The Harmonized System Of Survey and Certification (HSSC)

Previously the certificates were issued on different dates when the relevant certificates expired. They had different periods of validity. When their annual and other surveys became due, preparations had to be done for each. Often preparations were duplicated, because items for inspection under different surveys overlapped. Thus ship’s officers were constantly under pressure and required to prepare the ship for survey all the time. To avoid this extra effort and to bring about an orderly management of surveys, inspections and maintenance of ships IMO proposed the “harmonized” system as explained below.

The system came into force on 1st Feb 1992,when it was ratified by 15 member states, representing 50 % of the world’s merchant tonnage. The features of the new system are: –

The Harmonised system applies to the Statutory certificate viz.,

■ Passenger Ships Safety Certification, including Record of Equipment.

■ Cargo Ship Safety Construction certificate,

■ International Load Line Certificate,

■ International Oil Pollution Prevention Certificate,

■ Cargo Ship Safety Equipment Certificate, including Record of Equipment.

■ Cargo Ship Safety Radiotelegraphy/Radiotelephony Certificate,

■ Certificate of Fitness for carriage of Chemicals and Certificate of Fitness for carriage of gas.

Exemption certificates issued for the above have the same requirements

All statutory certificates for a particular ship are issued on a date called the anniversary date. Thereafter the anniversary dates remains the same for the five-year period for all such surveys during that period.

All certificates are issued for a 5-year validity period with annual endorsements. The passenger ships Safety Certificate has not been changed and will have a validity of one year as at present.

Cargo Ship Certificates will have a maximum validity. Of 5 years, subject to annual and intermediate surveys. Annual surveys are carried out ± 3 months of the Anniversary date and the Intermediate surveys ± 6 months of the halfway date of the certificate. Thus the Intermediate survey will be carried out, together with the second or third annual survey. The word ‘Anniversary’ can only now be used for the ship, as there is only one date of issue of certificates.

The first survey, which a ship undergoes, is the initial survey. The date of completion of all the surveys will be the date of issue of each certificate.

A Renewal survey must be carried out, between 3 months before to the date of expiry of the certificate. The renewal survey, which would have taken place under the old system for certificates, which had a validity of less than 5 years, is now replaced by the Annual or Intermediate survey, and is called a Periodical survey.

■ On the anniversary date, the ship undergoes either an annual survey or a renewal survey.

■ All statutory surveys have the same anniversary date and they must be carried out in a window of ± three months

■ Underwater inspection and / or dry-docking is carried out at the intermediate survey, which can take place between the second and the third anniversary date

■ The Cargo ship Safety Construction Certificate, Safety Equipment Certificate and Safety Radiotelegraphy/Telephony certificate are replaced by one certificate called the ‘Cargo Ship Safety certificate’. However, if the ship owner so desires, he may opt for separate certificates.

Classification Surveys

Continuous Machinery Survey (CMS)

This provides advantages to the ship owner. In this system, the ship owner does not have to dismantle equipment and hold up the vessel every year and every 5 years, for the purpose of Classification society surveys. Instead different items are dismantled and inspected on a continuous basis during the period of 5 years at the ship owner’s convenience, at specific intervals, While the ship is in port, such that Over the 5-year period, all items are inspected at the required intervals

The Classification society provides a quarterly report to the ship, of the items that are due for survey during that quarter. These items are opened up and presented to the surveyor for inspection, when the ship is in port. Any item not shown or not passed is carried forward to the next quarter.

A report of the survey in a port is communicated to the head office of the Classification society. The ship’s status of survey is updated in the Classification society’s database, so that the surveyor at the next port has an updated report of the ship’s survey status including pending inspections, qualifications and issues of interim certificates.

Annual Surveys - Under Class

General

■ Annual Surveys are to be carried out within 3 months of the due date each year. These are held concurrently with statutory Surveys,

■ Examine generally the ship and machinery, so far as necessary and practicable, in order to be satisfied as to their general condition for maintenance of the ship in class.

Survey Requirement - All Vessels

■ The surveyor is to thoroughly examine the following parts and also ensure the efficient condition of their respective closing appliances: a. Weather deck.

b. Hatchways on freeboard and superstructure decks; ventilators and air pipe coamings; exposed casings; skylights and openings; deck houses; companionways and superstructure bulkheads; side; bow and stern doors; side scuttles and dead lights; flush deck scuttles; ash shoots and other openings.

c. Scuppers and sanitary discharges together with valves and their controls.

d. Guard rails, bulwarks, freeing ports, gangways and lifelines, fittings and appliances for timber cargo.

■ Steel hatch covers with gasket fitted for weather tightness to be tested or alternatively to be proven tight.

■ Watertight doors in watertight bulkheads, to be examined and tested (locally and remotely).

■ To confirm that no significant changes have been made to the arrangements of structural fire protection.

■ Operation of manual and /or automatic fire doors where fitted.

■ Anchoring and mooring equipment.

■ Freeboard and draft marks on the ship’s side.

■ General examination of the machinery and boiler spaces with particular attention to the propulsion system, auxiliary machinery and the fire and explosion hazards.

■ To ensure that emergency escape routes are not blocked.

■ Main and auxiliary steering arrangements and their associated equipment and control systems. Inspect log entries relating to the steering exercises and use of auxiliary steering gear.

■ Chains used in Steering gear are to be cleaned for wear and tear to be ascertaining. Lengths of chain worn in mean diameter by more than 11 % of the original diameters are to be tested.

■ The bilge pumping systems and bilge wells including operation of pumps, extended spindles and level alarms, where fitted,

■ External examination of boilers, pressure vessels and their appurtenances including safety devices, foundations, controls, relieving gear, high pressure and steam escape piping, insulation and gauges,

■ To confirm that boilers and other pressure vessels have been tested at specified intervals.

■ General examination visually and in operation of the electrical machinery, the emergency sources of electrical power, the switchgear and other electrical machinery.

■ The operation of the emergency source •of power in automatic mode, if fitted.

■ The arrangements for the fire protection, detection and extinction are inspected under Sofas Chapter 11 regulations for issue of Cargo Ship Safety Equipment Certificate, including Record of Equipment on behalf of the national administration if so authorised.

Such examination include:

a. Verification that fire control plans are properly posted,

b. Examination of the fire and/or smoke detection system(s);

c. Examination of the fire main system and verification that each fire pump including the emergency fire pump can be operated separately so that the two required powerful jets of water can be produced simultaneously from different hydrants;

d. Verification that fire hoses, nozzles, applications and spanners are in good working condition and situated at their respective locations;

e. Examination of fixed fire fighting system controls, piping, instructions and marking, checking for evidence of proper maintenance and servicing, conducting random check for evidence of discharged containers;

f. Verification that all semi-portable and portable fire extinguishers are in the their stowed position, checking for evidence of proper maintenance and servicing, conducting random check for evidence of discharged containers;

g.Verification, as far as practicable, that the remote controls for stopping fans and machinery and shutting of fuel supplies in machinery spaces are in working order;

h. Examination of the closing arrangements of ventilators, funnel annular spaces, skylight, doorways and tunnel, where applicable;

i. Verification that fireman’s outfits are complete and in good condition.

(Surveys carried out by the National Authority of the country in which the ship is registered would normally be accepted as meeting these requirements, at the discretion of the surveyor)

■ Carry out Close — up survey and thickness measurement of structure identified at the previous Special Survey as having substantial corrosion.

■ Examination of Ballast tanks when required as a consequence of the results of the Special Survey or Intermediate Survey. When extensive corrosion is found, thickness measurement is to be carried out.

■ The surveyor is to confirm that, where required, approved loading instruments together with its operation manual are available on board. The operation of the loading instrument is to be verified.

■ For vessels having `UMS’ notation, General Examination of Automation equipment is carried out. Satisfactory operation of safety devices, bilge level detection and alarm systems and control systems are to be verified.

The Enhanced Hull Survey System

In view of the recent large number of losses of bulk carriers and the pollution caused by accidents to tankers, IMO has raised concern over the issue. A proposal to phase out vessels over 17 years of age has been resisted by ship owners, on the grounds that age is not the sole criteria that determine the condition of a vessel, especially if it is well maintained. An alternative response to the problem of an aging world fleet has been enhanced (more meticulous and stringent) hull surveys. This contains unified requirements to be adopted by all classification societies, while surveying tankers and bulk carriers. This contains unified requirements to the adopted by all classification societies, while surveying tankers and bulk carriers. The rules apply, regardless of size, to self-propelled oil tankers, product tankers and dry bulk cargo vessels including ore carriers and combination carriers.

The Features of the enhanced survey program are:-

The features of the enhanced survey program are

1. Survey Planning.

2. Document file on board.

3. improved procedures for thickness measurement.

4. Harmonisation between dry-dock and renewal surveys.

5. Extended Intermediate surveys.

6. Possible annual examination of tanks/spaces.

7. Phase-out of continuous Hull survey (CHS) arrangements.

The basic feature of the enhanced survey is extensive examination of the hull.

A ‘Close-up Examination’ is one where details of structural components are within the inspection range of the surveyor i.e. normally within reach of hand.

`Overall Survey’ is intended to report on the overall condition of the tank/hold/hull structure and determine the extent of additional close-up surveys.

Planning of Survey

It is expected that proper planning and co-operation between the owner and the Classification society will improve the quality of the survey. Cleaning, descaling and rigging proper means of access must carry out proper preparation.

Planning of the survey is done by two methods:

1. Mandatory Minimum Survey program.

This program is worked out for a ship, taking into account the mandatory minimum requirements for Overall examination close-up survey and thickness measurement that have been prescribed by the Classification society. Preparation to be carried out for the survey, such as access, cleaning/descaling, lighting,,gas freeing and survey equipment are also described

2. Survey based on Survey Planning Document

The survey-planning document identifies critical structural features, its operational features and its damage/repair history. It stipulates the location, extent and means of close-up examination of the areas.

Where a proper survey planning document is established for a ship, a provision exists for reduced examination of low risk areas, during the renewal survey, provided the condition of the vessel is good after inspection of the high risk areas. Initially the survey of these risk based areas may be less than the general survey, especially when the ship is new, but if deficiencies are found in these risk areas after the ship has spent some years in service, the extent of this survey may be more than the general or mandatory survey.

The Planning Document Contain:

The planning documents contain:

➢ Main particulars of the ship.

➢ Plan of tanks/holds with information on their use, cathodic protection and condition of coating.

➢ Corrosion risk nomination for close-up examination.

➢ Structures and sections nominated for thickness measurements.

➢ List of acceptable corrosion allowance for different structures.

Risk nomination is an assessment and evaluation of the risk of deterioration of Structures. It takes into account:

➢ Design features such as use of high tensile steel.

➢ Local details such as local stresses and local stress concentrations.

➢ History of the ship with regard to corrosion, buckling, cracking, repairs carried out to and spare parts used on that particular ship as well as sister ships.

➢ Information on the use of tanks and condition of the paint and cathodic protection on different ships from the office.

Document File

The document file is to provide those concerned with complete information about the structural condition of the vessel. It serves as the basis for the survey and includes:-

a) Survey report file containing

■ Hull survey reports

■ Hull summary.

■ Thickness measurement reports.

■ Survey planning document.

■ Supporting Documentation

■ Structural plans.

■ Cargo and ballast history.

■ Repair history.

■ Inspection and reports of ships’ personnel.

■ Use of IG plant.

Each part of the document file will be contained in a binder. The four parts of the survey Report file will each have a continuously updated index showing:

■ The Document file number.

■ Survey type (Annual, Intermediate, renewal, damage, Repair).

■ Date of survey.

■ Cross-references between survey reports and thickness measurement report.

A new binder is to be provided for each 5-year period. Old files are to be kept on board, for the lifetime of the ship, regardless of change in management or ownership. The document file will always be examined prior to structural surveys. They are to be readily available for reference to the vessel’s history and condition.

b) Corrosion and Coating

Criteria have been established to assess corrosion and to grade the condition of coating.

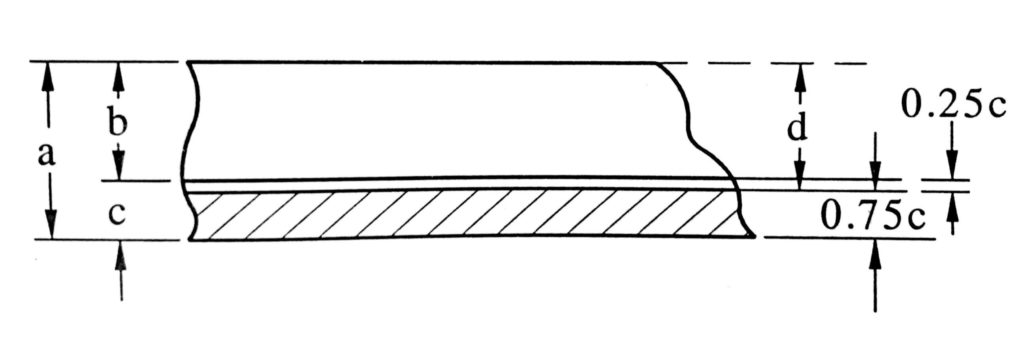

Substantial corrosion has been defined as an extent of corrosion, where the wastage is in excess of 75 % of allowable corrosion margins, but within acceptable limits.

The laying down of criteria implies that although mild corrosion can be detected visually, extensive and deep corrosion will have to be quantitatively evaluated by thickness measurements. These values will then be compared with a list of minimum thickness for the different structures of the vessel as prepared by the Classification society.

a: Dimension when new.

b: Acceptable minimum thickness

c: Acceptable maximum margin.

d. Substantial corrosion.

The condition of coating is defined as

Good: if there is only minor spot rusting.

Fair: If there is local breakdown of the coating at edges of stiffeners and weld connections and or light rusting over 20 % or so of the area under consideration.

Poor: If there is coating breakdown in general over 20% or more area on hard scale over 10 % area.

If the coating condition is found good, the classification society may reduce the extent of close-up measurement and thickness measurement but if the coating is poor, the tank may be subjected to annual inspection

Typical structural defects and their Locations

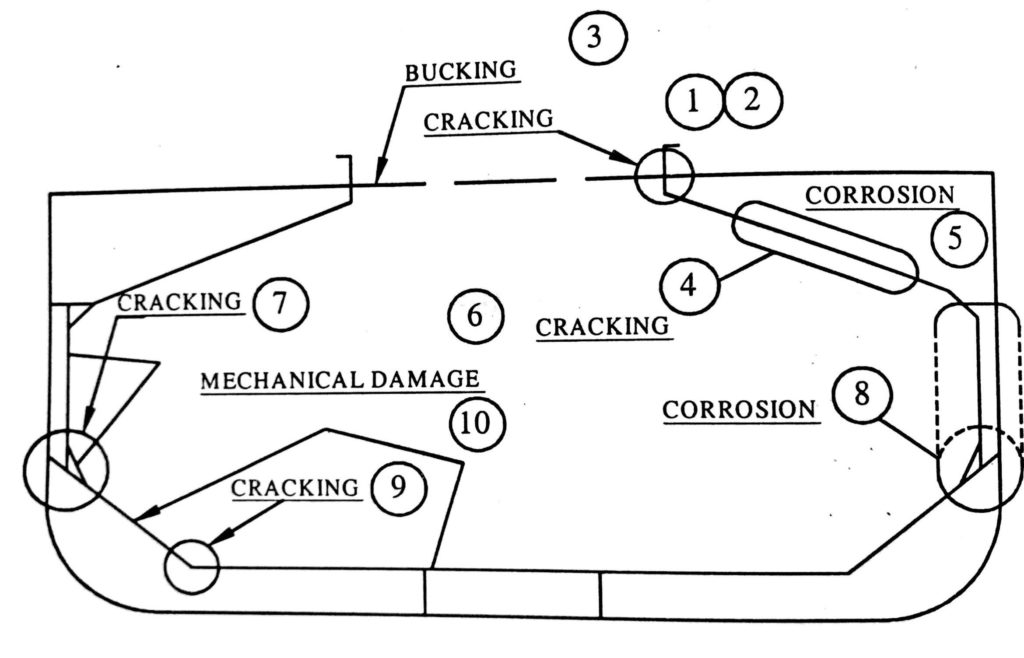

Typical structural defects and their locations (Bulk carrier)

1. Cracking of hatch covers.

2. Cracking of hatch coamings.

3. Plate panel buckling of cross deck strips and stiffening structure.

4. Cracking at fore and aft extremities of topside tank structure.

5. Corrosion within topside tanks and double skin.

6. Grab and bulldozer damage the main frame/lower bracket.

7. Cracking at main frame bracket toes.

8. Both general and localised corrosion of main ship’s side frames and brackets.

9. Cracking at the connection of the inner bottom and hopper plating.

10. Grab damage to the tank top plating, hopper and lower stool plating.

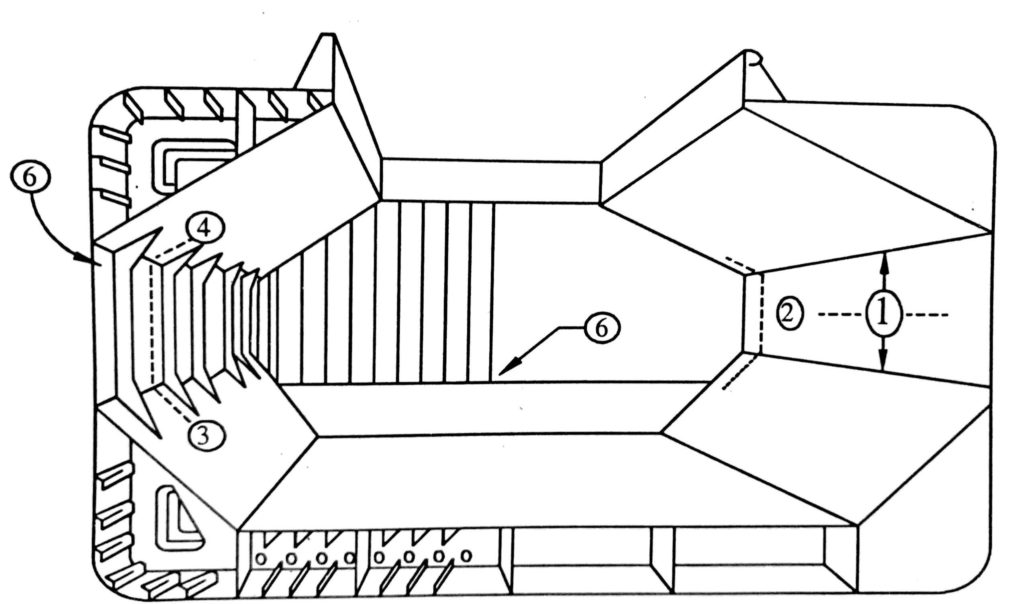

Where to look and what to look for

1. Side shell plating — Cracks, leaks and distortion.

2. Connection of side shell frame and end brackets to shell plating and hopper side tank plating — Cracks, corrosion, wastage, deformation and detached frames or brackets.

3. Connection of side shell frames and end brackets to shell plating and topside tank plating- Cracks, corrosion, wastage, deformation and detached frames or brackets.

4. Connection of side shell frames and end brackets to shell plating and topside tank plating Cracks, corrosion, wastage, deformation and detached frames or brackets.

5. Slant plate at junction of lower stool and corrugated bulkhead — Cracks, corrosion, wastage, leaks.

6. Connecting trunk between tanks, where fitted, – Cracks, corrosion, wastage and leaks.