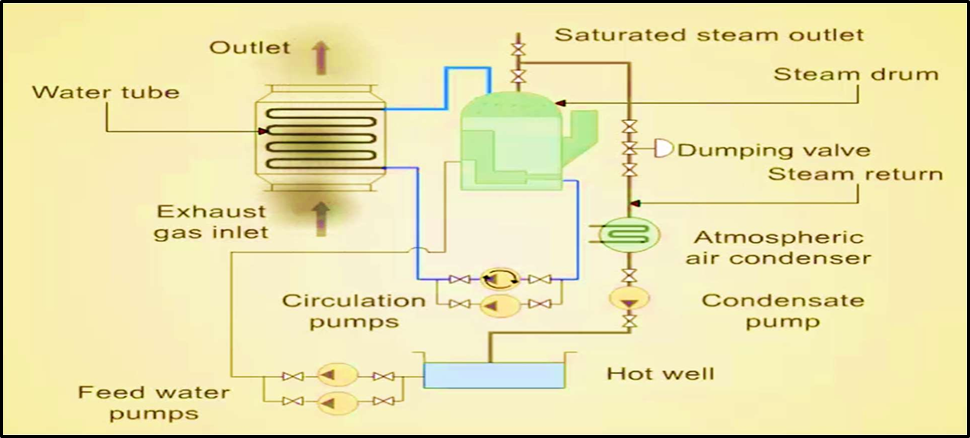

Water tube exhaust gas economizer

- This is also called as forced circulation multi loop type boiler.

- On board ships where the large quantity of steam is required from waste heat recovery system, the exhaust gas economizer is fitted in the main engine up take.

- Separate oil-fired boilers are required to supply steam when main engine is not running.

- Circulating pumps enforces forced circulation of the feed water by taking feed water from oil fired boiler.

- And discharges this water in to the exhaust gas heat exchangers tubes to receive heat from main engine exhaust.

- Steam drum from auxiliary boiler receives the steam produced from exhaust gas heat exchanger

- It also receives the steam produced by oil-fired boiler.

- The amount of steam produced is controlled by amount of heat from exhaust flowing through the exhaust up take or dumping the excess steam produced into the condenser.

Means provided to prevent oil contamination of the feed water

Feed water Filters:

- The function of a feed water filter is to extract oil and other impurities from the water before it is fed into the boiler.

- Any small quantities of oil which might be carried into the boiler could become a great danger, it is a poor conductor of heat.

- A patch of oil on a heating surface can cause over-heating of that part with consequent loss of strength and collapse.

- The filters are usually fitted in the discharge line of the feed pumps.

- A common type consists of perforated cylinders. The cylinders are wrapped with closely woven cloth towelling.

- The water is forced through from the outside to the inside of the cylinders.

- The filter connections have by-pass valves to enable the filtering medium to be taken out and renewed and cleaned at regular intervals.

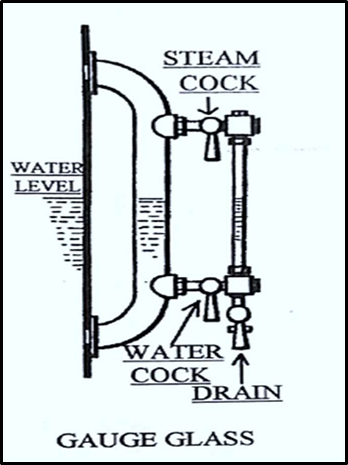

Blowing through procedure of boiler water gauge glass

- Shut the steam and water cocks, open the drain to drain out the contents in the line.

- Crack open the steam cock only and see whether steam is coming out from the drain. Then close the steam cock.

- Now open the water cock and see whether water is coming out from the drain. Then close the water cock.

- This indicates that passage is clear.

- Now shut the drain cock and open the water cock. The water should rise to the full height of the gauge glass.

- Now open the steam cock and now the level should come down to the correct level.