Purpose of steering gear

The steering gear provides a movement of the rudder in response to a signal from the bridge to steer the ship.

Accidents because of steering gear failure are common in the maritime industry. Such incidents have led to some serious accidents in past, causing heavy damage to ship, its crew and the environment.

Overview of the Steering Gear

The direction of a ship moving through the water is controlled by changing the angle of rudder, located in the stern of the ship.

As the gross tonnage of ship increases, more and more force is required to move the rudder through the required angle.

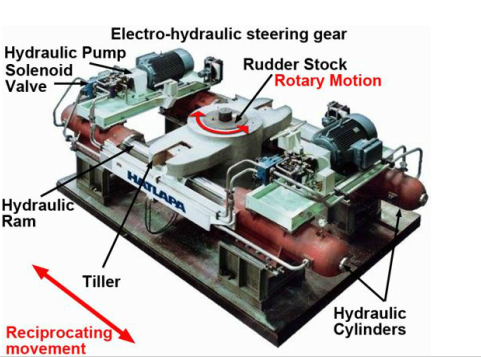

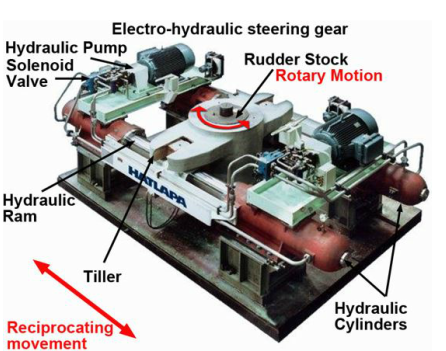

On a large ship, the power required to position the rudder is provided by electro hydraulic steering gear comprising of power units, hydraulic rams and cylinders.

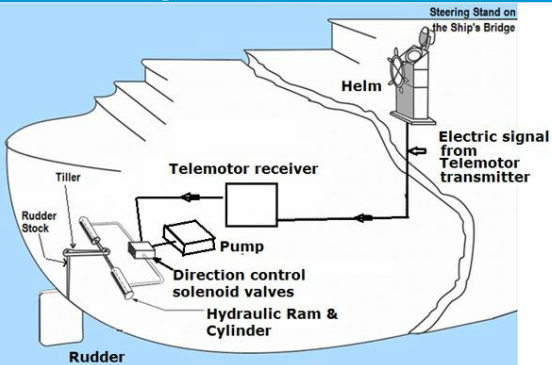

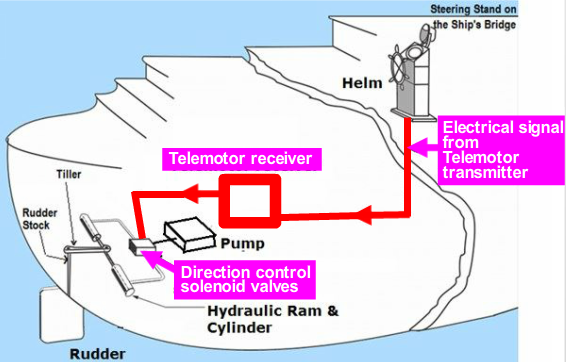

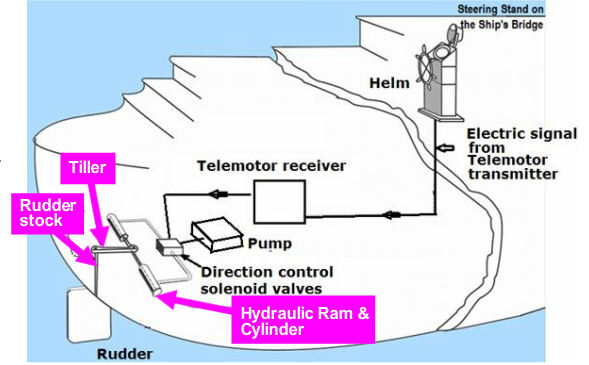

Electrohydraulic steering gear respond to rudder orders transmitted electrically from the helm in the ship’s bridge to the steering gear, located directly above the rudder in the stern.

The steering control (Telemotor transmitter) on the navigation bridge sends electrical signals to the Telemotor receiver located in the steering gear room of the ship.

In the steering gear room this Telemotor receiver sends electrical signal to Direction control solenoid valves.

These solenoid valves control the flow of oil between:

⦁ Hydraulic pump

⦁ Hydraulic Rams

There are 2 main hydraulic pumps that power the hydraulic rams. Normally at sea one pump is in use and other is on standby. They can also be run together when quicker response is required, in pilotage and coastal waters.

The hydraulic Rams are connected to the tiller which in turn is connected to the rudder stock.

The tiller converts the reciprocating movement of the hydraulic Rams to the rotary motion of the rudder stock, which in turn moves the rudder.

SOLAS Rule for Steering Gear

1. Main and Auxiliary Steering Gear (Hydraulic)

⦁ Every ship shall be provided with an efficient main steering gear and subject to sub regulation (7), an efficient auxiliary steering gear. The main steering gear and the auxiliary steering gear shall be arranged so that the failure of one of them will not render the other one inoperative.

Rudder stock and components

2.

(a) The steering gear components and the rudder stock shall be of sound and reliable construction. In particular single essential components such as tillers and hunting gear shall be designed and constructed to withstand, with an adequate factor of safety, the maximum working stresses to which they may be subjected. Any bearings for such essential components shall be of a suitable type which shall be permanently lubricated or provided with lubrication fittings.

b) The design pressure for steering gear components and piping subject to internal hydraulic pressure shall be at least 1.25 times the maximum working pressure anticipated when the steering gear is operating taking into account pulsating pressure due to dynamic loads, shall be taken into account for the design of piping and components if the certifying authority considers it appropriate.

c) Relief valves shall be fitted to any part of the hydraulic system which can be isolated and in which pressure can be generated from a power unit or from external forces. The pressure at which relief valves operate shall not exceed the design pressure. The valves shall be of adequate size so as to avoid an undue rise in pressure above the design pressure.

Steering Gears others than Hydraulic

3.Steering gears other than of the hydraulic type shall achieve equivalent standards to those required by this regulation.

Capability of main Steering gear and Rudder Stock

4.The main steering gear and rudder stock shall-

a) Be of adequate strength and sufficient to steer the ship at maximum ahead service speed,

b) Be capable of putting the rudder over from 35 degrees on one side to 35 degrees on the other side with the ship running ahead at maximum speed and, under the same conditions, from 35 degrees on either side to 30 degrees on the other side is not more than 28 seconds.

c) Be operated by power if necessary to meet the requirements of paragraph(b) and in any case when the diameter of the rudder stock in way of the tiller is required to be greater than 120 millimeters excluding additional strengthening for navigation in ice, and

d) Be designed so that they will not be damaged at maximum astern speed.

Capability of Auxiliary Steering Gear

5.The auxiliary steering gear shall-

a) Be of adequate strength and capable of being brought speedily into action in an emergency,

b) Be capable of putting the rudder over from 15 degrees on one side to 15 degrees on the other side in not more than 60 seconds with the ship at its deepest seagoing draught and running ahead at one half of the maximum ahead service speed or 07 knots, whichever is the greater, and

c) Be operated by power if necessary to meet the requirements of paragraph(b) and in any case when the diameter of the rudder stock in way of the tiller is required to be greater than 230 mm excluding additional strengthening for navigation in ice.

6. Steering gear power units

a) Main and auxiliary steering gear power units shall-

⦁ Be arranged to re-start automatically when power is restored after a power failure

(b)be capable of being brought into operation from a position on the navigation bridge, and

(c)be provided with an audible and visual alarm on the navigating bridge that will operate in the event of a power failure to any steering gear power unit.

7. Auxiliary Steering Gear need not be fitted if

a) An auxiliary steering gear need not be fitted if-

b) Two or more identical steering gear power units are fitted which when operating simultaneously are capable of operating the rudder in accordance with the requirements of subregulation (4)(B) and

c) The main steering gear is so arranged that after a single failure in its piping units the defect can be isolated so that steering gear capability can be maintained or speedily regained. A steering gear with a proven record of reliability that does not comply with this paragraph may be permitted by the certifying authority on ships the keep of which was laid before 1 september 1986.

Steering Gear control on Navigation Bridge

8.

a) Main steering gear control shall be provided on the navigating bridge and in the steering gear compartment. Two independent control systems operable from the navigating bridge shall be provided for a steering gear arranged in accordance with subregulation (7)

A single hydraulic telemotor control system may be permitted by the certifying authority on any ship other than a tanker, chemical tanker or gas carrier of 10000 tons or over. The steering wheel or steering wheel or steering lever need not be duplicated.

b) Auxiliary steering gear control shall be provided in the steering gear compartment and, if the auxiliary steering gear is power operated, from the navigating bridge. Any auxiliary steering gear control system provided on the navigating bridge shall be independent of the control system for the main steering gear.

Electrical Requirements

9.Every main and auxiliary steering gear control system shall-

a) If electric, be served by its own separate circuit supplied from a steering gear power circuit from a point within the steering gear compartment or directly from switchboard busbars supplying that steering gear power circuit at a point on the switchboard adjacent to the supply to the steering gear power circuit.

b) Be provided in the steering gear compartment with means for disconnecting the control system from the steering gear it serves,

c) Be capable of being brought into operation from a position on the navigating bridge,

d) Be provided with an audible and visual alarm on the navigating bridge that will operate in the event of a failure of the electric power supply to the control system and

e) Be provided only with short circuit protection for the electric supply circuits.

Electrical Power Circuits

10.

The electric power circuits and the steering gear control system with the associated components, cables and pipes required by this regulation and regulation 26 shall be separated as far as practicable throughout their length.

Means of Communication

11.

A means of communication shall be provided between the navigating bridge and the steering gear compartment.

Rudder Angular Position

12.The angular position of the rudder shall be indicated in the steering gear compartment and, if the main steering gear is power operated, at the steering station on the navigation bridge. The rudder angle indicator system shall be independent of any steering gear control system.

Hydraulic System

13.Hydraulic power operated steering gear shall be provided with-

a) Arrangements to maintain the cleanliness of the hydraulic fluid taking into consideration the type and design of the hydraulic system.

b) A low level alarm for each hydraulic fluid reservoir arranged to give audible and visual alarms on the navigating bridge and in the machinery space in the event of leakage of the hydraulic fluid, and

c) A fixed storage tank having sufficient capacity to recharge at least one power actuating system, including the reservoir, where the main steering gear is required to be power operated. The storage tank shall be provided with a contents gauge and shall be permanently by piping in such a manner that the hydraulic systems can be readily recharged from a position within the steering gear compartment.

Steering gear compartment access

14.

The steering gear compartment shall be readily accessible and, as far as practicable, separated from the machinery spaces. Handrails and gratings or other non-slip surfaces be provided to ensure suitable working conditions at the steering gear machinery and controls in the event of hydraulic fluid leakage.

Operating instructions and Block Diagram

15.

Simple operating instructions with a block diagram showing the changeover procedure for remote steering gear control systems and steering gear power units shall, where applicable, be permanently displayed on the navigating bridge and in the steering gear compartment.

Emergency power source

16.

An alternative power supply shall be provided in every ship where the diameter of the rudder stock is required to be 230 mm or more excluding any strengthening for navigating in ice. The alternative power supply shall be provided automatically within 45 seconds either from the emergency source of electric power or from an independent source of power located in the steering gear compartment. The independent source of power shall be used for this purpose only.

The alternative power supply shall be at least sufficient to provide power for the steering gear to comply with the performance requirements of subregulation (5)(b) and for its associated control system and rudder angle indicator. The alternative power supply shall have a capacity sufficient for at least 30 minutes of continuous operation in every ship of 10000 tons or over at least 10 minutes of continuous operation in any other ship.

Requirement for large ships

17.

a) In every tanker of 10000 tons or over and every other ship of 70000 tons or over the main steering gear shall have two or more identical power units complying with the requirements of subregulation (7) (a)

Single failure Requirements

- The main steering gear in every tanker of 10000 tons or over shall , subject to the requirements of sunbregulations (19) and (20), be so arranged that in the event of loss of steering capability due to a single failure in any part of one of the power actuating systems, other than seizure of a rudder actuator, steering capability shall be regained in not more than 45 seconds after the loss of one power actuating system. The main steering gear shall comprise either:- (a) 2 independent and separate power actuating systems each capable of meeting the requirements of sub regulation (4)(b) or (b) At least 2 individual power actuating systems which shall be capable of meeting the requirements of subregulation (4)(b) when acting simultaneously in normal operation. Interconnection of the hydraulic power actuating systems shall be provided, if necessary for compliance with this requirement. The loss of hydraulic fluid from one system shall be capable of being detected and the defective system automatically isolated so that the other actuating system or systems remain fully operational.

Single failure criteria relaxation

19. In any tanker of 10000 tons or over but of less than 100000 tonnes deadweight the main steering gear may be constructed in such a way that the single failure criterion required by sub regulation (18) is not applied to the rudder actuator or actuators provided that-

(a) Steering capability shall be regained within 45 seconds of a single failure of any part of the piping system or in one of the power units and

(b) the design, construction and testing of the rudder actuator is in accordance with the requirements of schedule 2 if only one actuator is provided.

Modes of Operation

Maneuvering

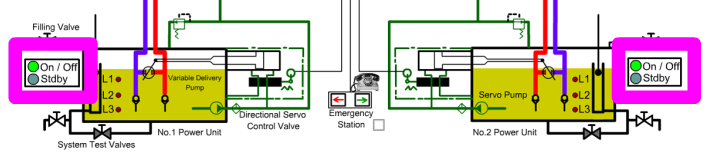

At arrival or departure from the berth, or navigating in congested waters, both the steering gear power units are operated.

Normal Operation

When the vessel is under way, one power unit is in operation while other is on standby.

The power units are changed over after every 24 hours of operation.

Single Failure

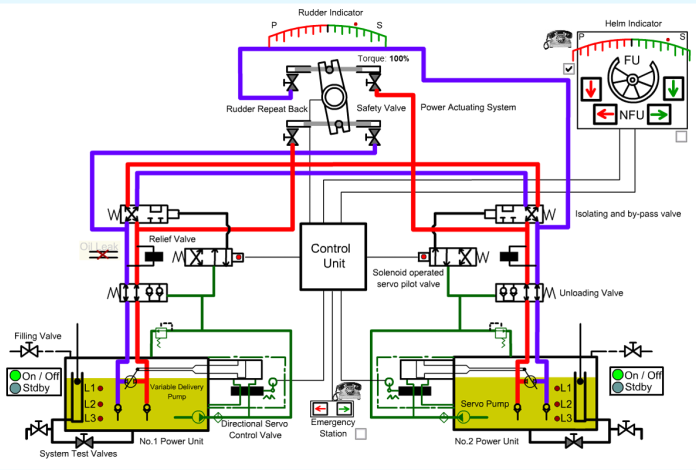

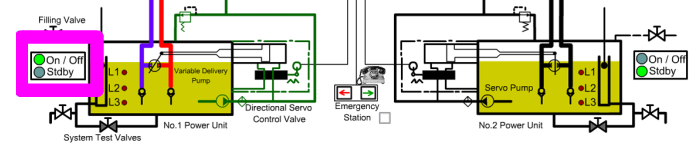

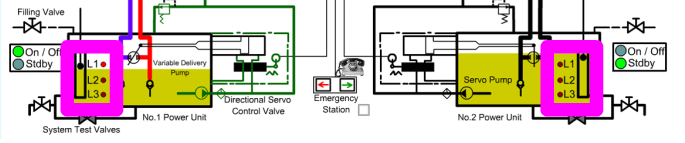

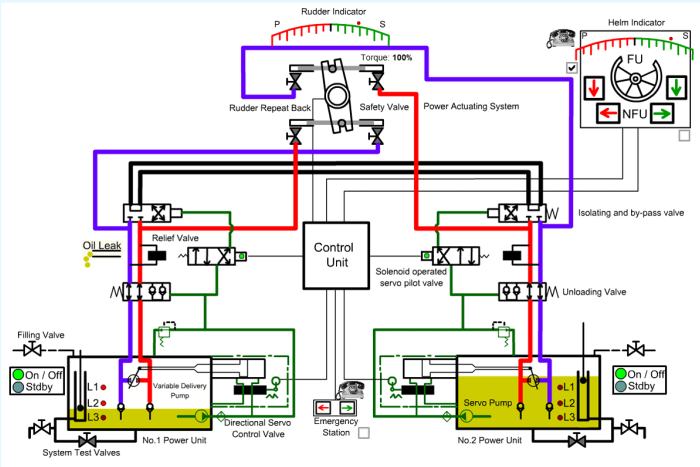

Two main power and servo power units draw from a two compartment tank fitted with oil level switches arranged at three levels.

L1 gives an initial alarm following loss of oil from either system.

In normal operation one or both power units provide hydraulic power to all four rams.

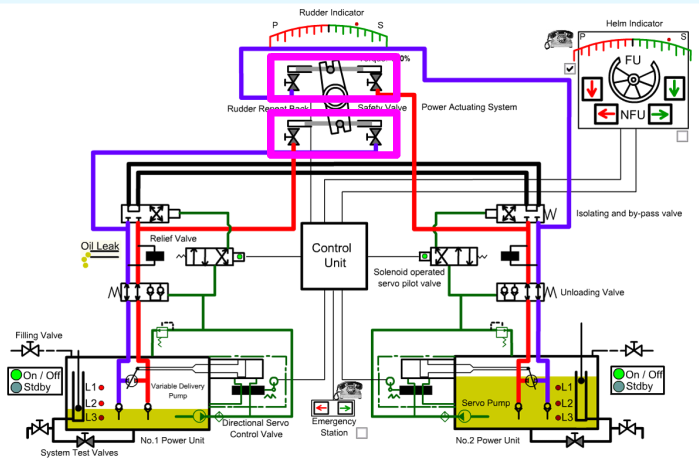

Continues loss of oil initiates one or both of the L2 switches.

These energize their respective solenoid operated servo valves, causing the combined isolating and bypass valves to operate, splitting the system such that each power unit supplies two rams only.

At the same time if one power unit is stopped it is automatically started if it is on standby.

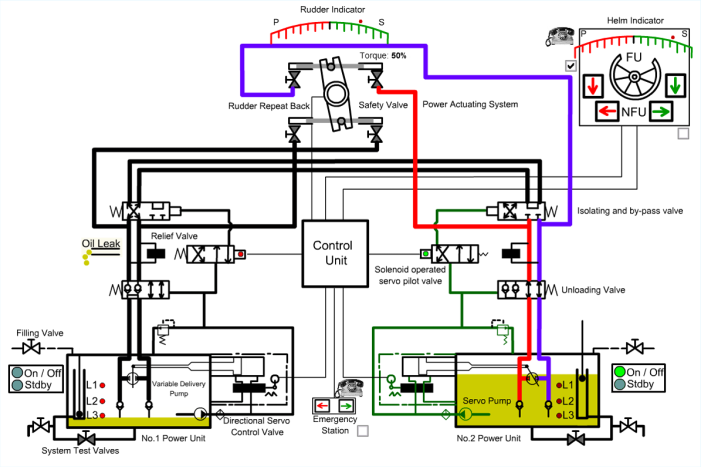

Further loss of oil, and the system on which it is occurring will operate one of the L3 switches.

This will close down the power units on the faulty side. Steering then continues, uninterrupted but at half the designed maximum torque on the sound system.

The defective system is out of action and isolated.