Explain the procedure for taking over watch in manned engine room Taking over a Watch:

- Check the funnel emissions. White smoke, black smoke, steam or sparks.

- Check steering gear & fridge flats.

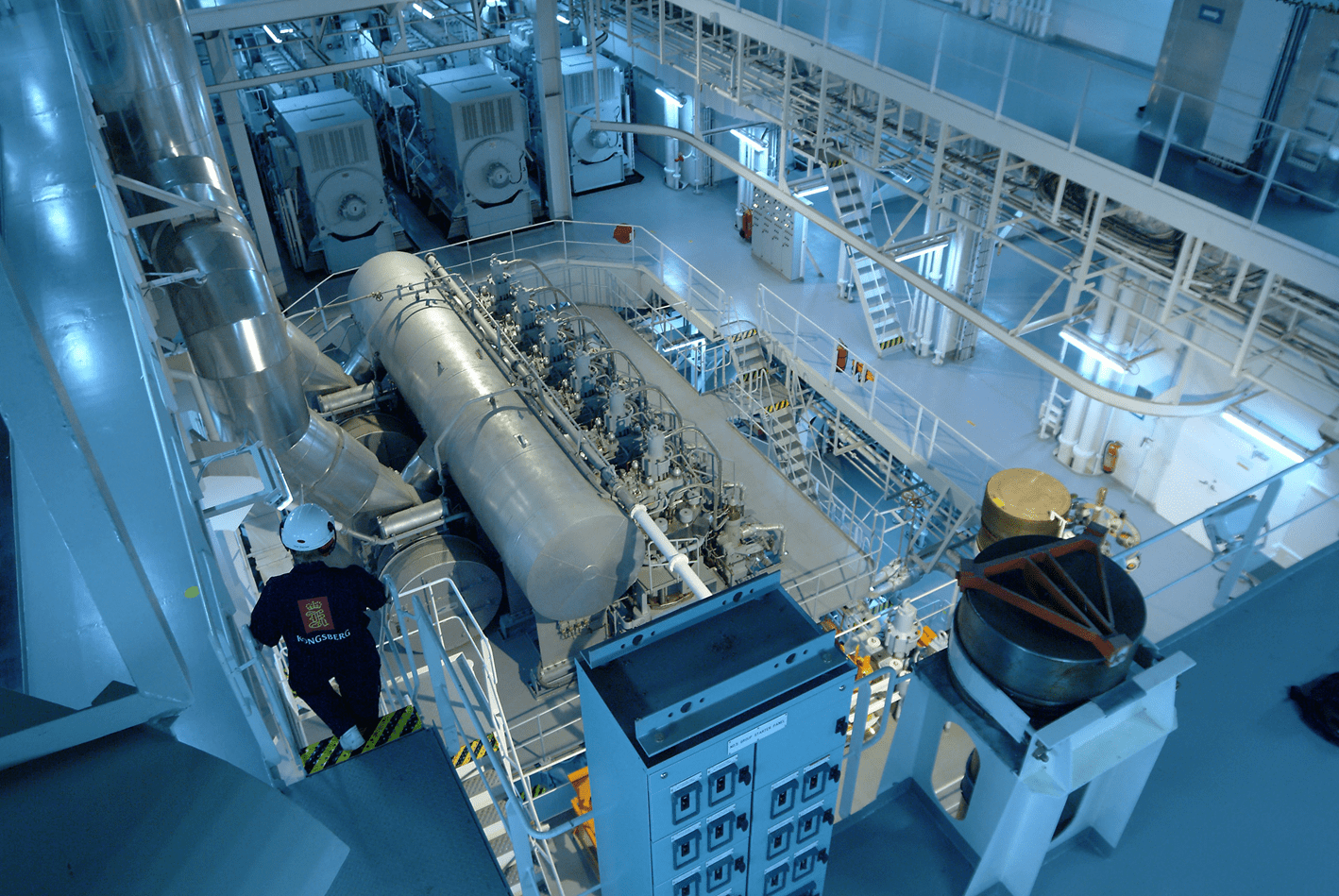

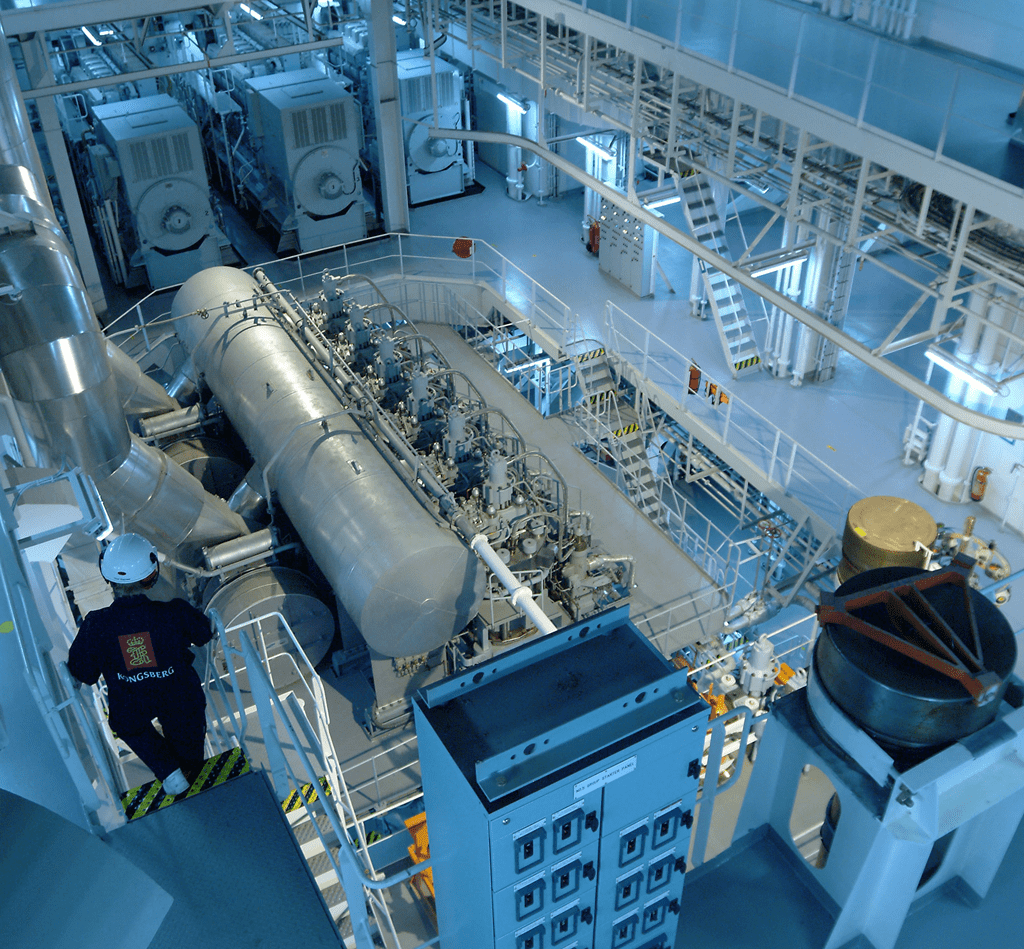

- Enter the engine room from the top. Do not use the lift.

- Check cooling water header tank.

- Check main engine cooling water returns & temperatures.

- Check piston cooling water returns & temperatures.

- Listen for any unusual noises.

- Check turbocharger oil levels

- Check observation tank for signs of oil.

- Check mist detector.

- Check condition of bilges.

- Check purifier flat and condition of the fuel oil tanks. i.e. full, empty temperature Drain of water.

- Enter control room. check logbook and note any irregularities.

- Confirm the condition of the electrical supply equipment. How many alternators on load, amount of load on the board, Earth faults, Stand by machines?

- Read any current standing orders.

- The duty engineer should then inform the engineer taking over the watch of any abnormal operating conditions which have occurred during the watch.

- Any orders from the Bridge. Recorded in the logbook should be pointed out.

- Any repairs should be reported together with information on any machinery that has been dismantled.

Ten important things that you will do / check when on a watch in the engine room. List the indicators and alarms provided with bridge control of M/E.

E/R Watch Keeping:

- All log readings should be verified with actuals at the start of watch

- Verify if there are any special order or instructions.

- Evaluate the work in progress and its effect on safety etc.

- Confirm levels of tanks for fuel, water, slop, ballast etc. Also note bilge levels.

- Operating mode of all equipment and standby for each.

- At appropriate intervals, inspection should be made of main, auxiliary and steering equipment along with all liquid levels including those mentioned above.

- Bridge orders must be promptly carried out and recorded, special requirements if any of the bridge should be carried while keeping the chief engineer well informed.

- Duties like transfer of fuel etc. should be carried out carefully as it will need almost continuous attention.

- During the watch, a log or record of various parameters will have to either be taken manually or will be provided automatically.

- All values should be within normal range.

- Through logbook, consumption of lubricating oil, fuel oil, fresh water and also generation of fresh water during the watch will be known and should be within normal values.

- Where situations occur in the machinery space which may affect the speed, manoeuvrability, power supply or other essentials for the safe operation of the ship, the bridge should be informed as soon as possible.

Indicators and Alarms on Bridge:

Bridge instrumentation will vary but usually includes

- the tachometer or engine rpm indicator,

- Direction of rotation indicator

- Air starting pressure gauge.

- Emergency Stop for main propulsion engine (For UMS)

- Alarm panel indicating any machinery fault during UMS.

- Emergency overriding of parameter like high temperature of thrust bearing.

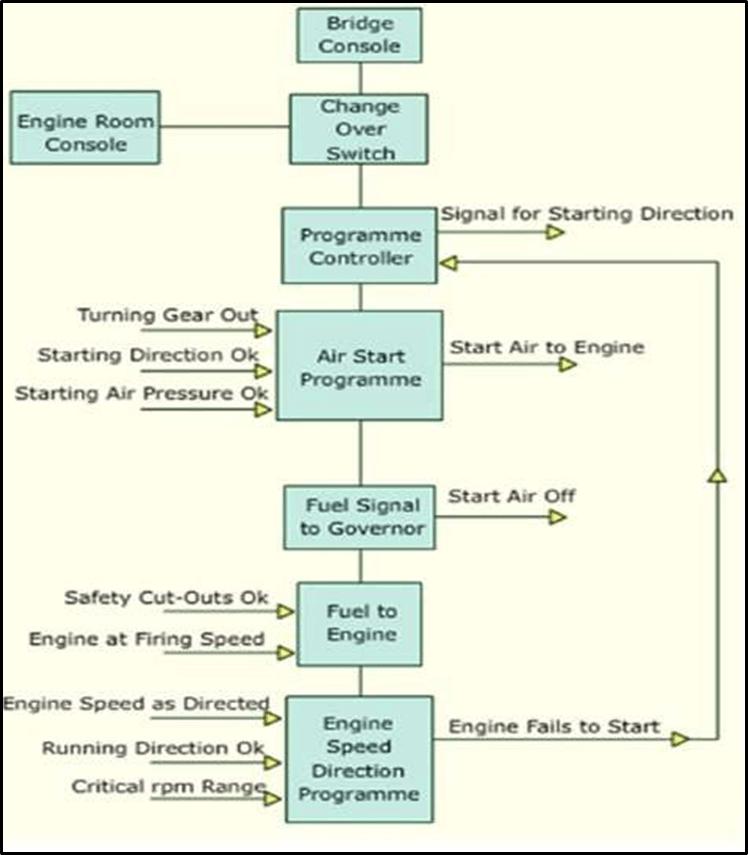

Flow diagram the sequence of operations while starting a direct coupled diesel engine remotely

Bridge control of Main Engine:

- Starting and stopping, reversing of engine or propeller pitch and speed control are possible from the bridge.

- An emergency direct arrangement for stopping the engine is provided in the bridge, independent of the normal bridge control system.

- If the direction for the engine on air is set as required, the Turning Gear (TG) is disengaged, and the starting air pressure sufficient, air will admit to the chosen cylinders to start the engine.

- At firing speed a signal will be sent to the governor for fuel release.

- Provided the essential parameters, such as lubricating oil pressure, cooling water pressure, air spring pressure, etc, are correct and the respective cut-outs do not block the fuel supply, fuel will be injected and the engine will start to run in the required direction.

- A further program checks the running direction, and speed, and adjusts the signal to the governor for regulating the speed according to the telegraph order.

- The program also ensures that continuous running at critical speed range (if any) is avoided, by a large increase or reduction in fuel charge in quickly passing over the critical range.

- In case the engine fails to start, the program is repeated up to 3 times, after which the system gets locked and an alarm is sounded for manual intervention.

SOLAS requirements on bridge control systems

- Means of preventing overload of propulsion machinery.

- System shall be provided with an emergency stopping device on the navigation bridge.

- It shall be independent of the navigation bridge control system.

- Order from the bridge shall be also indicated at engine control system.

- Remote operation of propulsion system shall be possible only from one location at a time.

- Each location shall have indicators showing which location is in control.

- While transferring control, there shall not be significant change in propeller thrust, and means to confirm this is to be provided.

- Control of propulsion machinery from local position in even of failure of automation or remote-control system, should be possible.

- In case of remote automatic control system failure, an alarm should be given off.

- Control now should be possible from the local control station.

Precautions to be taken in Engine Room for rough weather

- Levels of hydraulic oil for steering gear should be kept well about the minimum to avoid problems because of heavy pitching and rolling of the ship.

- Propeller would come out of water during heavy weather and this will cause load fluctuation on the main engine. Thus, RPM of the propeller must be reduced to safe values.

- Appropriate levels at LO tanks, LO sumps, FO tanks and other tanks shall be maintained. Varying levels during rolling and pitching might lead to low pressure or pump loosing suction. This may actuate shut down of propulsion plant.

- Keep standby power generating unit on.

- There should be no loose items.

- All spares and tools including spare LO drums and other machinery parts including those on the deck should be properly secured, well in advance of expected rough weather.

- All drip trays save all’s etc. should be kept well drained and should have no accumulated liquids which may spill due to heavy rolling and pitching of the ship.

Things to check / do on 2 hrs notice to arrival port in E/R

- The bridge will start reducing the speed to manoeuvring speed.

- Start additional Aux. generator in parallel.

- Stop the steam turbine and shaft generator if fitted.

- Ensure the power is available for deck machinery and bow thruster.

- The bridge will also start additional steering gear unit.

- Take a round of steering gear room and check oil level linkages and motor current.

- Start the boiler and raise the pressure, if exhaust gas boiler was running previously.

- Close the dampers for exhaust gas boiler and open bypass.

- Stop the freshwater generator.

- Shut and lock sewage direct overboard discharge and start sewage plant or open valve for sewage holding tank.

- Close the sea chest valve of the side of the ship which is going to face the berth.

- Change over to high sea suction from low sea suction.

- Drain the air receivers.

- The engine is tested for ahead and astern direction from bridge.

- The steering gear is also tested for full rudder angle.

- Blow through indicator cocks to check they are clear

- When manoeuvring ends, sea passage flow meter counter is taken for calculation of oil consumption from full away to end of sea passage.

Procedure in engine room on two hours’ notice for departure port

- Inform chief engineer officer whenever notices for ME on standby received.

- Test controls and synchronise engine room clock.

- Try out communication system.

- Preparation of Bow/Side Thruster as applicable.

- Auxiliary boilers to be kept on warm up when preparing for departure from port.

- Start all associated machinery required for ME operation.

- Main air distributor valve and control air valve to main engine to be kept open.

- Start boiler water circulating pump for departure from port.

- Press up air receivers and blow off any moisture from the system

- Start main engine lube oil pump, fuel oil booster pump and main cooling sea water pump.

- Throttle/bypass the coolers for lube oil and cooling water systems.

- Adjust stern tube lube oil level according to ballast/loaded passage.

- A quick round of engine room.

- Check oil level, header tank level, cylinder oil daily tank level.

- Check the pressure of fuel oil pump, booster pump, lube oil pump ettc…Check sump oil level in air compressor.

- Drain air bottles for any water inside.

- Check that the turning gear is out.

- Check parameters of running machinery.

- Start additional generator to supply for additional demand of power from winches and thrusters.

- Start exhausts gas boiler water circulating pump.

- Check the telegraph for functioning in conjunction with deck officer on watch.

- Telegraph is checked for local and remote panel.

- Try out steering gear as per SOLAS.

- Check the functioning of limit switches in steering gear.

- Check gyro reading in steering gear and cross check with reading on the bridge.

Unmanned machinery spaces? Describe the arrangements necessary for effective engineering watches to be maintained for the purpose of safety during UMS operation

Unmanned Machinery Space:

- UMS or Unattended / Unmanned Machinery Spaces is a marine automation system for ship’s engine room.

- Unlike conventional watch system on normal cargo ships, in UMS class vessels, there are usually no engineer officers on watch in the engine room (from 1700 hrs. to 0700 hrs).

- If there is a malfunction in any machinery, an alarm will be sounded in the engine room as well as in the ‘on duty’ engineer’s cabin.

- It’s then the engineer’s duty to go down in the engine room and investigate the alarm.

As per Solas Chapter II – 1:

Fire Precautions:

- Means to detect and provide alarms for boilers and scavenge air belts.

- Oil mist detector and engine bearing temperature monitor must be fitted.

Protection against Flooding:

- Automatically operated bilge pumps.

- Sea inlet valves and emergency bilge suction shall be made to operate when space is flooded.

Bridge Controls:

- the tachometer or engine rpm indicator,

- Direction of rotation indicator

- Air starting pressure gauge.

- Emergency Stop for main propulsion engine (For UMS)Alarm panel indicating any machinery fault during UMS.

Alarms system:

- Alarms shall sound in ECR, bridge and engineer’s accommodation.

- Alarms system must be provided with continuous power supply. In case of power failure, automatic change over to stand by power supply shall take place.

- Alarms shall continue until they are accepted, and the visual indications of individual alarms shall remain until fault has been rectified.

- Alarms shall be provided for all important pressure, temperatures and fluid levels.

- A centralized control position shall be arranged with the necessary alarm panels and instrumentation indicating any alarms

Safety System:

- Alarm followed by auto shut down of machinery and boiler operations in case of serious malfunction posing immediate danger.

- Shutdown of main propulsion unit shall not take automatically unless the malfunction can lead to complete breakdown or explosion.

Conditions that determine composition of E/R watch. What are the responsibilities of a watch keeping engineer and explain watch keeping routines in E/R?

When deciding the composition of the engineering watch, which may include appropriately qualified ratings, the following criteria shall be considered:

- The type of ship and the type and condition of the machinery;

- The adequate supervision, at all times, of machinery affecting the safe operation of the ship; .

- Any special modes of operation dictated by conditions such as weather, ice, contaminated water, shallow water, emergency conditions, pollution abatement;

- The qualifications and experience of the engineering watch;

- The safety of life, ship, cargo and port, and protection of the environment;

- The observance of international, national and local regulations; and

- Maintaining the normal operations of the ship.

Responsibilities of a Watch Keeping Engineer:

- Duty engineer shall give the watchkeeping personnel all appropriate instructions and information required for keeping of the watch.

- When ER is manned, duty engineer shall be readily capable of operating propulsion equipment in response to needs for changes in direction or speed.

- During UMS duty engineer shall be immediately available and on call to attend the machinery spaces.

- All bridge orders shall be promptly executed.

- Changes in direction or speed of the main propulsion units shall be recorded.

- Main propulsion unit controls, when in the manual mode of operation, shall be continuously attended during stand-by or manoeuvring conditions.

- When engine room is put in a stand-by condition, always prepare machineries and sufficient power to be made available.

- They shall keep the main propulsion plant and auxiliary systems under constant supervision until properly relieved and shall periodically inspect the machinery in their charge.

- D/E shall be fully aware of all preventive maintenance, damage control or repair operations to be performed during his watch.

- Any machinery not functioning properly, expected to malfunction or requiring special service shall be noted along with any action already taken.

- D/E shall not leave machinery spaces unsupervised in a manner that would prevent the manual operation of E/R plant.

Checks are made before unmanning The Engine room? What is safe procedure for entry in case of alarm in unmanned condition?

- All FO/LO and freshwater tanks/sumps are adequately filled

- Bilges are dry and high-level alarms are operational

- Make sure sludge and bilge tanks are minimum safe level

- Smoke and Fire alarms are operational, and no zone/detector is isolated

- All alarms and safety cut-outs are operational

- Compressed air receivers are fully charged, and one main air receiver is isolated

- FO/DO overflow tanks are empty or at unpumpable ROB

- All soundings self-closing cocks are in closed position and sounding caps are closed.

- Stopped diesel generators are on standby

- All standby pumps and machinery system are on standby and auto start.

- All ventilation fans are running

- Electric kettle plugs are removed in ECR

- Loose items are secured

- Workshop welding plug is removed

- Acetylene and Oxygen cylinder line valves are closed

- Main Engine is on bridge control

- Control is transferred to bridge and duty officer is informed about time of commencement of UMS

Safe Procedure for entry in E/R during UMS Alarm:

- Inform duty officer on bridge prior entering the engine room.

- Activate dead man’s alarm as soon as entering ER.

- Inspect the alarm and take appropriate action.

- Keep resetting dead man’s alarm.

- Once the job is done, switch off dead man’s alarm.

- Inform duty officer on the bridge.

Dead Man’s Alarm:

- The dead man alarm system provides a safeguard for the duty engineer who enters the machinery space during periods of UMS operation in response to an alarm or for any other reason.

- Should that engineer get into difficulty whilst alone in the machinery space, the dead man alarm system provides an indication to others that the engineer is in the machinery space but unable to respond.

How a two-stroke main engine is prepared for Manoeuvring after 3 days stay in Port?

24 hrs prior departure:

- Verify stock of F.O/LO/stores/chemicals/spares etc for adequacy

- Verify settling / service tank levels of HFO/DO and LO sump

- Start flashing Boiler if required, open heating steam for oil tanks, maintain temperature and drain water

- Ensure oil filters clean and stand by filters ready for c/o if required

- Check alarms and safety systems

- Check soundings of all tanks in E/R including cofferdams and record

- Check stern tube oil tank level and condition of oil in stern tube by draining a small quantity

12 hrs prior departure

- Do the steering gear checks and trials as per SOLAS

- Fill up air bottles and drain condensate

- Turn engine on turning gear and check oil flow through bearings (prop clearance to obtain) and disengage turning gear.

- Circulate jacket cooling water through heater and engine if required in cold climate

- Record all activities in logbook

On receipt of 2 hrs notice:

- Take an additional generator on load and Start required propulsion plant machinery

- Obtain prop clearance, blow through and try out engine on both ahead and astern

- Inform Bridge readiness