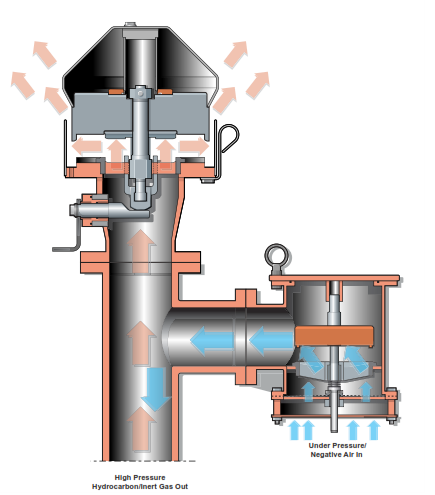

Combined pressure/vacuum valves are fitted to each cargo tank. These valves are designed to relieve positive or negative pressure in the tanks.

Combined PV valves are fitted to each cargo oil and slop tank based on the vapor emission control system in accordance with USCG requirements. The purpose of the PV valve is to provide automatic safety control of pressure differentials during cargo operations and during the voyage and avoid damage

to the cargo tanks.

In order to meet the requirements of the calculated vapor flow capacity of 1,960m³/h, which is based on maximum loading rate in each tank, a single high velocity pressure relief valve is fitted on each cargo oil tank. The combined PV valves are mounted on their own individual vent pipes so that the top of the pressure valve is at a height approximately 2 meters above the deck level.

Function

During the loading of a cargo, the discharged atmosphere from each tank is discharged ashore via the vapour emission control (VEC) system, or if VEC is not being used, the cargo tank(s) atmosphere is directed to atmosphere via the vent mast riser. As a safety measure to protect each cargo tank in the event that the evolved vapour cannot be relieved at a sufficient rate, the pressure build up in the tank(s) lifts the pressure disc from its seat on the associated high velocity pressure valve, the excessive tank pressure is then relieved to the pre-set level.

On attaining the pre-set pressure the disc reseats itself.

During the unloading of a cargo, should a vacuum build up in a tank(s) the vacuum disc lifts from its seat on the associated high velocity pressure vacuum valve, the tank(s) vacuum is then relieved to the preset limit. On attaining this preset limit the disc reseats itself.

As per SOLAS requirements, both the high velocity pressure and vacuum valves must be tested before the commencement of cargo operations.

To check the operation of the overpressure valve, operate the check lifting handle, located on the side of the valve body side to side and then return it to the central position.

Check lifting of the vacuum valve is accomplished by pushing up on the check lift spindle. Both valves are self-closing when in the properly maintained condtion.

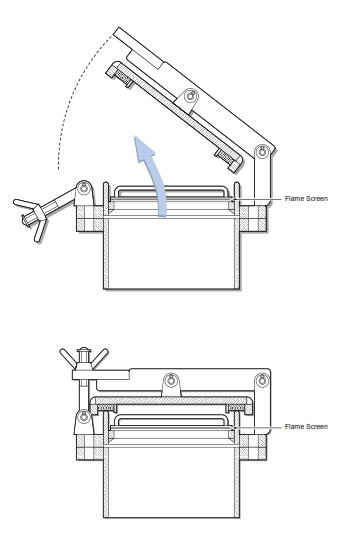

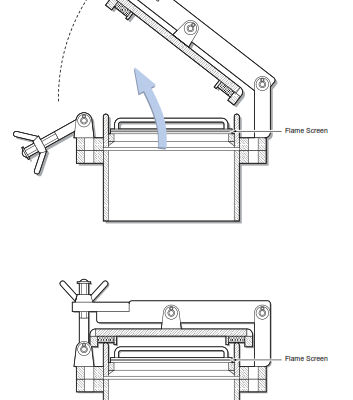

During cold weather operations, regular checks should be made to ensure that the pressure/vacuum valves do not get blocked by ice coverings which would otherwise inhibit the correct functioning of the valves. Flame screens can also become blocked when humid air vented from a cargo tank condenses and freezes on the gauze flame screens.

Each cargo tank is also fitted with a gas freeing pipe with a swing lid and a flame screen at the top.