Comparision of Hague Visby – Hamburg and Rotterdam Rules.

Hague Rules 1924 Hague-Visby Rules 1968 US COGSA 1936 Hamburg Rules 1978 Rotterdam Rules 2009 Scope of application Bills of Lading issued in a contracting state. a) B/L issued in a contracting stateb) Carriage is from a Port in a contracting statec) Contracts of carriage which incorporate the Rules Shipments to and from the United…

Read More “Comparision of Hague Visby – Hamburg and Rotterdam Rules.” »

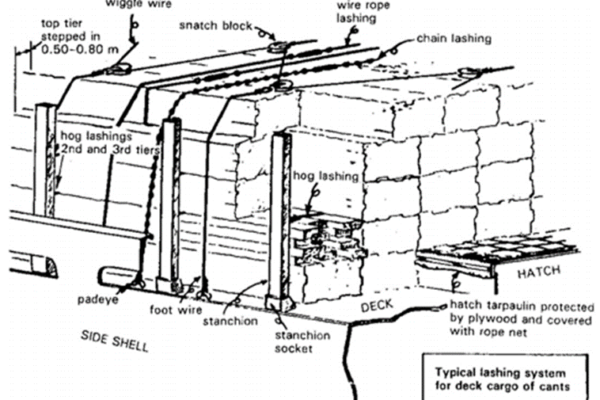

Carriage of Timber Cargo

•Timber – means sawn wood or lumber, cants, logs, poles, pulpwood and all other types of timber in loose packaged forms but not including wood pulp or similar cargo. •Cant – means a log that is cut in slabs, so that two opposite or sometimes three sides are flat and the other(s) curved. •Timber Deck…

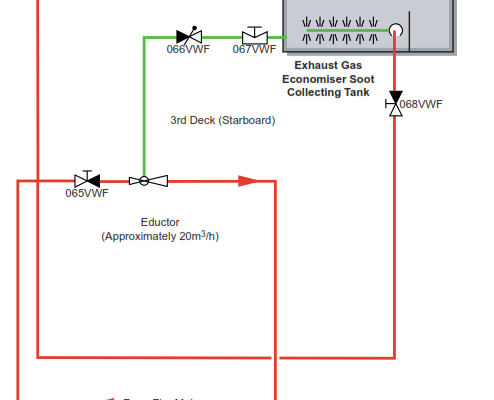

SOOTBLOWERS AND BOILER CLEANING

Oil Fired Auxiliary Boilers The oil fired auxiliary boilers are not fitted with sootblowers. Soot removal from the heat transfer surfaces of the tubes is carried out by means of a water jet when the boiler is not in operation. The need for soot removal may be determined by the following procedures: • Visual inspection…

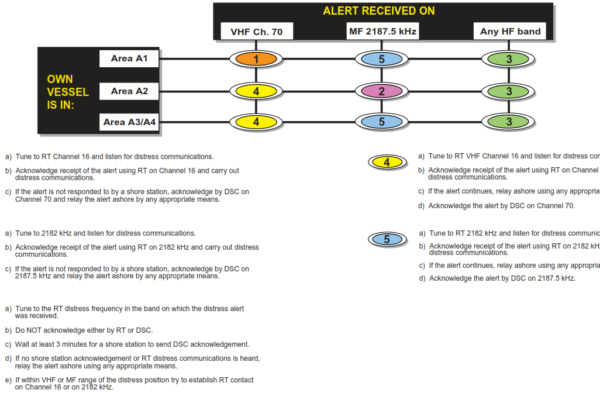

GMDSS

The Global Maritime Distress and Safety System (GMDSS) is an international system relating to all vessels over 300 gross tonnes and all passenger vessels engaged on international voyages, irrespective of tonnage. It provides comprehensive communications for distress, urgency and safety operations in the terrestrial and satellite services. It specifies methods to be used to enable…

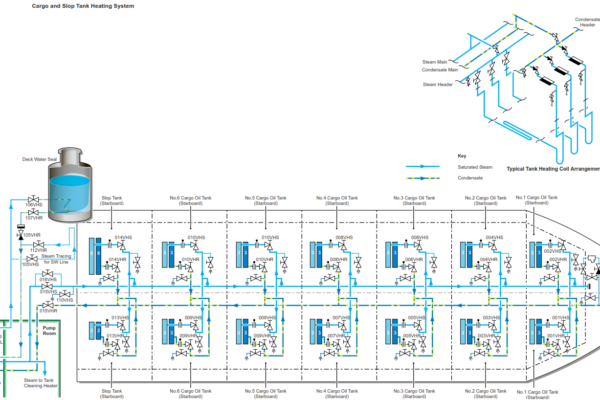

SLOP TANK AND CARGO TANK HEATING

Both the port and starboard slop tanks are fitted with internal grid type heating coils. The port slop tank has eight coils fitted while the starboard slop tank has only two coils fitted. The cargo oil tanks each have three coils. The coils are supplied with 0.9MPa saturated steam from the engine room and the…

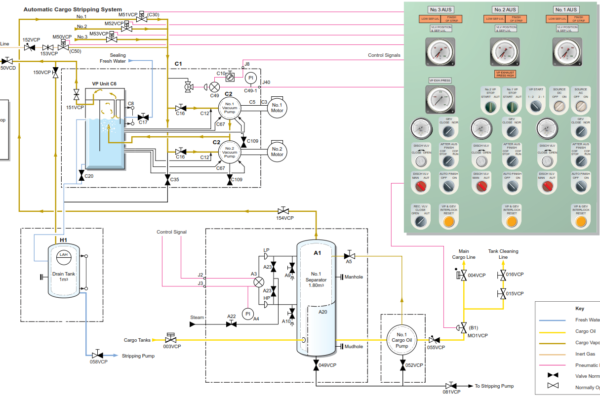

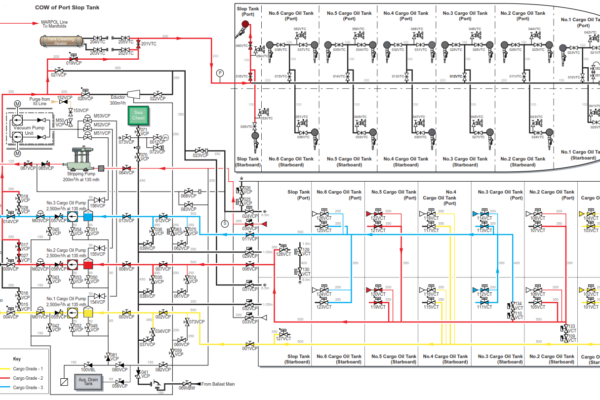

AUTOMATIC CARGO STRIPPING SYSTEM

System as per my present vessel The automatic cargo stripping system is provided to improve the efficiency of stripping the cargo oil tanks and to assist in the maintenance of high bulk rate discharge. It utilises the cargo oil pumps to complete the stripping operation which reduces unloading time. The operation is fully automated. The…

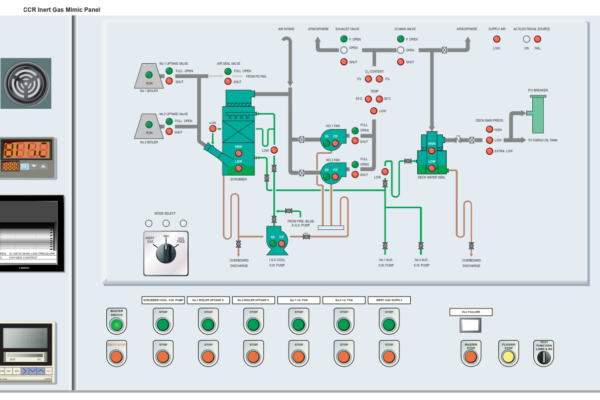

OPERATION OF THE INERT GAS SYSTEM

The flue gas system main control panel is situated in the CCR. This panel contains the programmable controller pushbuttons etc, which takes care of the start/stop/alarm functions and the running mode. On the front of the panel the system is represented in the form of a mimic diagram, with appropriate indications and pushbuttons. The panel…

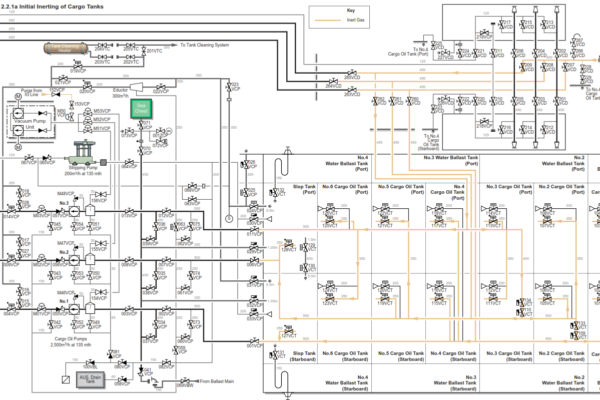

Inerting Cargo Tanks

System explained basis my present vessel. INITIAL INERTING Under normal operating conditions the vessel is kept totally inerted. However, after refit or tank inspections some, or all, of the tanks may be gas free. Prior to any cargo operations all COTs must be inerted and this is normally completed en route to the loadport. Good…

DISCHARGING CARGO

System described basis my present vessel FULL DISCHARGE The following factors are to be considered prior to a full discharge: • Maximum available draught at the berth • Maximum allowable freeboard on the berth • Grade segregation, if carrying multiple grades • Crude oil washing requirements • Heavy weather ballast requirements • Maintenance of satisfactory…