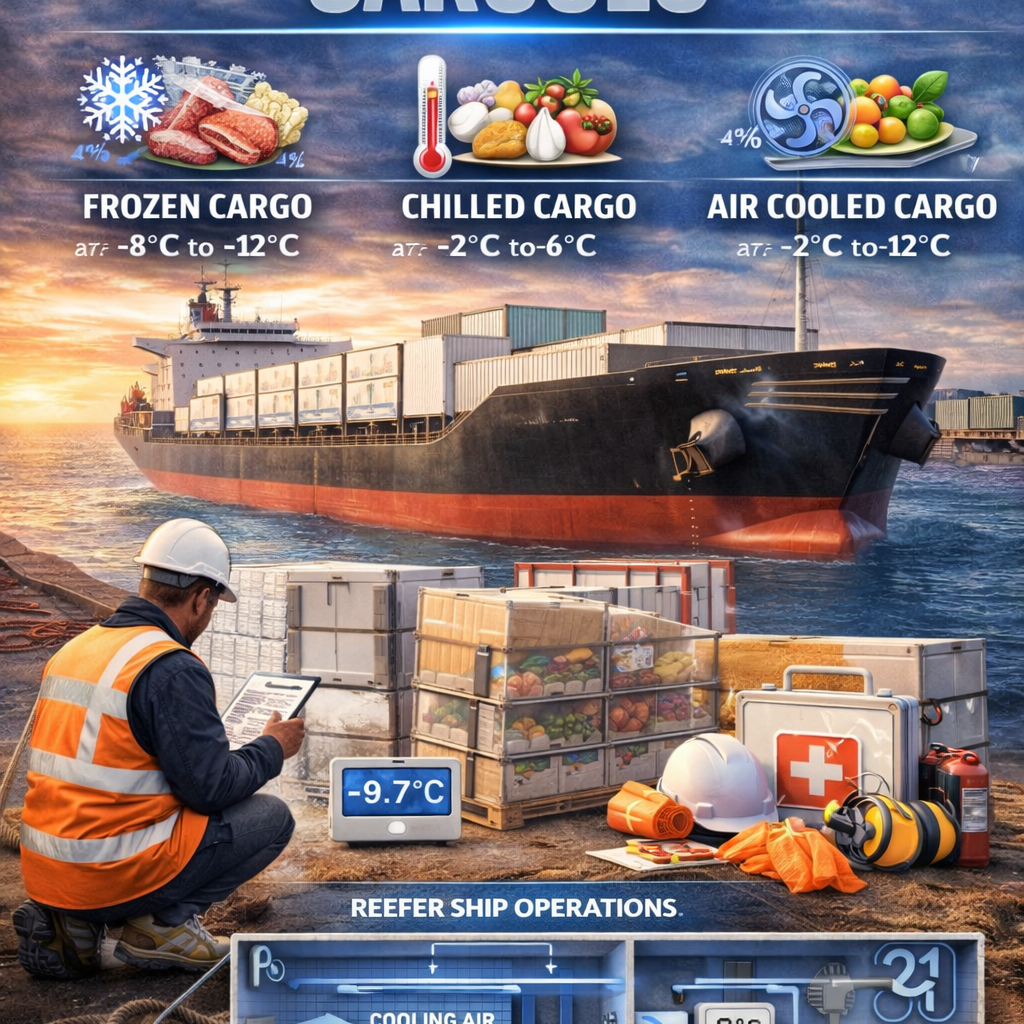

Refrigerated Cargoes Classes

Refrigerated Cargoes can be divided in to three classes.

Frozen Cargo: eg. Meat, Butter, Poultry and Fish. These cargoes are carried in a hard frozen state at temperatures around -8 Deg Centgde to -12 Deg Centgde to prevent growth of bacteria.

Chilled Cargo: eg. Cheese, eggs and fresh vegetables. Temperatures maintained in the compartment for these cargoes around -2 to 6 Deg Centgde. Maintaining the right temperatures is more critical with chilled cargoes than with frozen cargoes as condensation of moisture due to variation of temperatures encourages bacterial growth.

Air Cooled Cargo: eg fruits. Here temperatures of around 2 to 12 Deg Centgde are maintained by air circulation.

Refrigerated Cargo Operations

The success of refrigerated trade depends principally on the condition in which cargo arrives at the discharge port. This not only depends on the efficiency of refrigeration plant but also greatly depends on the efforts of the cargo officers with respect to loading, unloading, stowage and carriage precautions observed.

Preparation of the Compartment

The compartment must be clean, dry and free from any odour or taint. If necessary, it must be deodorised using ozone, sodium bicarbonate but strong disinfectants must not be used. Bilges are to be cleaned, deodorised and suctions checked.

The insulation and permanent dunnage is to be checked and repaired as necessary.

Scuppers are to be cleaned and brine traps checked, tested and re-filled. Brine traps prevent warm air from entering the compartment and cold air from escaping; at the same time allowing drainage of water.

Thermometers should be in position and ventilator plugs to the compartment fitted in place and tightly wedged.

All openings are to be sealed against entry of air.

Brine pipes are to be tested to ensure that they are not choked and that no leaks occur at the joints.

Pre-cooling of the Compartment

The compartment should be cooled down prior to loading, to a temperature slightly lower than the transit temperature. Dunnage laid in the compartment is also to be cooled before cargo is loaded, otherwise it will stain the cargo in contact with it.

When the compartment is ready for loading a survey is carried out by the cargo surveyor who inspects the compartment for cleanliness, fitness for the cargo to be loaded and condition and proper working of the refrigeration plant. If satisfied a loading certificate, showing the temperature of each compartment, is issued before any cargo is stowed in the space.

Reception and Loading of Cargo

Local port regulations should be known to ship’s officers with respect to opening and closing of compartments and accepted working temperatures for stevedores to avoid friction with them and delay to the ship.

The stowage should be so aimed so as to allow free circulation of cold air around the cargo.

The cargo should be secured in a seaway.

Clean cargo should not come in contact with dirty cargo.

The incoming cargoes should be checked for inherent damage. This can be done by taking random samples. Any overripe or damaged cargo must be rejected.

When loading a lower hold through a refrigerated t’ween deck, canvas or tarpaulins must be hung around the opening to restrict the escape of cold air.

Reception and Loading of Cargo

Temperatures must be maintained during stoppages for meals, etc.

During loading or discharging when the compartment is open frost may form onto the brine pipes. This must be brushed away onto tarpaulins and removed to prevent its falling on cargo and causing damage by wetting.

After loading, all outside accesses should be sealed with paper to ensure good circulation.

The hatch covers are normally self sealing. The shipper must provide the vessel with loading and carrying temperatures and any other special requirements.

Care of Refrigerated Cargoes During Transit

Temperature control is most essential and must be strictly maintained.

Daily records showing the temperature in each compartment are to be kept for each watch. Nowadays automatic temperatures recorders keep a continuous record of temperatures.

During transit of chilled meat, a ceratin amount of CO2 (10% by volume) is introduced to preserve the meat. Excessive CO2 can discolour the consignment. Hence it is essential to keep a record and control of CO2 concentration. An instrument called a thermoscope is used to monitor the concentration of CO2.

Conversely, in the case of fruits, the ripening of the fruit causes evolution of CO2, which, if present in concentrations above 5% spoils the fruit. This excess CO2 can be dissipated by allowing fesh pre-cooled air occasionally into the hold, taking care not to cause large variations in temperatures.

Care During Discharge of Refrigerated Cargoes

Prior to discharge a cargo surveyor is generally called to check the transit temperature and CO2 records. If the concentration of CO2 is higher than 7% the compartment must be vented with fresh air prior to man entry for discharge.

Refrigeration Systems

Just as the natural flow of water is from a high level to a low level, the natural flow of heat too is from a body at a high temperature to a body at a low temperature; and just as we would need a pump to reverse the flow or pump water upwards, we need mechanical work to be done or a heat pump to transfer heat from a body at a low temperature and give it away to a body at a high temperature. This is the principle of refrigeration.

In ship’s refrigeration systems, direct expansion and circulation of the refrigerant is not advisable except for small refrigerated chambers and provision stores. This is because in large installations it becomes difficult to monitor the pipes for leakages which would result in a wastage of expensive gas.

For large refrigeration systems we therefore use the indirect method and a second refrigerant. The primary refrigerant is used to cool a tank of brine and this cooled brine is then circulated through the compartment. Brine is chosen because of its low freezing point, 20° to 30°C, depending on its concentration and composition.

The brine is passed through separate grids surrounding the same compartment. If one grid is blocked or choked, the brine supply can be increased to other grids so that cooling will not be affected. Also different groups of grids, each with its own expansion valve is used to maintain different compartments at different temperatures by adjusting the flow of gas.

For fruit cargoes, not only cooling but also ventilation is to be carried out. For this, instead of circulating the brine around the compartments, air is passed over the brine grids and this cooled air is blown through ducts into the compartment. Cooling is often carried out by a combination of cold brine and cool air circulation.