Description

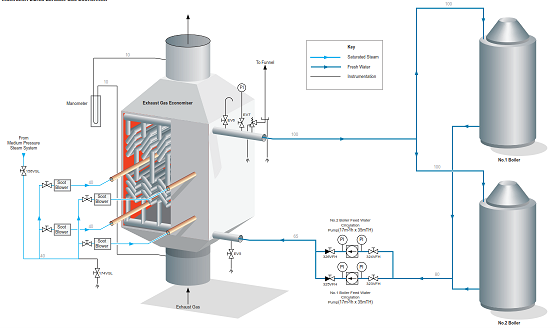

The exhaust gas boiler, which is located in the engine room at the upper deck level, is used to generate steam from the waste heat in the main engine exhaust gas. It can be operated separately or in connection with the oil fired auxiliary boilers.

The steam generating tubes are of the pin tube type and the tube nest is located in a welded steel shell through which the engine exhaust gas passes. Water is circulated through the steam generating tube nest and some of the circulating water is converted into steam. The emulsion of steam and water flows back to the auxiliary oil fired boiler from which the water was taken by one of the boiler water circulating pumps. In the boiler the steam is separated from the water and supplied to the steam main.

There are two boiler water circulating pumps with only one normally operating. Water circulation is continuous and the amount of steam generated depends upon the amount of heat energy in the main engine exhaust gas. Any steam generated by the economizer in excess of the sea going demand is normally dumped to the atmospheric condenser in order to maintain the correct steam system pressure.

One of the boiler water circulating pumps should be operating at all times when the main engine is running and a pump should be started 30 minutes before the main engine is started. The pump should remain running for at least 6 hours after the main engine is stopped. Pumps should never be stopped if a soot fire is burning unless water is leaking from the tube in the boiler.

The surfaces of the tubes in the exhaust gas flow will become coated with soot and this will reduce the heat transfer and hence reduce the efficiency of the economizer.

A sootblower must NEVER be used to extinguish a soot fire and sootblowers must not be used if a soot fire is burning. The sootblower steam will disperse the burning embers through the uptake and on to the deck. If the fire involves metal, the introduction of steam on to burning metal will create a breakdown of hydrogen and oxygen, which will feed the combustion.

The economizer may be run in the dry condition in an emergency. If there is serious leak the boiler is to be drained of water and operated as a silencer and not as a steam generator.

There is an increased risk of a soot fire when operating in the dry condition as there is no cooling effect from the water. Prior to dry running the tubes should be water washed in order to remove soot deposits.

The main engine should be operated at full power and low speed operation should be avoided as this increases the risk of soot deposits.

When dry running the soot blowers should be operated 5 – 6 times per day in order to keep the tube surfaces clean.

Operating Procedures

The following steps should be taken before attempting to operate the exhaust gas economizer. It is assumed that at least one auxiliary boiler is operating:

a) All foreign materials are to be removed from internal pressure parts.

b) Ensure all gas side heating surfaces are clean.

c) Ensure all personnel are clear.

d) All manhole covers are to be securely tightened.

e) Inspect safety valves and see that gags have been removed and easing levers are in good condition.

f) Open root valves for all instruments and controls connected to the boiler.

g) Open the vent valve at the boiler top.

h) Open all pressure gauge valves and check to see that all valves on the pressure gauge piping are open.

i) Check and close all drain valves and inspection hatches.

j) Set up the valves as per below:-

- Open No.1 boiler water circulating pump suction valve

- Open No.1 boiler water circulating pump discharge valve

- Open No.1 boiler water circulating pump recirculation valve

- Open No.2 boiler water circulating pump suction valve

- Open No.2 boiler water circulating pump discharge valve

- Open No.2 boiler water circulating pump recirculation valve

- Open Suction valve from No.1 auxiliary boiler

- Open Steam/water return valve to No.1 auxiliary boiler

- Open Suction valve from No.1 auxiliary boiler

- Open Steam/water return valve to No.1 auxiliary boiler

One of the boiler water circulating pumps can then be started. If the system is prone to water hammer at this stage, it may be advisable to start the pump with the discharge valve throttled in, gradually opening the valve as the exhaust gas economizer warms up. Slowly open the control valve and gradually fill the exhaust gas economiser tubes

If the exhaust gas economizer is already hot when it is being filled (due to main engine operation) the feed water must be introduced slowly in order to prevent sudden cooling of hot surfaces.

When the load from the main engine has increased to normal, the exhaust gas economizer can now generate sufficient steam to supply the vessel’s services. The auxiliary boiler firing is then stopped.