Gas Equipment

The Catalytic Filament Combustible Gas (CFCG) Indicator is used for measuring hydrocarbon gas in air at concentrations below the lower flammable limit (LFL). The scale is graduated in % LFL. A CFCG Indicator must not be used for measuring hydrocarbon gas in inert atmospheres.

Two types of instrument are available commercially for measuring hydrocarbon gas concentrations in excess of the LFL or in oxygen deficient (inerted) atmospheres ‐ the Non‐ Catalytic Heated Filament Gas Indicator and the Refractive Index Meter. The scale is graduated in % volume hydrocarbon gas.

Operating Principle of Explosimeter:

The sensing element of a CFCG indicator is usually a catalytic metal filament heated by an electric current. When a mixture of hydrocarbon gas with air is drawn over the filament; the gas oxidises on the hot filament and makes it hotter. This increases its resistance and the change of resistance provides a measure of the concentration of hydrocarbon gas in the mixture.

This oxidation can only take place if there is sufficient oxygen present.

The non‐catalytic filament is not affected by gas concentrations in excess of its working scale. The instrument reading goes off the scale and remains in this position as long as the filament is exposed to the rich gas mixture.

Calibration:

The calibration is carried out using a Span gas of known hydrocarbon‐air mixture. The calibration to be carried out as per manufacturer’s instructions.

Operating Principle of Tank Scope:

The sensing element of this instrument is a non‐catalytic hot filament. The composition of the surrounding gas determines the rate of loss of heat from the filament, and hence its temperature and resistance.

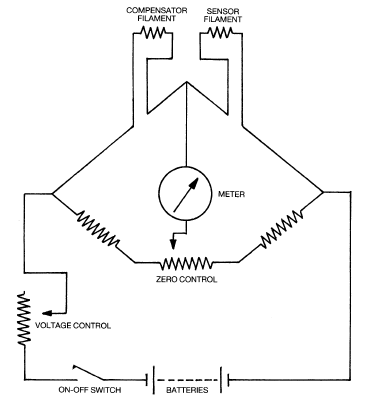

The sensor filament forms one arm of a Wheatstone bridge. The initial zeroing operations balance the bridge and establish the correct voltage across the filament, thus ensuring the correct operating temperature. During zeroing the sensor filament is purged with air or inert gas that is free from hydrocarbons.

The presence of hydrocarbon changes the resistance of the sensor filament and this is shown by a deflection on the bridge meter. The rate of heat loss from the filament is a non‐linear function of hydrocarbon concentration and the meter scale reflects this non‐linearity. The meter gives a direct reading of % volume hydrocarbons.

Calibration:

The calibration is carried out using a Span gas of known hydrocarbon‐nitrogen or inert gas mixture.

The calibration to be carried out as per manufacturer’s instructions.