Purpose

- Every oil tanker of 150 gross tonnage and above

- Every ship of 400 gross tonnage and above other than an oil tanker

Is provided with an Oil Record Book Part I, (ORB) to record oil transfer operation in machinery space as per regulation 17 of MARPOL annex I

This is necessary in order for authorities to be able to monitor if a vessel’s crew has performed any illegal oil discharge at sea.

Oil record book is retained onboard for 3 years from the date of last entry.

The items to be recorded are listed below:

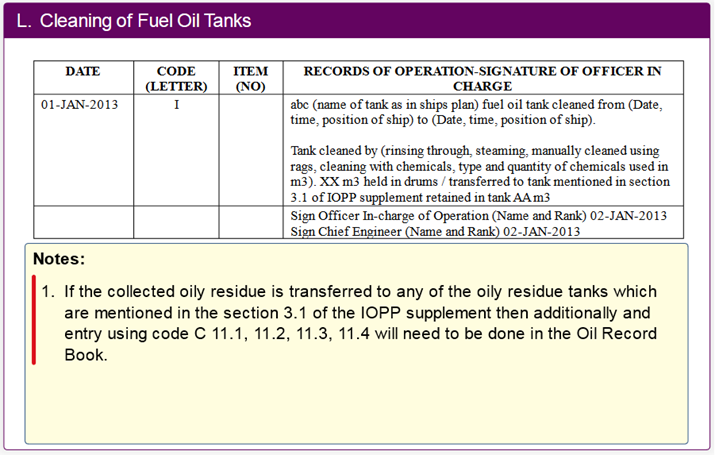

A – Ballasting or cleaning of oil fuel tanks

B – Discharge of dirty ballast or cleaning water from oil fuel tanks referred to under section (A)

C – Collection, transfer and disposal of oil residue (sludge and other oil residue)

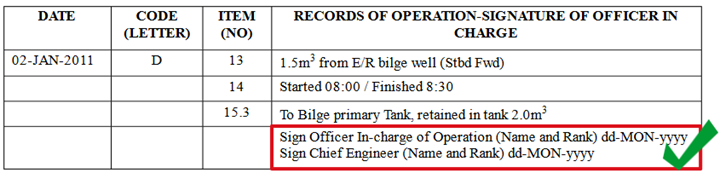

D- Non Automatic discharge overboard , transfer or disposal otherwise of bilge water which has accumulated in machinery spaces

E- Automatic starting of discharge overboard, transfer or disposal otherwise of bilge water which has accumulated in machinery space

F- Condition of oil filtering equipment

G- Accidental or other exceptional discharges of oil

H- Bunkering of fuel or bulk lubricating oil

- Additional operation procedures and general remarks.

Responsibility

All officers and crew onboard need to recognize that recording of ORB is required by the rules and the records are critical.

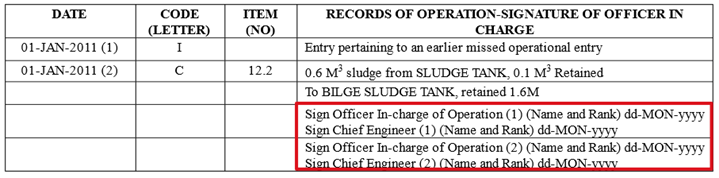

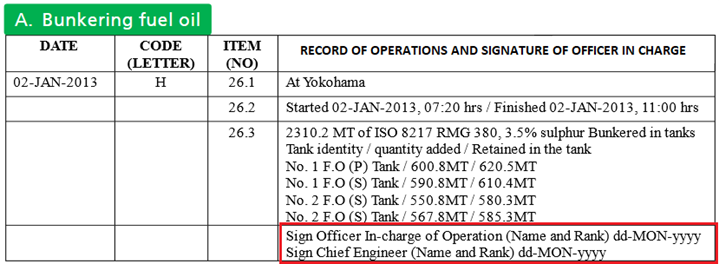

In Oil record book part I, Each completed operation shall be signed by the engineering officer in charge and confirmed by the chief engineer.

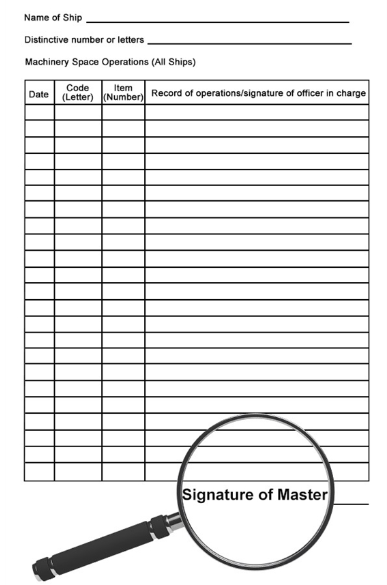

The master will sign at the bottom of each completed page.

Person carrying out the operation

Operations which have the possibility to result in:

- Discharge overboard

- Overflow of oil from tank

Shall be carried out by a certified watchkeeping engineer (duty engineer ) only.

Other operations which cannot result in a discharge overboard or tank overflow may be carried out by a junior engineer acting under the direct supervision of a certified watchkeeping engineer.

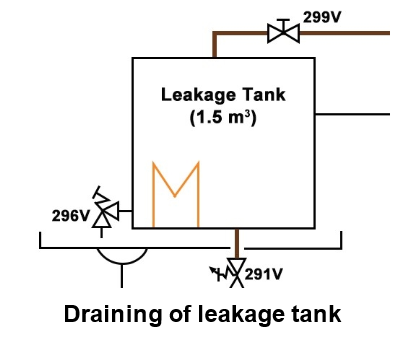

An example of this is the draining of a leakage tank to a sludge tank with verified available capacity.

Pumping operations should be carried out only by a certified watchkeeping engineer, especially where error in valve operation is possible.

Each completed operation shall be signed by the engineering officer in charge and confirmed by the chief engineer. The master will sign at the bottom of each completed page.

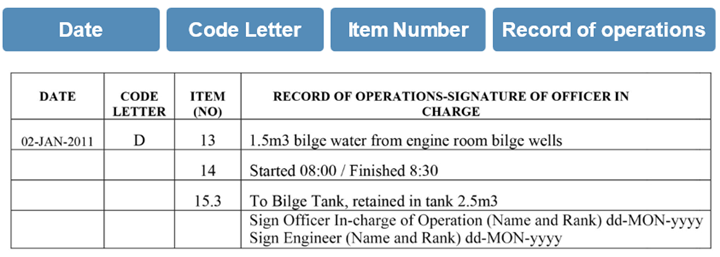

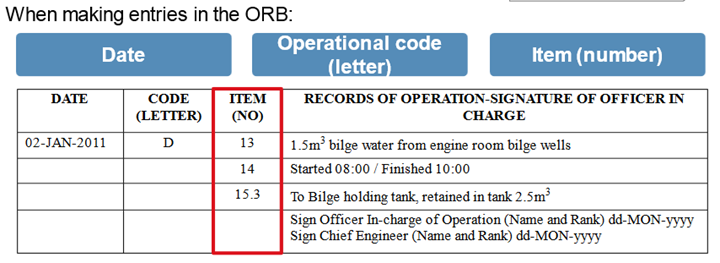

Oil record book (part I) – Entries

When to make the Oil record Book Entry

ORB entry must be made immediately on completion of the operation in English.

When making entries in the ORB:

Item numbers shall be inserted in the appropriate columns chronologically.

Where a duty engineer makes a number of similar transfers in the course of a watch, it is acceptable to enter the total sum of the transfer into the ORB as a single entry.

An example of this might be several bilges pumped from the same space to the same bilge holding tank.

The period covered must not exceed six hours and the entry must make it clear that the transfers were made over such a period.

Person making the Entry

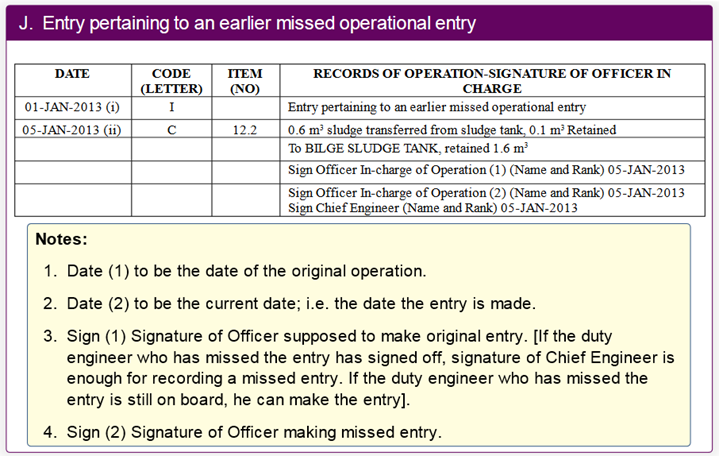

The person making the entry into the ORB must be the person who is directly responsible for carrying out that particular operation.

Normally this would be a duty engineer.

Each completed operation shall be signed by the engineering officer in charge and confirmed by the chief engineer. The master will sign at the Bottom of each completed page.

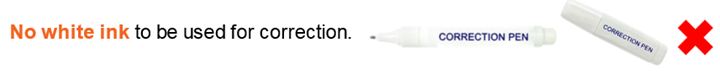

Inedible Entries

All entries in the ORB have to be recorded with indelible ink.

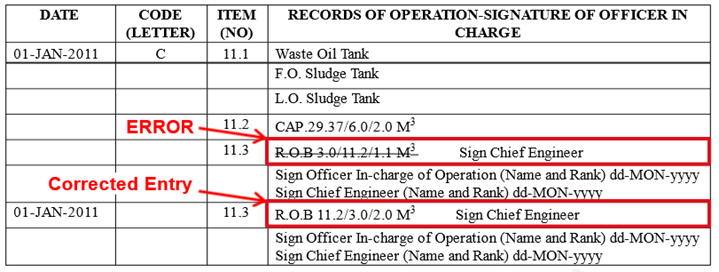

Correcting wrong entries

In case wrong entry has been recorded in the ORB, it should be struck through immediately by a single line such that wrong entry can still be read

The wrong entry will be signed by the officer in charge, and the new correct entry is to be made at the first clear line available below.

Post entry amendment

Each entry must be checked and signed at the earliest opportunity by the chief engineer for accuracy and content. Any necessary amendments are required to be made within 24 hours of the operation carried out.

Amendments are acceptable provided that they are endorsed by both the chief engineer and the duty engineer responsible for the operation.

Each completed and checked page of the ORB must be presented to the Master for endorsement without delay i.e at the first opportunity during his working day.

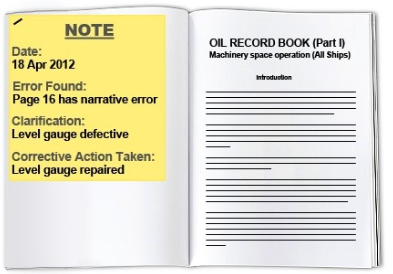

Error found at a Later Date

If at a later date, ORB entries are found to be in error or require to be clarified (such as during an audit or internal review), a note of the relevant findings and any corrective actions is to be attached to the inside cover of the relevant ORB.

No further action is necessary

The presence of the findings should be accepted by third parties as proof of effective audit and review procedures and the affected entry should not be construed to be a current deficiency in the ORB.

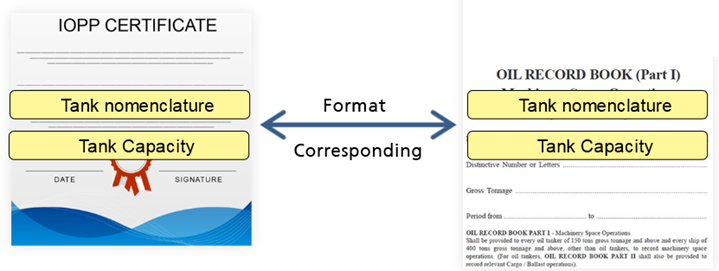

ORB Entries and IOPP Certificate

Entries in ORB such as:

- Tank nomenclature should be recorded as per the format noted within the IOPP certificate

- Capacity of the tank should be recorded as corresponding with the capacity of the tank written in the IOPP certificate.

- Oily water separator discharge must not exceed the discharge rate shown in IOPP certificate.

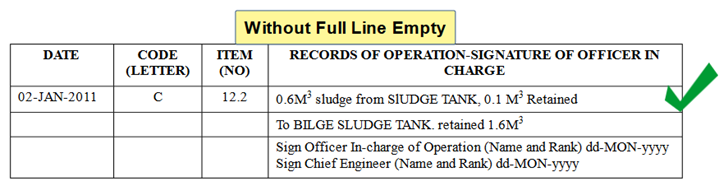

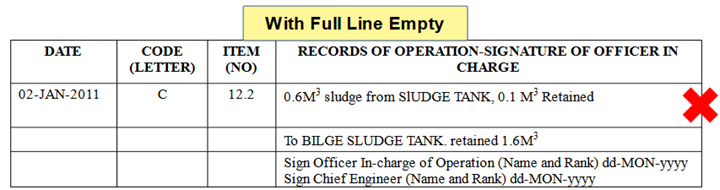

ORB Entries and space

It is not permitted to leave any full lines empty between entries (it might possibly become a target of suspicion, with a full line giving space to add a false entry for the purpose of modifying the record.)

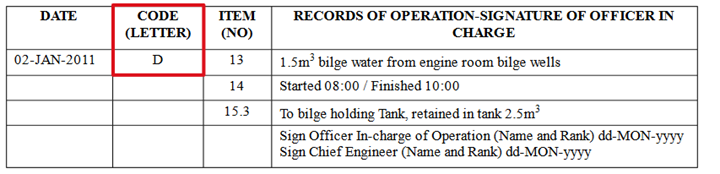

Code Letter

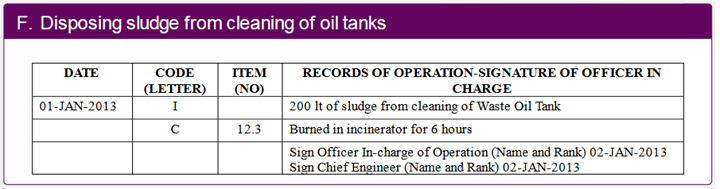

It is essential that the appropriate code letters are assigned, in order to identify the type of liquid being transferred.

Code “D” or “E” must be assigned where bilge water is concerned.

For example, code “C” must be assigned where oil residues and sludge are concerned.

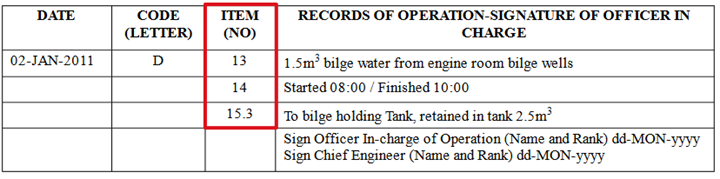

Item Number

The item number must be chosen with great care, as experience has shown that the item number is often differently interpreted by third parties.

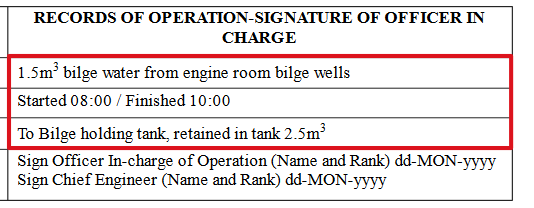

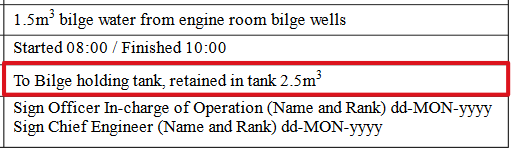

Record of Operations

Care must be taken to ensure that the record clearly identifies the exact operation which has been carried out.

Supporting relevant information such as quantity, start and stop time, position etc. must be supplied as required.

Acceptable standard of Entry

Every effort must be made to ensure that the correct date, code letter, item number, record of operations and signatures are entered when making the ORB entry.

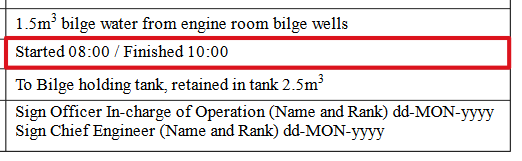

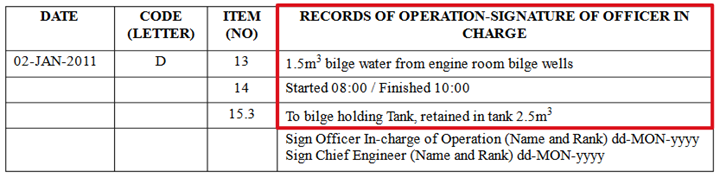

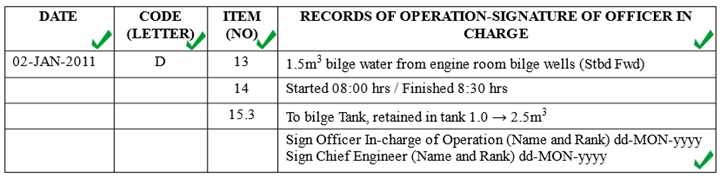

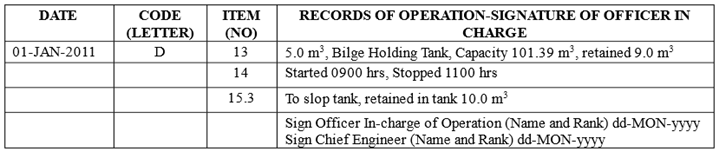

Transfer of bilge water to the bilge holding tank (if bilge primary tank is not fitted or not used)

Al five items are required to be entered before the entry can be considered to be complete.

- The flag state require that the (i) Date (ii) Code letter (iii) Item number and (iv) Record of operations clearly identify the potential pollutant and the associated operation which has been carried out, with (v) signature of officer in charge.

- With above required information given, the requirement of the ORB entry has been satisfied.

Automatic and Non Automatic discharge of disposal

Confusion has arisen regarding:

The term Non-automatic is deemed to refer to the mode of starting, rather than a description of the capabilities of the system in operation.

For example, if a system fitted with automatic recirculating, alarm and stop functions is manually started, then entries under “D” are appropriate.

Code “E” is applicable if the vessel is fitted with automatic bilge discharge system, in which case the bilge pump starts automatically as the bilge well level goes high.

Other methods

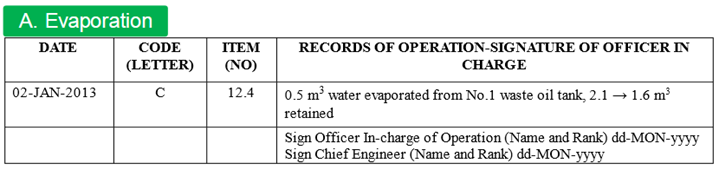

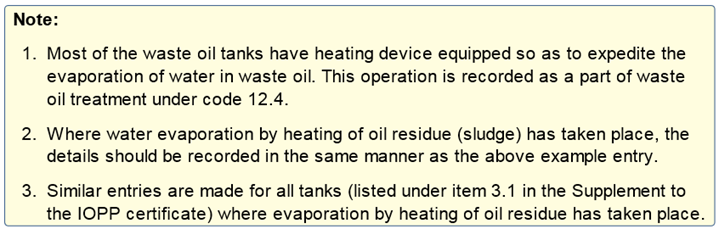

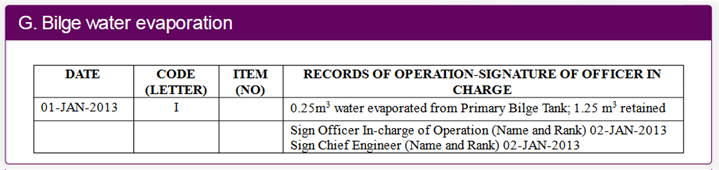

Other methods of disposal (code of C, item no 12.4) have to be recorded for e.g evaporation loss of water from waste oil setting tank

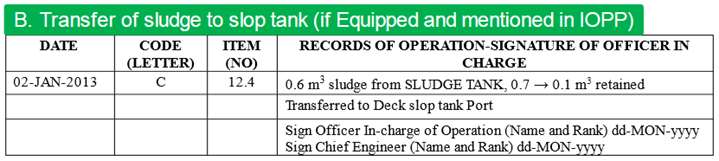

Discharge Bilges to Slop Tanks : Code letter “D”

If a vessel has an approval for discharging engine room bilges to slop tanks, entry must be made both in ORB (Part I), code letter “D” & item numbers 13,14,15.3, as well as ORB (Part II, code letter J) in case of such transfers.

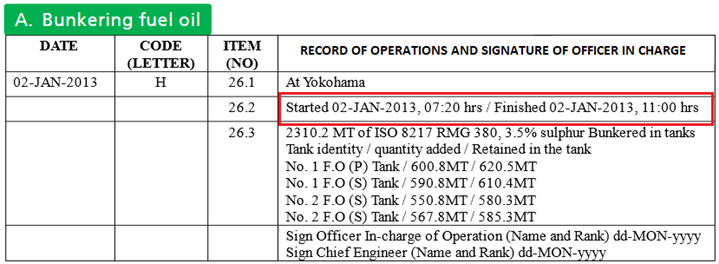

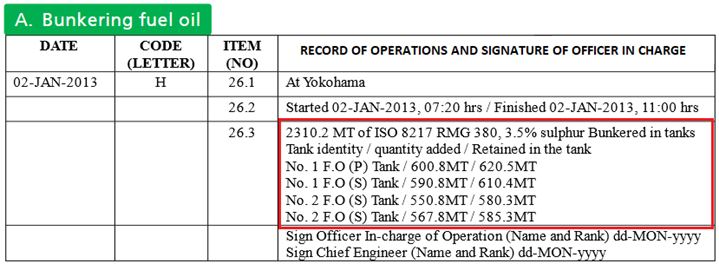

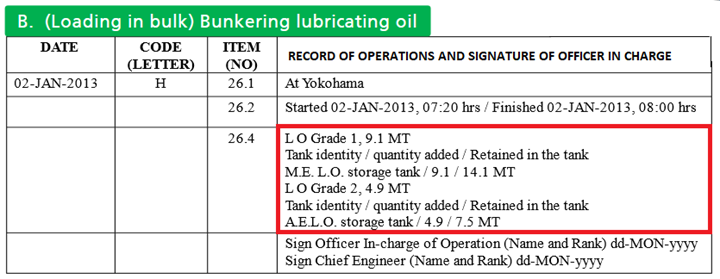

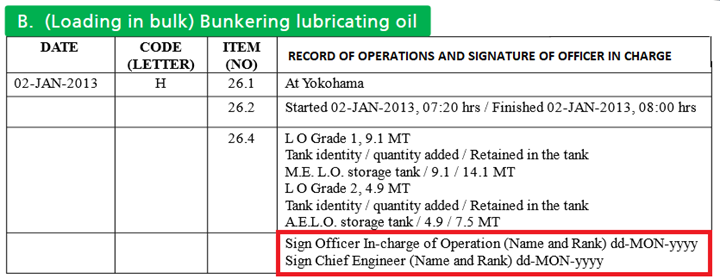

Bunkering of Fuel or Bulk Lubricating Oil : Code Letter “H”

- Place of bunkering

- Time of bunkering

- Type and quantity of fuel oil and identity of tanks (state quantity added, in tonnes and total content of tanks)

- Type and quantity of lubricating oil and identify tanks (state quantity added, in tonnes and total content of tanks)

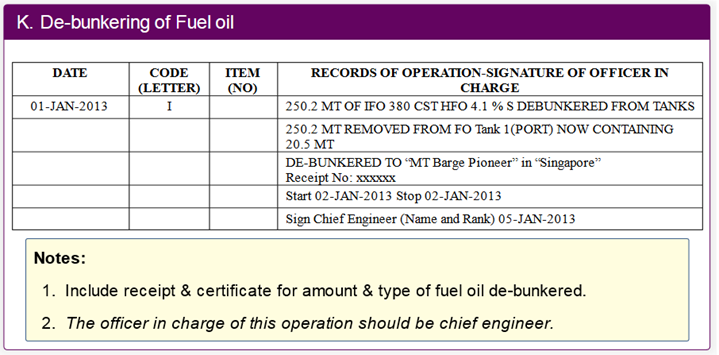

- In case fuel oil and/or lubricating oil is un-loaded onshore (de bunkering) for some reason, this should be recorded in code “I”

- As for lubricating oil, however, it does not have to be recorded of the oil in drum is loaded, for instance (i.e not loaded in bulk)

- Start and finish time shown above should match with the bunker delivery note.

- The total quantity loaded should also match with the quantity shown on the bunker delivery note.

- In case you have taken diesel oil also, please make a complete separate entry as you will have a separate bunker delivery note for diesel oil.

- The officer in charge of the operation under code-H should be chief engineer.

- All the different graded of bulk lubricating oil received can be recorded in a single entry.

- The quantity has to be entered in metric tons, therefore multiply the volume of the lube oil with the specific gravity. (refer to your lube oil supplier manual) in order to get the metric tons (MT)

The officer in charge of the operation under code-H should be chief engineer.

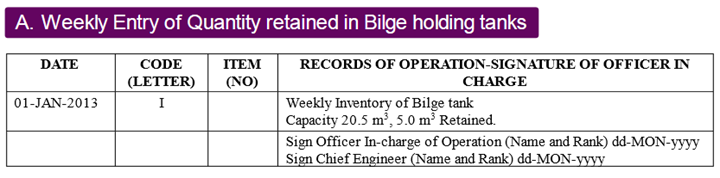

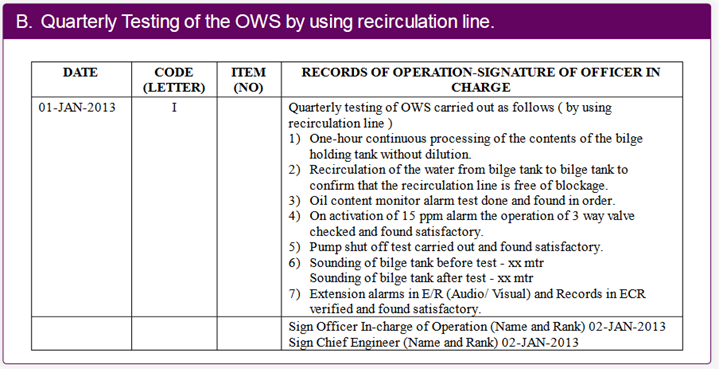

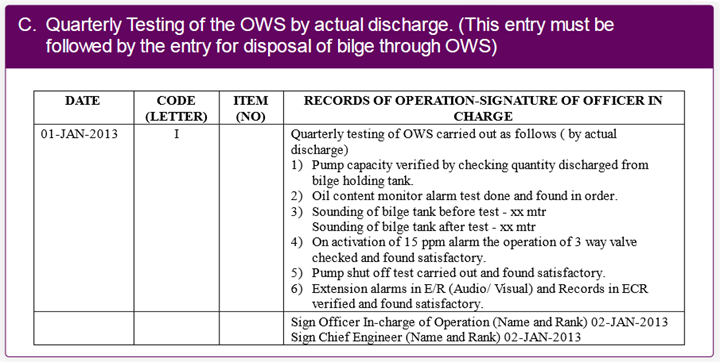

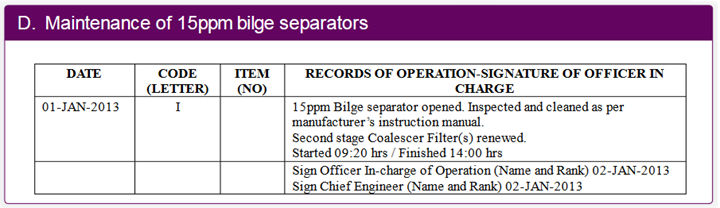

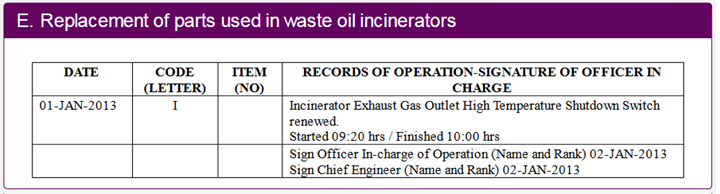

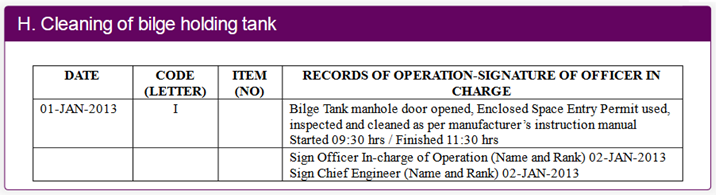

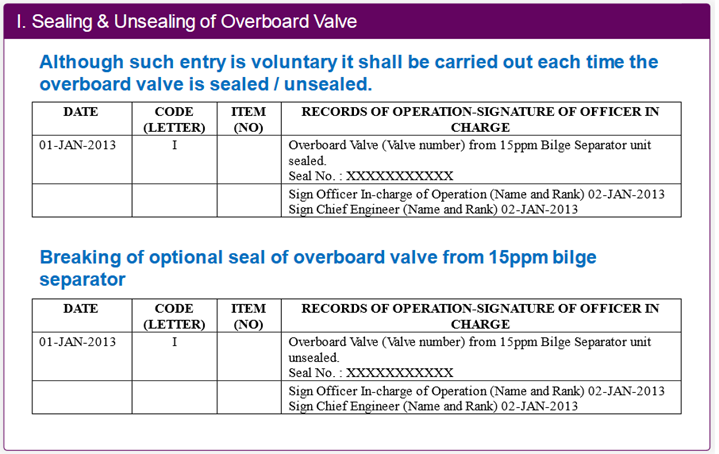

Additional operation procedures and general remarks code letter “I”

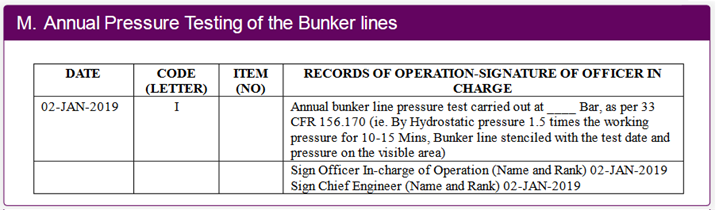

- Items such as maintenance of bilge separators and operational test for oil content monitor which are equipment listed in IOPP certificate supplement, specifically on how they were carried out.

- However, it excludes contents related with the daily maintenance such as cleaning of bilge suction strainers.

- There are no codes for specific tasks, so record must be clear and to the point. Refer to the sample entries below for more details.

- According to the MEPC circular (MEPC.1/Circ.640/Rev.2), the quantities retained on board in bilge holding tanks should be recorded weekly.

Specific Guidelines for Masters and Chief Engineers

- ORB must be duly recorded and signed (after each completed entry, both duty engineer and Chief engineer to sign)

- Master to sign each completed page.

- The ORB part I should be shown to the PSC (or any authorized person) in the presence of the chief engineer and all the questions related to the entries made, must be answered directly by him.

- The ORB part I is kept in the personal custody of the chief engineer and he is responsible for the proper upkeep of the oil record books.

- Certificate and instruction manuals of following equipment’s must be readily available with the chief engineer.

- 15ppm bilge separator

- Oil content monitor

- Automatic stopping device

- Waste Oil incinerator

- Aux boiler in case if used for waster oil incineration

- ODMCS

- The IOPP certificate and supplement must be readily available with chief engineer for corss verification with the ORB by the PSC inspector.

- The receipts obtained after discharging waste oil or dirty water to shore facilities must be kept in the safe custody of the chief engineer, attached to ORB.

- Shore facility discharging receipt

- Main engine air cooler condensation can be large quantity especially in tropical climates. (Please ensure that this water is disposed through 15ppm equipment unless there is dedicated clean water tank for collecting this clean water.)

- A copy of schematic pipeline diagram for bilge and sludge system should be displayed near OWS and one additional copy should be available with the chief engineer for reference. The same is applicable for ODMCS which should be available with chief officer.

- At least one spare new copy of ORB must be available onboard.