Reverse Osmosis System of Fresh water generation on board

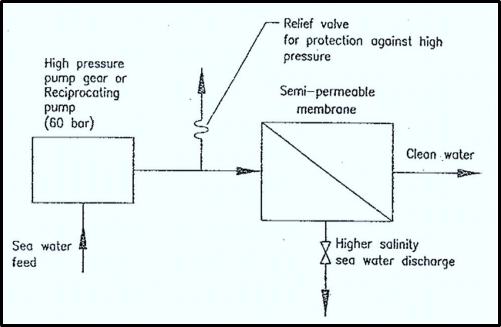

- Reverse osmosis is a water filtration process which makes use of semi-membrane materials.

- Salt water on one side of the membrane is pressurised by a pump and forced against the material.Pure water passes through but not the salts.

- Pressure required to force the pure water through is called osmotic pressure and requirement of osmotic pressure is higher if salinity of the salt water is higher.

Working:

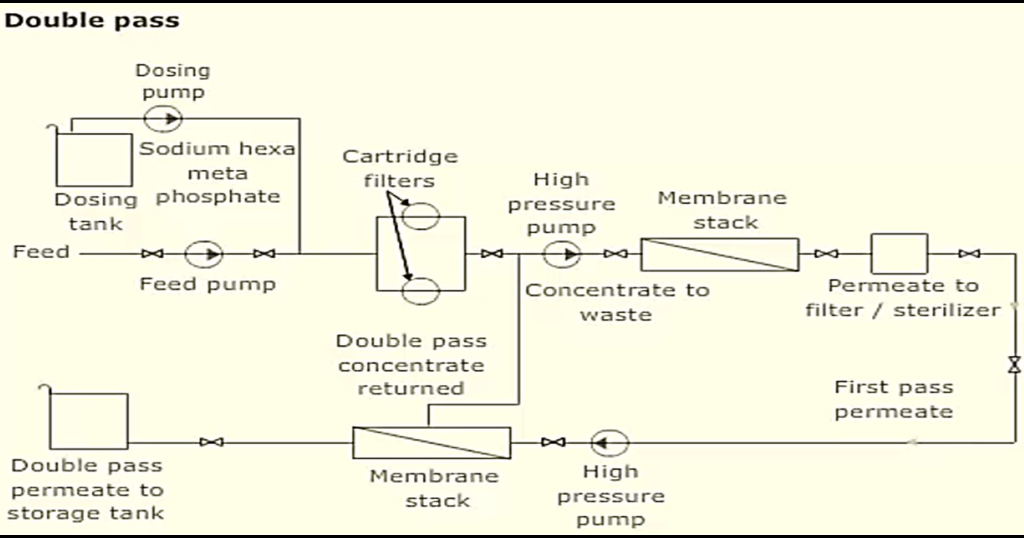

- Sea water is supplied to cartridge filters by low pressure booster or feed pump.

- Pre-treatment of water is done using chemical dosing system before it comes in contact with membrane.

- After the filters, the flow passes through high pressure system and to the membrane stack.

- The filtered water is also called permeate. This permeate then acts as a feed for second pass.

- The permeate again passed through another membrane stack.

- The second pass permeate will have very low Total Dissolved Solids (TDS) content.

- It is also used to dilute seawater before entering the first pass.

- The salt concentrate is drained out from the membrane stack.

- The filtered water is sterilized and pumped to the storage tank.

Osmotic pressure & briefly explain why pressure osmosis applied in RO system is very high

- In reverse osmosis water filtration process, salt water on one side of the semi-membrane material is pressurised by a pump and forced against the material.

- Pure water passes through but not the salts.

- Pressure required to force the pure water through, is called osmotic material pressure.

- More the salinity of the water, higher osmotic pressure is required to force the water through the membrane.

- A steady feed of sea water must be supplied, so that salinity is steady and the osmotic pressure required is also steady.

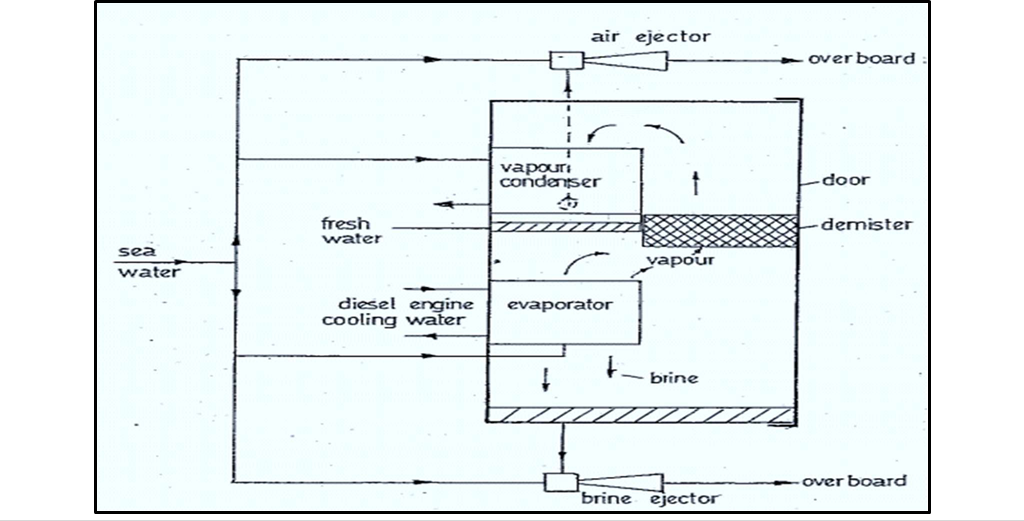

Low-pressure evaporator. How waste heat from main engine is used for producing fresh water on board the ship?

- The sea water is boiled using energy from a heating coil.

- By reducing the pressure in the evaporator shell, boiling can take place at about 40 to 60°C.

Working:

- Heat from diesel engine cooling water is used to evaporate a small fraction of the sea water feed in the plate type evaporator.

- Unevaporated water is discharged as brine by brine ejector.

- Evaporated water passes through the demister to the plate type vapour condenser.

- After condensation in the condenser, it is discharged to fresh water storage tank by fresh water (distillate) pump.

- During entire operation the feed rate to evaporator is fixed by orifice plate.

- In the event of salinity of fresh water density exceeding a pre-determined value (usually 10ppm) the solenoid- controlled dump valve divers the flow to the bilge preventing contamination of the water.

- Air ejector continuously ejects any gases which were not condensed.

- This way the shell is maintained at high vacuum, a must requirement to boil water at low temperatures.

Description a domestic fresh water generator used on board a ship. Various methods employed to make this water potable. Why is water passed through a carbon filter

- Fresh water produced by a fresh water generator needs to be treated in order to be able to make potable.

- Fresh water produced may contain harmful bacteria and marine organisms.

- May be acidic in condition due to the presence of CO2.Thus, initially water is passed through a device that absorbs the carbon dioxide, thus neutralising it.

- The bacteria are treated by sterilizing with chlorine.

Chlorine Sterilisation:

- Chlorine injection may be sodium hypochlorite in liquid form or calcium chloride granules.

- The chlorine content may be up to 0.2ppm for it be effective.

- The water is then passed through carbon filter in order to remove the taste of chlorine.

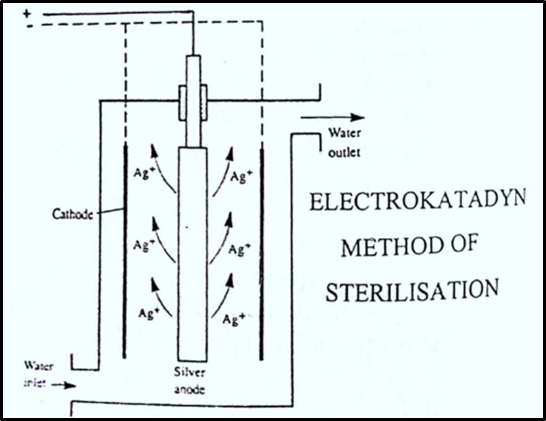

Treatment with the Electrokatadyn process:

- In this method silver ions are injected into the distillate.

- Silver anodes are used to inject silver ions and it is controlled by current. Up to 0.08 ppm of silver ions may be injected in order it to be effective.

- Silver is toxic to bacteria and does not evaporate like chlorine.

Ultra-violet Light

- When using chlorine or silver ions, the taste of the water changes and it has to be treated again through carbon filter to remove order.

- UV light from lamps can used to sterilize the water without changing any physical or chemical properties of the water.

- Short wave radiation destroys bacteria, viruses and other harmful organisms in the water

- High intensity ultra-violet sterilization lamps and pure quartz lamp tube are used in this system.

- They are connected at the discharge side of the potable FW storage tank.

Carbon Filter:

- The water is sterilised by an excess dose of chlorine provided by hypochlorite tablets.

- It is then dechlorinated in a bed of activated carbon to remove the excess chlorine.

- Any colour, taste and odour which was present in the water will also be removed by carbon.

Purposes of the following in the system

- Neutraliser unit.

- Hypo Chlorinator unit

- Sand bed filter unit

- Carbon filter bed unit

Neutraliser Unit:

- After fresh water is generated it passes through the neutraliser unit.

- Here it is treated with carbonates of calcium and magnesium.

- These carbonates are used in as the filter bed in the neutraliser.

Hypo-Chlorinator unit:

- After neutraliser, the distilled water passes through the hypo-chlorinator unit for disinfection.

- The chlorinator contains powders of hyper chloride or calcium chloride.

- The chlorine kills the bacteria present in the water.

Sand Bed Filter Unit:

- After chlorinator, the distilled water passes through the sand bed filter unit to produce clean water.

- The purpose of a sand bed filter in a fresh water generator on ships is to remove suspended solids and impurities from the seawater

Carbon Filter Bed Unit:

- The water is sterilised by an excess dose of chlorine provided by hypochlorite tablets.

- It is then dechlorinated in a bed of activated carbon to remove the excess chlorine.

- Any colour, taste and odour which was present in the water will also be removed by carbon.

Advantages of RO plant and low-pressure distillation plant

Advantages of RO Plants:

- High Water Quality: RO plants produce high-quality fresh water by removing impurities, salts, and contaminants from seawater, making it suitable for various shipboard uses.

- Compact Size: RO plants are compact in size, allowing for space-efficient installation on board ships, especially in cases where space is limited.

- Modular Design: RO plants often feature a modular design, enabling easy scalability and customization based on the ship’s water demand and available space.

- Reduced Chemical Usage: RO plants require minimal chemical additives for water treatment compared to other desalination methods, reducing chemical usage and associated costs.

- Compatibility with Automation: RO plants can be integrated into the ship’s automation systems, enabling remote monitoring, control, and efficient operation.

Advantages of Low-Pressure Distillation (LPD) Plants:

- Energy Efficiency: LPD plants operate at lower temperatures and pressures, consuming less energy compared to high-pressure distillation systems.

- Reliable and Proven Technology: LPD plants have been used on ships for many years and have a well-established track record of reliability and performance.

- Robust Design: LPD plants are known for their robust construction and ability to handle varying seawater qualities, making them suitable for a wide range of operating conditions.

- Continuous Operation: LPD plants can provide a continuous supply of fresh water, ensuring a reliable source of potable water for the ship’s crew and other onboard needs.

- Minimal Pre-Treatment: LPD plants typically require less pre-treatment of seawater compared to other desalination methods, simplifying the water treatment process.

- Easy Maintenance: LPD plants are relatively straightforward to maintain, with fewer mechanical components and simpler maintenance requirements compared to other desalination technologies

Factors affecting the production of fresh water

RO System:

- Higher salinity requires more energy and pressure to overcome osmotic forces during desalination, leading to reduced production rates and increased energy consumption.

- Feedwater temperature affects the viscosity of seawater.

- Lower temperatures increase the water’s viscosity, which can result in higher energy requirements for pumping and reduced overall fresh water production.

- Higher feedwater pressure allows for more efficient reverse osmosis.

- Fouling occurs when suspended solids, microorganisms, or mineral scales accumulate on the RO membrane’s surface, reducing water flow and freshwater production.

- Adequate pressure is needed to force water molecules through the RO membrane and separate the salt and impurities from the fresh water.

- The age and condition of the RO membranes can affect their efficiency.

- Over time, membranes may become less effective in rejecting salt and impurities, leading to reduced fresh water production.

Low Pressure Distillation System:

- Higher salinity levels require more energy to vaporize the water, leading to lower freshwater production rates.

- Higher feedwater temperatures generally lead to increased production rates as less energy is needed to heat the water to its boiling point.

- Low-pressure distillation systems can use waste heat from the ship’s engines or other onboard processes,exhaust gases, or dedicated heating systems.

- The availability and efficiency of the heat source impact the system’s overall performance.

- Scaling occurs when minerals and salts in the feedwater precipitate as the water is heated, leading to the accumulation of deposits on the heat transfer surfaces.

- Fouling can also occur due to the presence of organic matter and impurities.

- Scaling and fouling reduce heat transfer efficiency, increase energy consumption, and decrease freshwater production. Regular maintenance and proper water treatment are essential to minimize these issues.

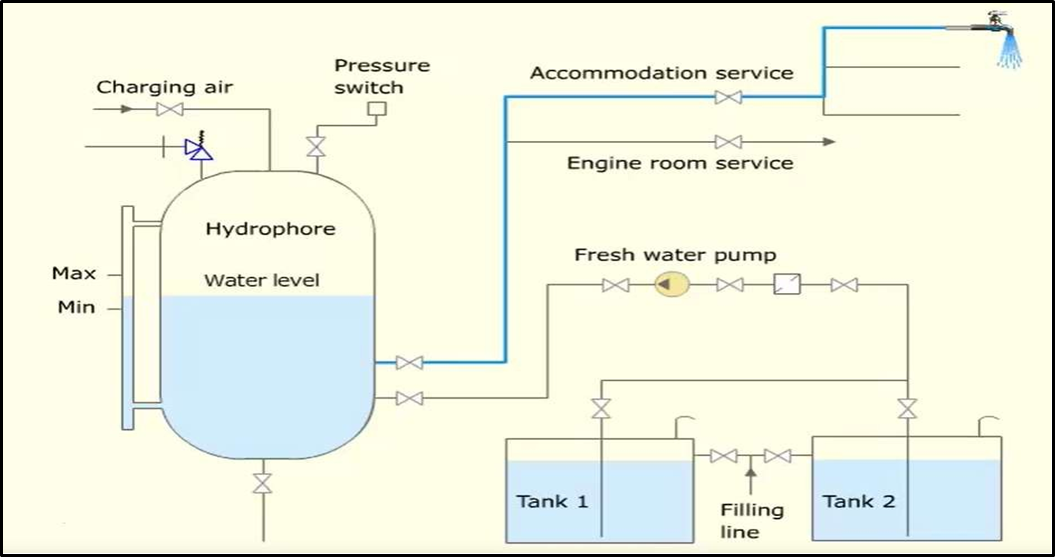

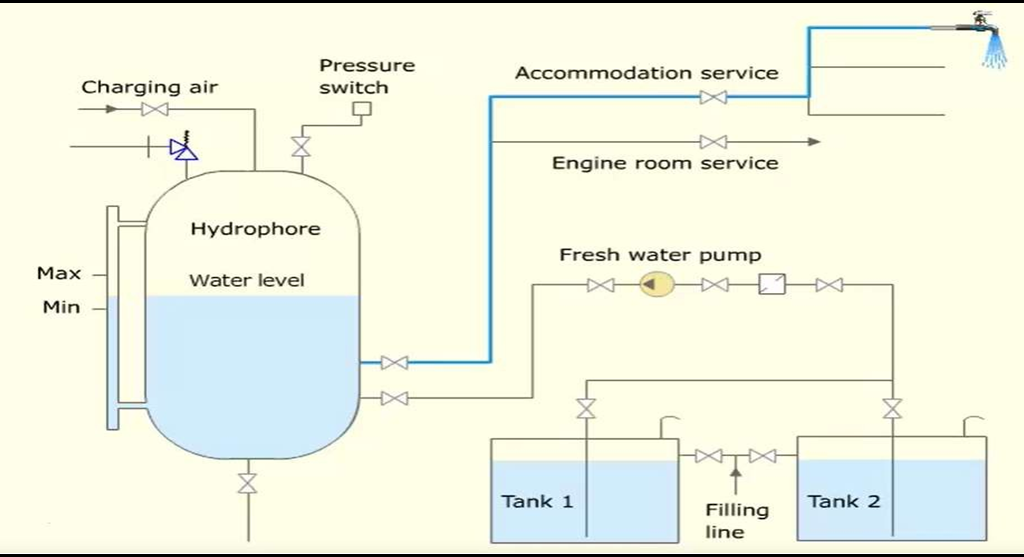

Fresh water hydrophore system

Working:

- A hydrophore system is used to maintain a constant pressure in the lines supplying water to various parts of the ship.

- Consider a fresh water hydrophore system maintained at a pressure of 4.5 Kg/cm2.In the hydrophore, water is kept pressurized by a column of compressed air.

- Initially the hydrophore is filled with water up to level slightly above the half the volume.

- Now the air charged, till the hydrophore pressure reaches 4.5 Kg/cm2.The fresh water pump in the system is set to cut in at 3.5 Kg/cm2 and cut-out at 4.5 Kg/cm2.If fresh water is consumed in any of the taps, water level and pressure in the hydrophore drop.

- As water is consumed, the tank pressure drops to 3.5 Kg/cm2.The fresh water pump now starts and supplies water from storage tank to the hydrophore, till the tank pressure reaches to 4.5 Kg/cm2.

- Thus, uninterrupted pressurized water is supplied.

State (i) Pre-treatment used with RO equipment & (ii) The Post-treatment necessary

Pre-treatment:

- Sea water is supplied to cartridge filters by low pressure booster or feed pump.

- Pre-treatment of water is done using chemical dosing system before it comes in contact with membrane in the RO system.

- The chemical sodium hexametaphosphate is added to assist the wash through of salt deposit on the surface of the elements and the sea water is sterilized to remove bacteria which would otherwise become resident in the filter.

- The water then is passed through a 10 microns absolute rated cartridge filter

- This ensures that the feed water to the RO membrane elements is free from any fine particulate matter ensuring maximum performance from the RO membrane elements.

Post Treatment:

- Post treatment is required in low-pressure fresh water generators.

- The produced water is heated to sterilisation temperature of about 80°C.Sterilise the water by chlorinating it i.e. by adding Sodium hypochlorite – 1ppm.UV rays also can be used to sterilise the water. UV rays are used in conjunction with other methods.

- Ozone is also used to sterilise the water as it is an effective oxidant. However, equipment is costly and has high running cost.

- It is important to note that if the vessel is within coastal limits, this seawater may contain harmful effluents from industrial zones and none of the sterilisation methods will give protection.