Gas tankers—whether carrying LNG (Liquefied Natural Gas) or LPG (Liquefied Petroleum Gas)—transport some of the most complex cargoes in the maritime industry. Unlike crude oil or dry bulk, these cargoes are highly sensitive to temperature, pressure, and density variations, making accurate cargo calculations essential for safety, efficiency, and commercial transparency.

🔹 Why Cargo Calculations Matter

- Commercial Accuracy: Ensures correct billing and prevents disputes between charterers and shipowners.

- Safety: Incorrect calculations can compromise vessel stability and lead to dangerous situations.

- Efficiency: Helps optimize loading, discharging, and voyage planning.

🔹 Step-by-Step Cargo Calculation Process

1. Volume Measurement

- Cargo levels are measured using radar gauges or manual soundings.

- Tank calibration tables convert these levels into volume at observed temperature.

2. Density Correction

- Density is referenced at 15°C (standard condition).

- Corrected using ASTM tables to account for actual cargo temperature and pressure.

3. Mass Calculation

- Calculated separately for liquid cargo and vapour cargo.

- Vapour contribution is significant in LNG carriers due to boil-off gas.

4. Discharge & Remaining Onboard (ROB)

- Compare initial and final tank measurements.

- ROB is carefully documented for charter party agreements.

🔹 Operational Challenges

- Temperature Sensitivity: LNG at -162°C expands rapidly with small temperature changes.

- Pressure Variations: Vapour pressure affects density and measurement accuracy.

- Free Surface Effect: Liquids in partially filled tanks reduce vessel stability.

- Sloshing: Liquid movement can damage tanks and distort readings.

- Unit Conversions: Confusion between metric tons, long tons, and short tons can cause disputes.

🔹 Best Practices

- Always use ASTM tables for density corrections.

- Apply Vessel Experience Factor (VEF) to align with historical performance.

- Train crew on free surface effect and sloshing dynamics.

- Record all readings (temperature, pressure, soundings) for transparency.

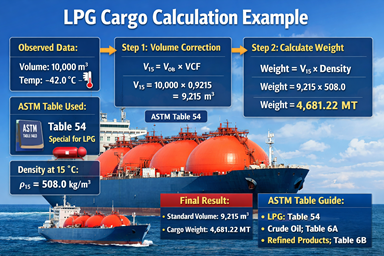

Example

Cargo: Propane

Ship type: Fully refrigerated LPG carrier

Observed tank liquid volume (Vobs): 10,000 m³

Observed liquid temperature (Tobs): –42.0 °C

Tank pressure: Fully refrigerated (pressure not used for volume correction)

Density at reference temperature (15 °C): 0.5080 kg/L

Reference temperature: 15 °C

2. Identify Correct ASTM / API Tables

For liquefied petroleum gases (LPG) like propane, butane, ammonia:

| Purpose | Table Used | Reason |

|---|---|---|

| Volume correction for LPG | ASTM/API MPMS Table 54 | Specially designed for LPG |

| Density correction | ASTM Table 54D | LPG density correction |

| Weight calculation | Density × corrected volume | LPG custody practice |

❌ Do NOT use Tables 6A / 6B / 53

Those are for crude oil and refined petroleum products, not LPG.

3. Step 1 – Correct Observed Volume to Standard Volume

Why correction is needed

LPG volume changes significantly with temperature.

We must convert observed volume at –42 °C to standard volume at 15 °C.

Use:

ASTM Table 54 – Volume Correction Factor (VCF)

From Table 54 (Propane):

- Temperature: –42 °C

- VCF (–42 °C → 15 °C): 0.9215

Calculation:

V15 = Vobs × VCF

V15 = 10,000 × 0.9215

V15 = 9,215 m³

✔ Standard volume at 15 °C = 9,215 m³

4. Step 2 – Density at Standard Temperature (15 °C)

For LPG, density is normally given or calculated at 15 °C.

Given:

Density at 15 °C = 0.5080 kg/L

Convert to kg/m³:

0.5080 kg/L × 1000 = 508.0 kg/m³

✔ ρ15 = 508.0 kg/m³

5. Step 3 – Calculate Cargo Weight (Metric Tons)

Formula:

Weight (kg) = V15 × Density

Calculation:

Weight = 9,215 × 508.0

Weight = 4,681,220 kg

Convert to metric tons:

4,681,220 ÷ 1000 = 4,681.22 MT

✔ Cargo weight = 4,681.22 Metric Tons

6. Final Cargo Calculation Summary

| Item | Value |

|---|---|

| Observed volume | 10,000 m³ |

| Observed temperature | –42 °C |

| ASTM table used | ASTM Table 54 |

| Volume at 15 °C | 9,215 m³ |

| Density at 15 °C | 508.0 kg/m³ |

| Final cargo weight | 4,681.22 MT |

7. Which ASTM Table to Use – Quick Guide

| Cargo Type | ASTM / API Table |

|---|---|

| Propane / Butane / LPG | Table 54 |

| LNG | Special LNG tables (not ASTM 54) |

| Crude Oil | Table 6A |

| Refined Products | Table 6B |

| Chemicals | Table 54 or specific chemical tables |

8. Common Examiner / Surveyor Questions

Q: Why not Table 6A for LPG?

👉 Table 6A assumes low thermal expansion, LPG has very high expansion.

Q: Is pressure correction required?

👉 No for fully refrigerated LPG cargo.

Q: Which density is used for final weight?

👉 Density at 15 °C only.